Cool... glad I clicked (ie, my PS). Sorry - I'm feeling groggy after some (drug & alcohol free) days away camping.

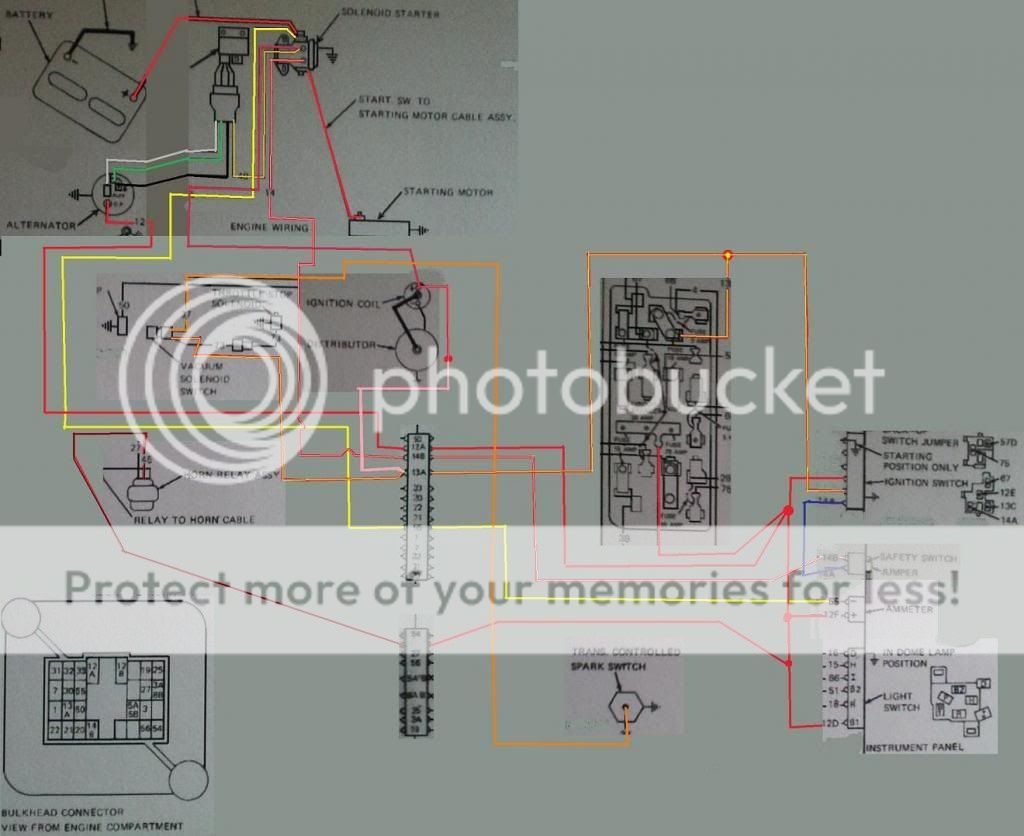

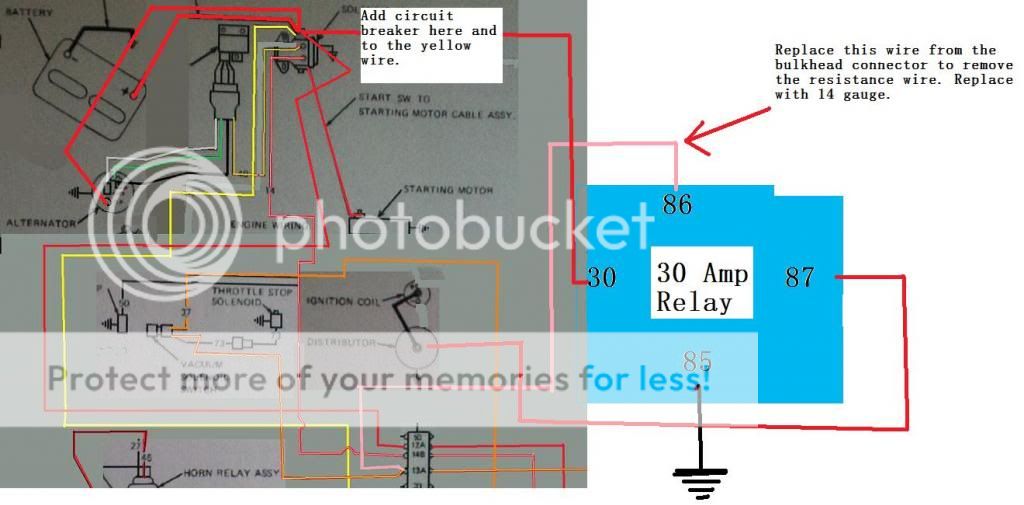

I endorse what Ween wrote - you should be able to power your HEI from the existing wire to the IgCoil ballast. That's IGN +12V.

Where I thought that wire was too small - or if I thought Ign or HEI noise injected back thru the wire to the IGN switch etc might cause unwanted noise and interference - I'd use the wire to turn on a typical automotive 30A relay (86 with 85 to GND) to connect the HEI +12V and igCoil+ (else igCoil's ballast resistor) to the battery - ie, 30 & 87 - with a suitable fuse (usually at least 15A, maybe 30A - but equal to or less than what current the wire and relay could handle).

You do not want to interrupt the alternator +12V output (usually called B or B+) to the battery +12V since that can cause electrical damage - especially on older alternators with external regulators.

[ Older alternators could go way over +16V without a battery connected. Newer alternators may limit their output to under 16V but without a battery connected there is nothing to filter +12V noise (switching relays, motors, etc) and voltage spikes can damage equipment, and furthermore the engine is likely to stall if there is a step change like flashers or brake lights etc.

]

I often recommend upgrading older external regulated alternators to modern alternators with integral regulators (specifically those with a dedicated "Sense" wire that goes straight to the battery +12V) since they exhibit far superior behaviour and overcome problems that can occur with external voltage regulators (eg, loss of or bad GNDs).

If the old system works then leave it. But when problems appear, IMO forget the common tail-chasing scenario of replacing the regulator, then the alternator, then the regulator again, and then BOTH the alternator & regulator and replace the lot with an

all in one modern alternator.

They merely have to physically fit (with aligned belt) and have at least the required output (Amps).

The wiring is usually easy... Upgrade the heavy B/B+ to battery +12V (maybe with a fuse close to the battery +12V which is to protect the battery & cable from a cable short - it rarely protects the alternator). Connect the L (or D+) charge light wire to the existing circuit - eg, into the appropriate pin/terminal of the old requlator's main harness connector. And connect the S (Sense) wire direct to the battery +12V terminal (that can be fused else merely use a thin cable which won't cause damage if it shorts & fuses).

If they also have an I or IGN terminal, that can also probably go to the old regulator's harness connector, or your igCoil +12V (igCoil+) etc - though most alternators are usually only S&L types and no longer use a dedicated I or Ig or IGN +12V signal, else only have the L = charge light known as D+ (but I usually recommend S&L types rather than the D+ only types).

Apologies if that's a lot of detail, but I hope it helps.

If unclear, please ask.

And I'd probably consider your own separate wiring. I haven't been impressed with the wiring of more recent Jeeps and I dread to think of Jeeps that are more than 20 years older....

Printable version

Printable version