Amp Rack On Top of Subwoofer Box

Printed From: the12volt.com

Forum Name: Car Audio

Forum Discription: Car Stereos, Amplifiers, Crossovers, Processors, Speakers, Subwoofers, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=68846

Printed Date: December 21, 2025 at 2:20 AM

Topic: Amp Rack On Top of Subwoofer Box

Posted By: hex0rz

Subject: Amp Rack On Top of Subwoofer Box

Date Posted: December 20, 2005 at 11:44 PM

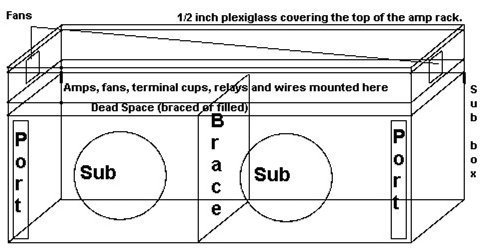

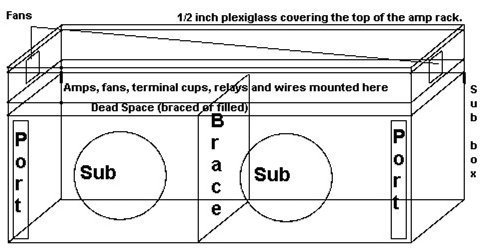

I'm hoping this subject is in the right area. I had an epiphany at work today... I'm building an amp rack ontop of my subwoofer box. Yes, I'am aware of the risk of the damage that can be done by this. I'm not too worried, since I have a solution, but 'am thinking there may be more solutions, that can also be better. The main problem to building an amp rack right on the box is the amount of vibration caused by the subs. Doing so is going to eventually damage your amp because of the intense vibration of the internal parts. Therefore, my mind has been racing for better solutions. I can come up with many different variations of the same idea, but it is for testing that which will really prove these really work. I would rather make pictures instead for all you to see, but I also think it should be sufficient enough to type this all out to you. Since I'm not the best at making pictures in mspaint. Haha! I believe it is a crucial thing to follow the experts of car audio. I AM NOT one these people. It is merely an elaborate and sophisticated idea from an audio enthusiast junkie. One of the best places of information regarding car aduio is: https://www.bcae1.com/ If you see here, he shows us a lesson of amp rack building. And the factor you must put in with construction. Here, he shows you the best places to put an amp for least vibration. It is however plausible that there may be better ways to reduce the vibration. The informer on this site is not technically dealing with the structure of the box. But rather the most ideal spot to mount your amp. Instead of amp placement, deal with the structural design of the box to lessen the vibration. My ideas(maybe a combination of all?): 1. Instead of mounting the amp right to the top of the box, put four blocks ontop of the wood and secure them down. However best you feel. (Me personally, I would use some gorilla glue and nail it in.) I would say then cover the top of these blocked piece with something like dyamat or some sort of rubber material so it will dampen vibration. I would also think that even an inch of foam pad would probably ideally work well too. Why I feel this will work. In this situation I apply the rule of surface area. I think that by reducing the surface area of the amp contact to the box, will in turn reduce the vibration of the amp. This in combination with say a strategic placement of the amp (if you have the ability) would in my mind, work quit well. 2. This idea has many different variations. Almost infinite possibilities. 2.1. Make a dead space between the amp rack and sub box. I would think that since the rack is not in direct contact with the surface of the box enclosure, there would be minimal vibration. 2.2 Same as 2.1. but instead of leaving it a dead space, fill it with some sort of deadening material. 2.3. Instead of leaving a dead space, make a cross hatch or a honeycomb style structure to put in between. Or many bracing boards... By doing this, you have less surface contact but also makes the box much more stable. (Then fill it with a material.) These merely are only curious ideas. I do plan on making some sort of solution for my own. I dunno which would be better out of these. I just need some sort of feedback from you all... I for one can say, that maybe this idea is not workable. Maybe it will cost too much money or time... ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Replies:

Posted By: Paradigm

Date Posted: December 21, 2005 at 2:13 AM

Raising the amp directly off of the sub box also allows for running cable underneath if you are limited on space, or want to hide the wires in some way. That is what I did on my box, and it worked spectacularly. The other thing that I did, and was required, actually, since I was using a triple-sub configuration, I had to make 3 seperate chambers, one for each sub. The two internal pieces served as extra bracing for the box, as well as being the dividers for each chamber. No other bracing was needed, and I think it is rather stout and won't flex (more due to the shape of the box itself than to the extra bracing, but both work to my advantage).  ------------- VEHICLE: 2002 GMC Sonoma ZR2

Alpine CDA-7940

AudioControl EQT x2

JL Audio 1000/1

JL Audio 10W6 (originals) x3

Kicker ZR120

Kicker ZR460

Polk GXR-6 x4

Polk GXR-4 x2

Posted By: hex0rz

Date Posted: December 21, 2005 at 3:21 AM

It is obvious that I also 'am trying to obtain cosmetic and security features also... The wires are going to have to come out of that box sometime... My box is double chambered. One brace is in the middle. Although, now that I thought of it, I may just put another in to seperate the subs and leave a slot. Maybe put in an LED light strip? This can also work to my advantage because I made the box a little bigger than specified. ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: December 21, 2005 at 4:28 AM

------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: forbidden

Date Posted: December 21, 2005 at 7:46 PM

I don't really buy into his theory. Fact is I have had subs destroy 4 Xtant amplifiers last year and the amps were not mounted to the box. The box was made so as not to flex as well so I could have mounted the amps to it. So what killed the amps? The acoustic shockwave of the sub rattled the caps right off of the circuit boards. If one can expect a sub to flex a box so much that it is going to warp a heatsink of an amp that a circuit board is attached to, well let's say that I have yet to see such a creation. If the box is flexing so much as to cause sucha vibration to occur, obviousely one would be losing drastic amounts of energy being lost to such vibrations and would brace the box to keep it from happening. If that much abss energy is coming out of the sub in the form of sound, then the energy would still cause a board to flex or other damage to occur even if the amp is in the vicinity of the sub system. Think about it for a minute, if you can feel the bass in your car and watch the mirros shake, it doesn't really matter where your amp is either. End result, I don't buy that theory. ------------- Top Secret, I can tell you but then my wife will kill me.

Posted By: dwarren

Date Posted: December 21, 2005 at 8:51 PM

forbidden wrote:

I don't really buy into his theory. Fact is I have had subs destroy 4 Xtant amplifiers last year and the amps were not mounted to the box. The box was made so as not to flex as well so I could have mounted the amps to it. So what killed the amps? The acoustic shockwave of the sub rattled the caps right off of the circuit boards.

Poorly designed equipment, eh? -------------

Posted By: hex0rz

Date Posted: December 22, 2005 at 1:34 AM

Ahhh a very striking comment, forbidden. The same guy from Car toys told me the same thing. He said he feels it wont matter where the amp is really because no matter where its at, its going to have bass traveling through it. I agree with this, to an extent. The thing is, I feel that there is a distinct line in this. I feel that when you mount something to the box, it is going to feel "amplified" bass. Because it is not transfering through the air and the vehicle. It is transfered to the amp through the wood. This is why I feel that if there is a way to build some sort of structure that would dampen the vibration, you could use the top of the box as an amp rack also. On Friday, I will post up a pic of my sub box that is being made for an amp rack addition... ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: December 22, 2005 at 7:16 AM

There are ways to isolate an amp, to a degree when it's mounted in a sub area, whether it's on the box or off. It's true that an amplifier will take some jolts when it's attached directly to either the enclosure or the chassis of the car. When I installed an amp rack in my car, I used wire shelving as an isolator. The plastic-coated wire is attached to a rack which is bolted to the chassis. The amps are attached to the wire shelf. The wire acts as a damper of vibrations and makes a huge difference in the amount of energy that I can feel when touching the amps.

I also noticed a big difference when I separated the shelves from the enclosure, which is where they were mounted at the start. But then, this isn't a three or four sub system either. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: December 22, 2005 at 2:40 PM

Interesting... That sparks me another idea. Bolt the amplifier to the box, but make it a floater. Get extra nuts and tighten it below the amp so only the bolts are touching the box... I would think that the vibration be greatly reduced since its only the bolts that touch the amp... Whattya think? ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: December 22, 2005 at 4:16 PM

There is still transfer of energy, only it will be through the bolts instead of over the entire body. You would have to determine if there is a noticeable difference by doing and testing, I suspect. But it's a worthy idea for the little effort that would be involved. For one thing, if the bolts are at the corners of the enclosure (its most rigid areas), there would be less energy than at the center of the surface. Another factor is that the bolts themselves can act somewhat as damping devices through their lengths. Something I thought of: use the four bolts at the corners to a plywood platform. The platform is only the size of the footprint of the amp, but it is extended to the four box corners by appendages of the same material. Clever cutting out of one solid piece of wood will keep the platform and "legs" all on one plane. The plywood legs will act as shock absorbers but still be strong enough to support the amp; and plywood is a better choice than MDF for something like this because of its elasticity. Carpet it for a nice look that matches the box. The amp is just bolted through the platform and sits snug against it. Other ideas found if you do some research into isolating techniques used in building home theaters. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: December 22, 2005 at 4:52 PM

Hmmm thats interesting also! Thankfully I have'nt finished my box yet. Because these ideas keep on getting better and better! All I have to finish is the amp rack. This subject is the part thats holding me down from finishing my box. I needed more planning on placement and wiring... Do you think you could make a picture of what your talking about stevdart? Don't quit understand. Sorry. I made a dead space on top of my sub box. Between the box and amp rack. I put braces in between. I can use the braces for bolting points. I'm going to have to use a bolt that is small enough but long enough to mount my amp through 2 1/4 inches of wood. So like, 3 inch bolts to be safe... Tomorrow, I will post up some pics of my box, and give you 1000 words. ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: December 22, 2005 at 9:34 PM

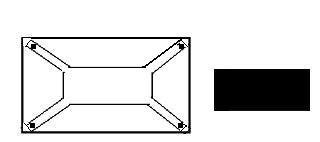

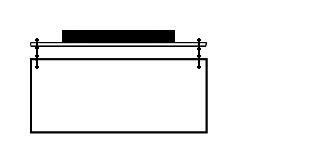

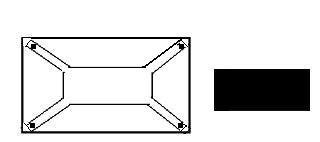

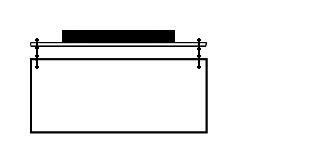

It would look something like this, from the top and the second is a side view:

There would be a bit of sag in the center of the platform under the amp. But that's what this is about. The ride would be Caddy-like for that amp. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: December 23, 2005 at 12:07 AM

Ahh, okay. Then just bolt the amp to that board? Would you think that instead of having those lines of the wood come to them middle piece; just be one complete board instead? I would think the difference would'nt affect the amount of vibration. ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: Paradigm

Date Posted: December 23, 2005 at 1:47 AM

Just put some shock absorbers / springs on that platform, stevdart, and you've got it made  ------------- VEHICLE: 2002 GMC Sonoma ZR2

Alpine CDA-7940

AudioControl EQT x2

JL Audio 1000/1

JL Audio 10W6 (originals) x3

Kicker ZR120

Kicker ZR460

Polk GXR-6 x4

Polk GXR-4 x2

Posted By: hex0rz

Date Posted: December 23, 2005 at 2:15 AM

Just like shock absorbing systems for buildings in earthquake zones.

-------------

Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: December 23, 2005 at 4:19 PM

One thing I just noticed... Even though plexiglass is going over this enclosure, they still can get into it if they somehow got the screws off. The bolts from the sub box to the amp board will have to be thick. I could take a dremel and cut the bolts. Then just take the amp when its still on the board!

-------------

Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: December 31, 2005 at 1:52 AM

Hey guys. Posting back up on this thread instead so I don't have to waste space making a new one. I have finished the box now. I went and picked up more little goodies from Car Toys. I had the chance to get my plexiglass today, but the guy does'nt want to sell it to me until I find out what I'm going to screw it down with. And more issues of whether or not I have a squared box. Then I still have to get the material to upholster my box... I just been working lately, so things are slow. But eh, I just braced the dead space below my amp rack. I'm gonna have some rubber bushings for the amps bolts. I will have more pics up soon. (When completely finished) I took this pic with my camera phone so don't expect exceptional quality...

------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: geepherder

Date Posted: December 31, 2005 at 8:30 AM

Nice work. I don't understand, though- "what I'm going to screw it down with"? Screws, maybe? No, seriously- just drill some holes for your screws and countersink them. A salesman that won't sell- sounds kinda power-hungry, don't you think? Hey, your room looks messy like mine. ------------- My ex once told me I have a perfect face for radio.

Posted By: hex0rz

Date Posted: December 31, 2005 at 2:59 PM

Yes, thank you. It took like 4 days to complete the building process. It made me grow very impatient to the fact I barely could do alot at one time. Haha, and I still face the same problem. Still have to get the rest of the stuff and here I'am, waiting, and waiting, and WAITING! Lol, I'm dying to hear how this is going to thump! The guy wanted to know what screw size I'm going to use so he can drill the holes for me in the plexiglass. He said no normal drill bit is going to get through it. He said to compare it to glass. I make one mistake, and its all over. I sure don't want to throw away $50 for a piece of plexiglass! He is also going to drill it right so I can countersink them. Haha, man, you have no idea. I was on the phone with the guy and he said I had 30 min. to get down to his place or else hes gonna leave. And believe me, it did'nt sound very polite. But I guess thats what happens when you call after 5pm, haha. I got there, and man, it was even worse! He is the type of person I would call raw. I hope he does'nt talk to all his customers like he did to me. I don't think he could exclude one swear word from any sentence without dying. Although, he was very helpful, and I'm glad he did'nt let me purchase the plexi without knowing some things first. Haha, I went to Car Toys after, and the guy I was talking to knew the plexiglass guy. He told me thats how he is. From what he says, the guy works there drunk! Oh ya, I would'nt consider it to be messy. :) Just, cluttered. Haha! ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: December 31, 2005 at 4:01 PM

I sure wish this was a subject of lecture. No, sorry, it is not. It is a subject of trial and error. I could have posted this in my existing thread about my subwoofer box and amp rack design, but I'd prefer an answer ASAP. Much help appreciated! It is something that really is'nt thought about thoroughly because it is also routine. But it has its own category, and a book written about it. Screws! And even people like me who have sat through classes about it, even screw up! I'll cut to the chase though. Its been a while since I have dealt with screws, and so, your mind decides to let you forget since it is'nt very important to it anymore. Well, I was affected by this. I put in an 11/64 drill bit and pre drilled my holes in for my subwoofer. Everything seemed fine until I put the screw in! The screw was the same size as the drill hole. Now from my own reasoning, I think I should have used a smaller bit for the bigger screw. So I put in a bit smaller than the existing one. Drilled new holes, and still to big! The screws go in waaaay to easy. I fear that its so loose, the screws will start backthreading itself and the sub, will fall out. I have a couple of remedies, although. I know the answer to one of them, but unsure about the other. 1. Use a bigger screw than 11/64. (Obvisouly that would solve the problem right there...) But then I wonder. 2. Could I just put silicon over the screws? I would think that would keep them from coming out. And if I wanted to, I could peel it off and take out the screws. I dunno, how big of an issue this is. But hey, I would assume its no laughing matter. Since the fact $500 is too much for 2 subs. You feel me!? ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: December 31, 2005 at 6:34 PM

You're talking about the starter holes for the driver? Just big enough to keep the wood from splitting. The screws have to cut spirals through the MDF as you turn them in, and they have to reach a stopping point where you can exert a lot of torque and can't turn the screw any more. There are no remedies for too large of starter holes, like putting chewing gum or something on the ends of the screws. You could likely remedy a bad install of a tiny driver like a mid with wood filler or sealant, but not a hard-pounding sub. Rotate the sub and start over, or if the logo is c**keyed and doesn't suit you, make a new baffle. A drill bit for a starter hole can be no larger than the diameter of the screw shaft...less threads. It should actually be slightly smaller so that the act of driving in the screw compresses the surrounding wood. The spiral threads of the screw and the compressed wood are what hold the sub in place. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: January 01, 2006 at 12:14 AM

Ya, thats what I'm saying. Ehh, well, I guess I cant have my subs logo straight...

-------------

Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: volcommag

Date Posted: January 03, 2006 at 12:39 AM

how about.....for mounting the amp onto top of subbox, install rubber gromments of some sort between the amp n the box. The rubber should GREATLY dampin the vibration...correct?

Posted By: hex0rz

Date Posted: January 03, 2006 at 12:57 AM

Whats up. That is what I'm doing insetad. But I'm still going to make "it float". As for the box goes, I have got the plexiglass finished. When I go and buy all the screws and whatnot, I'm just going to get bigger screws for my sub so I can have a straight logo. The upholstery shop I go to won't be open till tomorrow. But I got to work... I think I may have it finished this weekend... :\ bummer.... I have the RCA's come out the back and them will route them to the sides of the vehicle. The other wires are going through the middle. The grounding point will be somewhere on the floor pan. I'm trying to build a console , but I need ideas. Check out the fiberglass forum, if you can help! EDIT: Since I need to fuse the fans from the relay, I need to know where I can get the fuses to just above their amperage and something that houses the fuse. Radioshack carry something like that? And I also upgraded the fuse on my power line from the battery! Its a 135 amp circuit breaker! It cost $50 though. He said it will never go out. Everytime its tripped, you reset it. Is'nt that just dandy?! ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: January 03, 2006 at 4:36 PM

T-nuts are an alternative, too, if the screw holes are too big for screws. Some box builders use these right from the start. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: January 03, 2006 at 5:57 PM

Hey, stevdart. I got a question for ya. When you are fitting screws, would'nt you drill a hill one size or two sizes smaller than the screw? That way its a tight fit and threads the wood. Right?

-------------

Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: January 03, 2006 at 11:49 PM

Well, it depends on the wood...hardwood, you drill exactly the diameter of the screw shaft. Softwood and fiberboard, you go just a tad smaller with the bit. I don't know about sizes. I just eyeball them.

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: January 04, 2006 at 1:19 AM

Haha, your amazing... Its MDF! ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: January 10, 2006 at 1:57 AM

Whats up guys. Good news. The enclosure is complete! Well, I dont have the fans installed, and the wiring for the relay to the amps finished and whatnot. The plexiglass looks so freakin' good on top! This thing sure does scream out steal me though. Haha, I gotta tint the windows heavy now with my highly invested alarm system. There is another problem although. I'm not sure whether it really is a big deal. To compensate distance from terminal cups to amp, they are sideways. Problem I found out today is that 1 bolt on each amp cannot be put it. So each only has 3 on them. I could'nt fit the nut on the bolt since the bolt is too close to the port wall and nut is too fat. The only thing I can think of remedying it is use the extra wiring left over after I cut them down, and mount the amps parallel with the box. But, what do I do About the existing holes? I assume I can just put a silicon bead over the hole inside the cabinet? As for the box, Well, if it were'nt black, you would see the horrible upholstery work I did'nt put my effort into. And I was also ill equipped for the job. But my hunting knife seemed to slice through the trunk carpet pretty well. Most of it by the naked eye looks seamless. But a prying eye will spot it out. Oh well, if I decide, I can just pull it all off and re-upholster it. Hey paint it! Ya!!! I will get some high quality pictures up tomorrow hopefully. See you then! ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: hex0rz

Date Posted: January 11, 2006 at 12:01 AM

https://memimage.cardomain.net/member_images/2/web/1370000-1370999/1370897_31_full.jpg https://memimage.cardomain.net/member_images/2/web/1370000-1370999/1370897_32_full.jpg https://memimage.cardomain.net/member_images/2/web/1370000-1370999/1370897_33_full.jpg Here is the pics! I redid the amps and they are now parallel with the box. All 4 points of the amp are bolted. It looks better also, but from these pics, I'm sure you have an idea what I'am doing. Thanks for your help, stevdart! ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: jfunk06

Date Posted: January 11, 2006 at 5:10 PM

Did anybody mention mounting the box to the chasis?? That will significally cut down on box rattle. Otherwise, the best place for an amp, is not in your car! As previously said, if its in your car, its going to rattle, if an amp cant take it, buy a new brand, period.

-------------

Govenor of Jimcinati

93' GMC Safari XT

Posted By: hex0rz

Date Posted: January 11, 2006 at 9:08 PM

Uh huh... *thinking* Well, I think MTX has my back. They are reliable. But we'll see what happens! As for the box to chassis, I'm not sure. I have never heard about it reducing vibration. I just know that if I bolt my box to my chassis, it won't get stolen! Haha! Well, if it cuts down on it, then I guess its just gonna be another bonus to bolting my box in. Before I installed the amps, I thought about it. And to figure, the amp would probably suffer from LESS vibration if it was'nt bolted down. Just let it sit in there, although it would slide on a sharp turn. But I bet thats probably the ultimate killer for vibration transferring to the amp. Who knows... ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

Posted By: stevdart

Date Posted: January 11, 2006 at 10:56 PM

A box that can move is a killer of SPL. The full force of the woofer is diminished (for every action there is an opposite and equal reaction). Rattling isn't the issue as far as bolting the box down goes, as it will still transfer energy into the sheet metal either way: by direct transfer from the box or by the sound waves, and the metal will transfer it back directly. So yes, bolting the box securely is standard procedure.

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: hex0rz

Date Posted: January 13, 2006 at 12:15 AM

Haha, no Stevdart. I was'nt talking about my box. I was talking about my amps being bolted. Unless I'm not catching what your saying? I'm not worried about the box one bit, except its going to be bolted haha. I have some problems that I face although. I need to fing a good location and get a hole through the cab. Freakin' Mazda's and their double wall sheet metal! Do you think 2, 1" round nylon bolts will be good enough? ------------- Vehicle: Mazda B2200 1989 X-Cab

Audio System:

1. (2) MTX TA3401

2. (2) MTX Thunder 7500

3. (1) MTX TA3202

4. Eclipse Fujitsuten SC8264 Component series

5. Pioneer Premier DEH-P770MP

|