so i am getting ready to build a box for a JL 10w7. I have all the specs from the manual for the size etc. But my quesion is, is what cuts should i make? I used to make dado cuts and join the sides like that, but i know longer have access to that equipment. On the jl website, it just looks like the box is cut with a straight blade, and screwed and glued in an L shape (the joints resemble an L as opposed to dado). My question is, is that strong enought? How can i brace the internal box so i don't blow the sides out. I want to make the box as storong as possible with basic saws. (i have a circular, to make the straight cuts, and a jig to make the cut outs)

thanks

btw, i did not know if this was the best place to post this, but i didn't see a sub forum on fabrication, only fiberglass

Straight cuts, butt joints is all that's required. Seal inside seams with RTV or some other sealant. Install cross-braces connecting opposite sides and top-bottom.

-------------

Support the12volt.comwhat do you mean by cross braces?

i have used wood blocks in the corners. Do you mean running a few inch or so high strips along the lenght of the box?

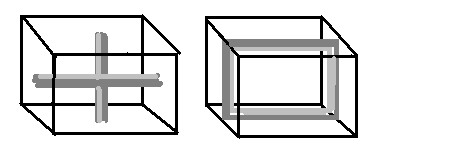

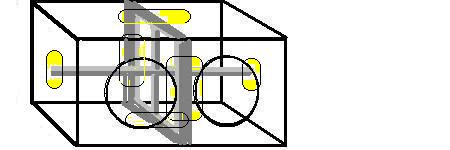

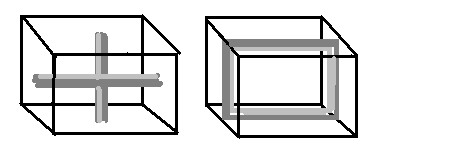

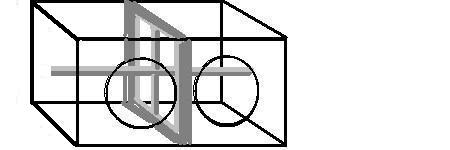

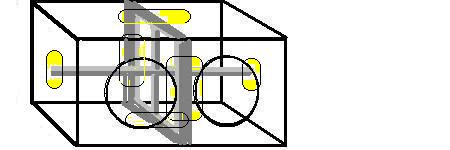

Here are two ways to make cross braces...if you can figure out what I intended to draw. The first is cut MDF that connects to the outside walls near the centers of the baffle expanses. 2 X 2 construction lumber will work as well. The second pic shows a full baffle cut to the dimensions of the front and rear baffles, and the inside is cut out. It, too, is centered as much as possible from all four corners on every side. This also gives great structural integrity to the enclosure. The design in the first pic will normally take up less displacement if size is a big issue, and smart use of scrap pieces and the use of a good glue will save on material costs over the second design.

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

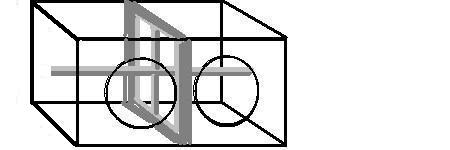

A large box might use a combination of brace types:

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

So, why not just put in corner braces? The corners of a box are the strongest, least likely to flex parts of the box. No need for bracing there. The 90 degree joints that run along the lengths ore the next strongest. The weakest points are the centers of the baffle panels. If a great amount of pressure allows them to move, even to an impercetible level, it will be detrimental to the output. It would make the sound weaker.

With rigid lengths of wood spanning the box from one weak point to the opposite weak point, the structural integrity of the box becomes the eqivalent of two, four or more structures. The two braces here effectively create much smaller areas of baffle expanse, so the amount of pressure would have to be much greater now to cause flexing in this box. And the braces are, of course, securely fastened to those baffles.

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

This kind of info should be integrated into the What is a proper sub box thread. Refine it and post it to the thread please Stevdart. If you really want to ensure that the sides of the box have a good seal and will not blow apart at the seam, add a good layer of fibreglass on the inside edges of the box.

-------------

Top Secret, I can tell you but then my wife will kill me.