I have a 2003 f150 an am also looking at smoothing out my bed rail caps. i know i need to make some molds for this, but am unsure about doing so. i know i can build plywood boxes larger than the factory plastic caps and lay the caps in, but raised off the bottom. can i use spray foam and then cover with tin foil and wax(or any release agent) and then lay em up? all input would be great at this time. also how could i go about fastening them to the bed rails? let me know

-------------

Make it Euro'n!!!

I am not shure I follow what you are thinking...the bed rails, as in the top side of the bed? Maybe post a pic of what you re talking about, because I thought the ones on that truck were pretty smoothe to begin with

-------------

used to be loud, used to be fast...now I am married LOL

ibasspro wrote:

I am not shure I follow what you are thinking...the bed rails, as in the top side of the bed? Maybe post a pic of what you re talking about, because I thought the ones on that truck were pretty smoothe to begin with

Hi, street scene makes em heres a link, mine are plastic and gray. i have a tonneau cover and i still want to smooth them out https://www.streetsceneeq.com/product_list.asp?makeid=6&modelid=35&year_id=2003&mi=2&x=14&y=9

let me know if you got any input please.

thanks

-------------

Make it Euro'n!!!

There are all sorts problems that you will encounter on a project like that if you do not physically mold your part from the truck itís self. I strongly advise against any attempt to use wood, foam, or any forming system that can change shape due to temperature or humidity. I have a method that I use to make exact duplicate parts that might help you get a perfect mold of your bed rails. After you have that you can shape the top side (the part you see) any way you want and it will be a perfect fit to your truck.

You will need several products that you do not likely have.

Polyease www.tapplastics

Vette Panel Adhesive/Filler www.evercoat.com

Vinyl-ester resin www.tapplastics.com

Double sided foam tape

Small spiral roller www.tapplastics.com

And some products that you probably already have.

Polyester resin

1.5 oz. fiberglass matt

Small brushes

Masking tape

The process goes like this. I make a fiberglass mould by glassing rite over the part I want to duplicate. Forming a negative. Then I peal that off and lay glass inside that negative forming an exact duplicate of the original.

For your part all you need is that negative and then you can build on top of that.

In my example I needed to replicate the chrome rail that runs along the top of a 57 Chevy door panel. After I had my replica I was free to modify its shape with out damaging the very valuable original part.

Step one

Here is the original part. Notice that I have used double sided tape to outline where the mold edges are. This helps me demold my part as well as give me a visual line to grind to after I demould my part.

Step two

Spray the part down with polyease (release agent)

Next I mix the Vette filler with standard polyester resin. 4 parts filler one part resin and mix in only cream hardener no liquid MEKP. And brush on the mix.

Step three

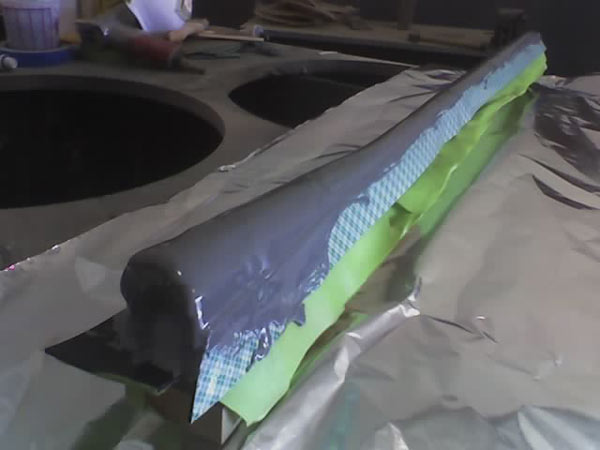

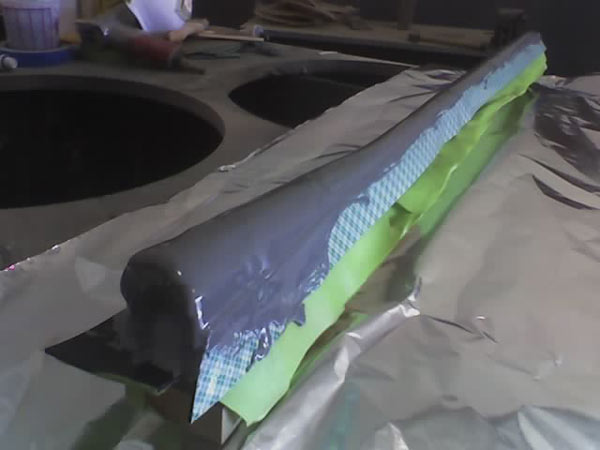

Using Vinyl-ester resin apply 2-3 layers of fiberglass matt. No sanding required. Use a small roller to thoroughly saturate the matt. While still wet I suggest that you lay down some angle iron and let it bond. This will keep your negative from warping. With a long piece simple gravity will warp your part once off of the truck if its not reinforced. Angle iron is cheap and readily available.

Step four

Pull your negative from the positive (your truck). Use compressed air for this. If you get just a little air between your parts they pop rite apart. As you see in the pic I now have a perfect negative. No warping, no cracking, no pin holes, no sanding required. Denatured alcohol works well do degrease all parts. At this point If I were you I would shape the top surface of your new panel using the vette filler as your bondo. Prime, and paint.

[/IMG]

[/IMG]

[/IMG]

The remaining steps on my project

Now that I have this flawless negative I respray with polyease and paint more vette filler/resin mix into the inside. Then fiberglass matt. When I pull my part all I have to do is degrease, prime and paint. No body work!

This is the black part at the top of this door panel.

Warning

Standard body fillers and polyester resins will not work in lieu of the products that I have suggested here. They are unstable when exposed to heat, moister, and display to high of a shrink rate for this type of project.

wow thanks speakermakers,

that was probably the easiest most informative input i could have ever recieved. you must really know ur stuff. i havent heard of alot of those materials, are there possibly generic names for them i might brodden my search with, thanks again.

-------------

Make it Euro'n!!!

Unfortunately no. I have spent an extreme amount of time with R&D on this process and thousands of dollars wasted on materials that did not work before I had it down to the science that it is. So I am afraid that can only recommend the mentioned brands. You can get all of the items @ www.tapplastics.com and your local auto body paint store.

The vette filler is a specialty filler thatís intended for use over fiberglass body panels on high end sports cars. They have formulated this stuff to apply and sand just like regular bondo but it shrinks closer to 1% when curing rather than 7-9% like standard fillers.

The vinyl-ester is very much like regular polyester resin (same hardener, mix ratio, working time, etc) but wets the fiberglass much better, is 3 times the strength, is much more flexible when cured, makes a better physical bond to the filler, and is much more moister resistant.

The Polyease release agent will not let anything stick. You donít want to risk not being able to demold your part!

I have to wonder though wouldnít it be easier to purchase or maybe modify some existing parts? Not that I donít understand the satisfaction of enjoying a custom made part.