Ok I'm working on putting a carputer in my 2006 Colorado Crew Cab and have decided to put the screen in a custom center console just under the climate controls in the front of the truck I am probably going to use a 10 inch Xenarc screen and what i want to do is to make a housing for it so that with the push of a button the screen can hide away under a panel that looks as thought it is just part of the console, and when you hit said button a second time the screen flips (spins really) and reveals itself.

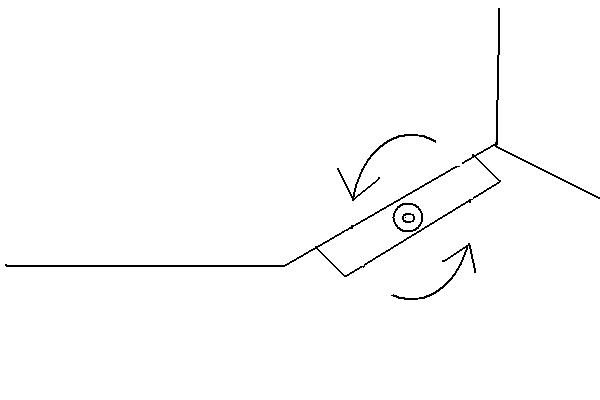

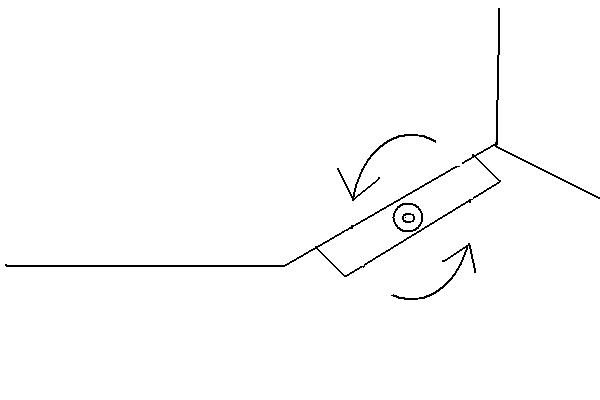

I know this is a very cheesy paint diagram but I hope it helps convey my point, the circle is the pivot point, this view would be as if you were looking at it from the passenger side.

Any Help would be greatly appreciated

Hi there! I have a design to help you out... It is a bit rough but fairly flexible design. There are a coupld of rules for this design, but nothing excessive.

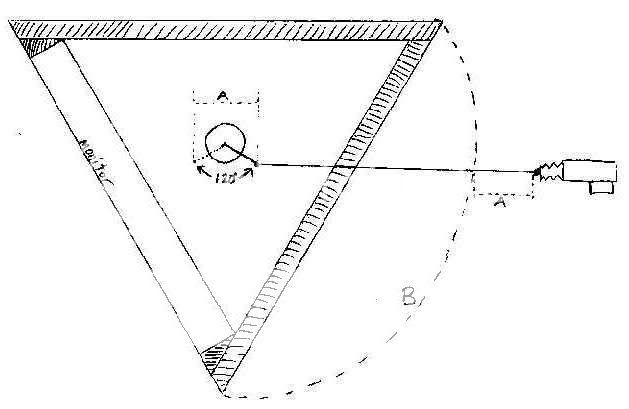

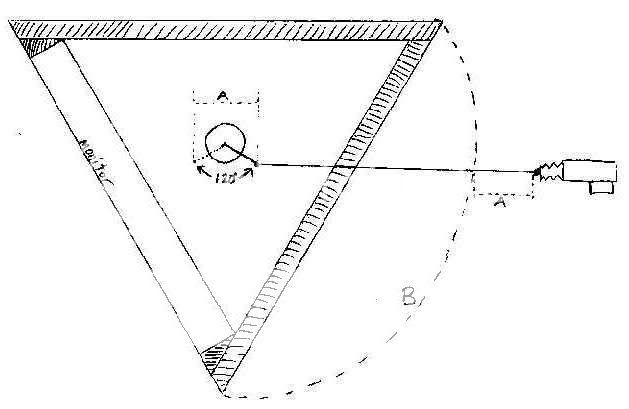

A: These distances are the travel distance (stroke) of the actuator. You can find many actuators with 3/4" stroke typically but you can find some with 1" strokes out there for relatively cheap. The key to making this design work is at the pivot point where you'll have an arm on the axle. For 120 degrees(*) the point to point distance must be the stroke length. For 1" stroke, the arm will be 1/2" from center point. Doesn't sound like much but this isn't a really heavy part so the weight should not be an issue.

B: This arc is the point rotation area. the actuator should not be within this area so the rotational assembly will not get in the way.

So why I used a triangle setup (for those who are a bit weak in the geometry area, 60 degree angles) . Triangles will allow the display to have a much smaller gap versus a thin rectangle even. I recommend using 1/4" mdf or 1/8" hardboard for the structure. Your cutout will have to be a bit larger, but the result will have thinner gaps for a cleaner look. Another advantage vs using a flatter design is that you will only need to worry about 120* swing instead of 180*.

So here is the diagram. You'll have to forgive the poor scanning... I did the image by hand and was too lazy to do it on the comp.

If you have any more questions, please do not hesitate to ask.

Ganbatte ne!

-------------

Never send your ducks to eagle school.

The difference between ordinary and extraordinary is that little extra.

The 3Ls of life: Learn from the Past, Live for the Present, Look to the Future.