I was wonderimg if there was some kind of trick to stapling the mold cloth to a door panel when preping it for glass. I find that the staples don't always penetrate the plastic or the plastic shatters. Is there a certain type of staple or staple gun to use? Any other suggestions?

i like to use hot glue too because when the mold is strong enough u can somtimes pull it off,trim it, and fiberglass it on

-------------

dream it, build it, fiberglass it

try carpenters glue that always works for me or like mentioned earlier whip out the hot glue gun best of luck

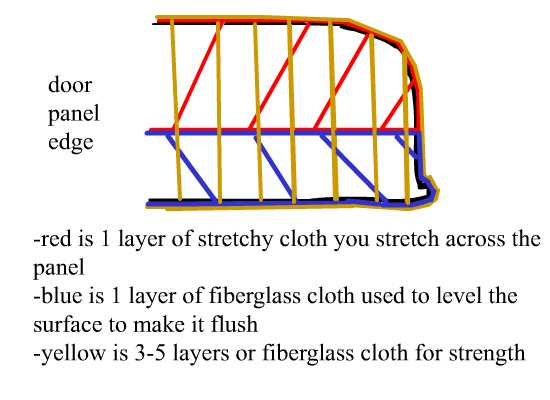

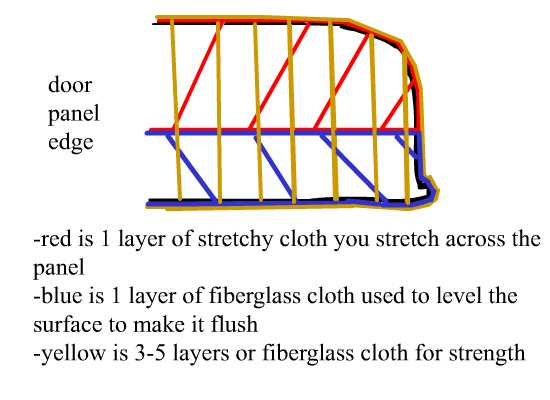

i use hot glue sometimes, but i recently worked on my door panels i stretched a fabric over the entire thing and used these clips that i got at staples (enough for the entire door cost 4-5 dollars.) then you can reuse them for the other door when the resin dries. I tried using weights to ancor it down on all sides, but it seemed impractical when the edges of the fabric did not meet the edges of the door to well. heres a pic -justin

to pjon how do you expect to remove those clips after your resin cures? this aint a diss but an actuall question

ok, well what the clips do is hold the stretchy cloth over the plastic panel, if you look at the first picture, you can see that the cloth is being held tight against the plastic all the way to the clips on the bottom, this allows the the resin'd cloth to bold well to the plastic creating a good base for the fiberglass cloth. however, you do not need to put resin on the cloth all the way to the clips, infact it is not a good idea. If you paint it about half way down, that will be good enough to hold that layer in place ( the red layer in the pictures).

step 1

Once you have attached the stretchy cloth to the panel with the clips, you take a marker and draw a line around the panel running parrallel at about half way up the sides of the panel as you can see in the first picture (line in black). Once you saturate the stretchy cloth ABOVE THE BLACK LINE with resin with a paint brush or something, (thats what i use) you let that cure, and take a dremal tool or small cutter/grinder wheel and cut through the cloth on that line all the way around the panel. then once the cloth under that line is seperated from the top cloth, you just remove the clips, and pull that cloth off. If you want, you can put masking tape over the clips so they stay clean and they come off easy. If there is alittle resin on the cloth below the black line, just pull hard and it will still come off, but make sure you cut all the way through that black line all the way around before you try to pull it off just to make sure you dont accidently pull off the fiberglassed cloth above the line.

step 2

once that is done, and the bare plastic below that black line is exposed, then you simply take real fiberglass cloth strips hold them in place below that line and paint resin on to them . (the blue area in the second picture) do only 1or 2 layer of this over all the exposed plastic all the way around the panel depending how thick the stretchy cloth was so they look and feel level .

step 3

once this is done, the entire panel should be covered with resin'd stretchy cloth on the top and top half of the sides and fiberglass cloth on the bottom half of the sides beneith that black line. After the resin has harded and cured, then you grind the high points if any of the fiberglass cloth, and then simply apply fiberglass matt over the entire panel, sides, top and all. Heres a tip, build a little holder out of wood to hold the panel vertical so you can apply fiberglass to the edges of the blottom of the panel. And try to wrap the fiberglass cloth around to the back, adn do so with out any air bubbles, this is important on the edges cause its harder to fill in little holes on the edge once you sand it. after each layer hardens try to sand or grind down parts of the hardened cloth that may stick out so the next layer remains smoth. once you have 3-5 layers down, grind the top layer so it is not as rough, then sand it alittle with 100 mediem sand paper, (the redish paper at home depot works good) it does not have to be sanded perfectly, then apply some good body filler like you apply peanutbutter to bread for a sandwitch. ( i dont know use your imagination) anyway, then sand with 100 then 150 and so on till its real smoth, and then what ever else you want to do. i know how to fiberglass doorpanels, thats all i have done so far. but i know what works and what doesn;t work. I know how to come up with short cuts and the clips is one of them. -justin

by the way, this is if you want to glass the whole door, if not then you can oviously draw a black line on the stretchy cloth around the area you want to glass, then simply glass that area. -justin

heres the back of the driver side panel:

I use spray adhesive(3M workes best for me). Sprey down the adhesive lightly, cover with tinfoil, spray adhesive the cloth and resin the cloth. after it cures the whole thing will peel off and a quiek wipe will clean the origional door of adhesive(just in case it was just to get the mold)

I like to make my own door skins with 1/8" hardboard than design from there?