more pics!

Printed From: the12volt.com

Forum Name: Fiberglass, Fabrication, and Interiors

Forum Discription: Fiberglass Kick Panels, Subwoofer Enclosures, Plexiglas, Fabrics, Materials, Finishes, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=48895

Printed Date: January 15, 2026 at 12:26 AM

Topic: more pics!

Posted By: doc t

Subject: more pics!

Date Posted: January 29, 2005 at 6:46 PM

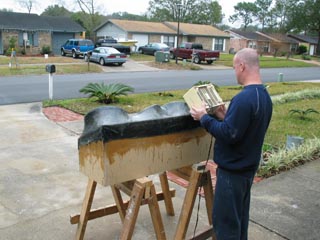

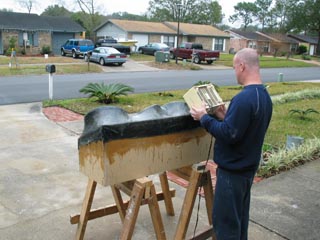

as promised...but first here's a recap. 1-22-05 temp was 32deg and we started . 1-22-05 the fleece streched.

1-22-05 even with it in the sun it took 3hrs to harden......could be we messed up on the resin/MEKP mix? NAH!!!

1-29-05 this weekend it was a little warmer we removed the bottom and layed 3 layers of glass inside.

1-29-05 yes it was warmer but we had to help it a little....I put my son on heater duty!

1-29-05 it only took about an hour to set up then we flipped and started to prep the outside for glass.....that fun starts tomorrow.

if all gose right and murphy doesn't come around, I think we can start the bondo! yippie! it's pretty strong with just the three interior layers....6 total should be real strong...or should i add more? -------------

All Bleeding stops.....eventually!

Replies:

Posted By: soundzplus

Date Posted: January 29, 2005 at 6:59 PM

May I suggest .... Use RageGold Xtreme for the outside .. Way easier to sand .. gives a nicer finish .. Spray on a Filler / Primer for the small "holes".. then its off to Reg Primer and some final sanding .. Good Luk .. lookin good ..

Posted By: jt73

Date Posted: January 30, 2005 at 9:43 AM

lookin good

Posted By: jt73

Date Posted: January 30, 2005 at 9:46 AM

what type of vehicle is this going into again? very nice...I would like to do subs in the bed of my truck and your box reminds me of other truck bed type sub boxes

Posted By: doc t

Date Posted: January 30, 2005 at 11:56 AM

'96 ford ranger....downloading pics now...will have them up in a few.

-------------

All Bleeding stops.....eventually!

Posted By: doc t

Date Posted: January 30, 2005 at 1:37 PM

he wants the outside covered with suede, so a couple of skim coats of bondo should be enough to give it a smooth finish for that. 1-30-05 after the three layers were applied this morning we helped it dry somemore.

1-30-05 I even got in the act!

1-30-05 after about an hour we started to sand it down.

1-30-05 and this is the truck....he's getting some body work done before its painted. it used to be a candy red, he wants a medium blue with metal flake added.

the box dosent flex at all with the six lyaers on it. each sub will get about 185wrms, I'm hoping that it will hold up to that pressure, any thoughts? we had to stop for today, had to go to work. I think we should be able to finish up next weekend. where can i get that ragegold? any place other than online? how thick can the bondo be and still be effective, there is a 1/8 to a 1/4 inch gap where the sub sits. it's only on one side, i was planning on building it up so the subs sit flush and gets a compleete seal. -------------

All Bleeding stops.....eventually!

Posted By: soundzplus

Date Posted: January 30, 2005 at 2:16 PM

You can get the Rage Gold Xtreme at most Body Shop supply stores - check with them ... Good Luk

Posted By: djdaveoc

Date Posted: January 31, 2005 at 5:43 AM

Posted By: realitycheck

Date Posted: January 31, 2005 at 7:43 AM

Yeah man looking real nice that should turn out awesome.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: realitycheck

Date Posted: January 31, 2005 at 7:45 AM

If you have to build up a section I for the sub to mount too, I would build it out of fiberglass. Or you should be able to take the fiberglass dust if you can get enough out of the box or something mix it w/ resin and it will become like a putty and you build up w/ that. If you dont have enough dust you can add talc powder to it and do the same thing.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: DukeDuke

Date Posted: January 31, 2005 at 9:37 AM

As well, you can use saw dust if you have some of that... it is a nice cheap way of getting kitty hair... or walmat sales Bondo Jelly, which would work as well, correct guys?

-------------

Duke Duke

Posted By: HottAccord

Date Posted: January 31, 2005 at 12:47 PM

Wow, looks REALLY good. One question though, why didn't you trim off the excess fleece that hangs over the side of the box?  ------------- Im a fiberglass whore!!

Posted By: realitycheck

Date Posted: January 31, 2005 at 12:52 PM

Whats up hottAccord I havent seen you here in a while! I dont think they did but they are wrapping the thing in suede anyway.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: doc t

Date Posted: February 01, 2005 at 5:30 AM

it hangs over the edge about 4in all around. wasn't sure if it was too much or not so i'll have to make it work.

-------------

All Bleeding stops.....eventually!

Posted By: 4doormadness

Date Posted: February 02, 2005 at 6:34 PM

very nice looking work so far..keep it up and updated w/ pics.

Posted By: doc t

Date Posted: February 03, 2005 at 6:15 AM

There are minor repairs (need to level out the speaker rings so the subs sit flush) i may take pics of that. When we start to cover it with the fabric and get the speakers mounted....basicly the final steps will be posted. With the superbowl in town this weekend my son wants to go downtown and rub elbows with the eliete of society, haha!, we probably wont get much done on the box. GO EAGLES!! -------------

All Bleeding stops.....eventually!

Posted By: realitycheck

Date Posted: February 03, 2005 at 8:49 AM

Yeah you guys should be able to get out and about no problems! No traffic or anything right, hehe. Cool man I'm really looking forward to seeing it covered in suede and how it turns out!

-------------

Learning the trade one fiberglass creation at a time!

Posted By: raysilvo

Date Posted: February 03, 2005 at 10:17 AM

One reason why you may have a gap in the speaker seat is the fiberglass not laying down completely flat or was not rolled out with a roller.Also from my experience you could of also just did your buildup on the inside of the box and bondo and high build the outer shell.

-------------

ray silvo

Posted By: doc t

Date Posted: February 03, 2005 at 11:11 AM

the city closed off some streets downtown for the NFL Experience festivities....this is one headache i really don't need....i'm a diehard Raiders fan at heart, if they had made it too the big show i would have waided through a mile of s^*$ to see them in the game. there are rumors of some pretty funky parties going on in the next couple of days...the type of parties that would make a grown man cry and get Navy Pilots in serious trouble. every time we tried to get the fleece to stick to the ring in the groove it stuck to my fingers and pulled up...i think what i'll try is to cut out rings from hard board the same size as the box rings, glue them in place with liquid nails then cover and fill the gaps with a glass resin mix, then bondo a clean finish. then hopefully the speakers will sit flush with no air leaks. -------------

All Bleeding stops.....eventually!

Posted By: Teamrf

Date Posted: February 03, 2005 at 6:13 PM

Looking good...  ------------- ~The Rookie~

Rookie of the year that is...

Don't let the smoke out of your equiptment..it doesn't go back in.

Posted By: doc t

Date Posted: February 06, 2005 at 7:06 PM

2-5-05 this is what i was talking about...I totalt skiped over the post about the saw dust and resin, I cut some rings out of hard board and used liquid nails to secure it to the box. then mixed up some resin and coated the ring in side and out. once it hardened, we had to let it dry completly over night to let the liquid nails dry.

2-6-05 this morning it was dry enough to start the bondo.

2-6-05 here you can see the hard board rings .

2-6-05 sanding!

this week I will be filling the some of the small holes/gaps in the bondo so next weekend we can cover it with the suede and then we wait for the subs. and yes it is a lot of bondo especially were the fleece ends on the sides. Burned up my palm sander, so i had to buy another to keep up the progress and not sand too much by hand. getting really excited to be close to having this one done! -------------

All Bleeding stops.....eventually!

Posted By: realitycheck

Date Posted: February 07, 2005 at 8:19 AM

Really Good idea there doc, when I read your post about a gap, I thought you just had a little gap, like a 1/2" long or something. Now I see what youre talking about with that pic of the sub. Good thing you didnt use our idea! I'm glad you got it fixed though and it looks really good.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: doc t

Date Posted: February 07, 2005 at 10:26 AM

I think the saw dust would have worked and was a great sugestion, I got real worried that the liguid nails wasn't going to dry and i would have to scrape it off and start over...hind sight is 20/20 and i probally should have let it dry before laying on the resin,but all worked out fine....just goes to show that attention to detail is paramount. I will post more detailed pics as we start to cover the box...are there any sugestions on how to cover it with the suede? I plan on starting at the top using 3m spray adhesive (90 can) then streatching over the box finishing and securing with staples to the bottom. using a new paint rolloer or the roller i used to put on my dynamat in my van.

-------------

All Bleeding stops.....eventually!

Posted By: realitycheck

Date Posted: February 07, 2005 at 10:41 AM

The only thing I can think of is make sure you spray both the box and the material with glue.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: doc t

Date Posted: February 07, 2005 at 10:58 AM

my only concern is that the glue will bleed through the cloth.....i gues i won't put it on too thick.

-------------

All Bleeding stops.....eventually!

Posted By: realitycheck

Date Posted: February 07, 2005 at 11:05 AM

Yeah is the back on the suede pretty thick?? I carpeted a cover I built for my dad this weekend and I got to much glue on there and it went through of course we were using black fleece to do it with, because it looks identical to the carpet thats in his trunk. Anyway it went through and I dont know how to fix it.

-------------

Learning the trade one fiberglass creation at a time!

Posted By: doc t

Date Posted: February 10, 2005 at 6:27 PM

the final post to this thread will be this weekend with the finished box im my sons truck, so I'll have a lot of pictures for you all. got all the sanding done tonight (THANK GOD!!) looks and feels really good (no, i don't have a box fetish.....at least not this kind of box!!) thanks again in advance for all you assistance throughout this endevor, my next project will be a center console for my "Bat mobile" thats what i call my minivan, sounds better than "I drive a mini van" so tune in this sunday for the pics, same bat time, same bat channel.  -------------

All Bleeding stops.....eventually!

Posted By: HottAccord

Date Posted: February 10, 2005 at 7:23 PM

Ahh the progress looks really good!

-------------

Im a fiberglass whore!!

Posted By: doc t

Date Posted: February 13, 2005 at 10:35 AM

O.K. as promised the grand finally. I nust say that covering it in cloth was a through pain in the ass!

the settings on the camera got changed and i did not relize it till it was too late. 2-12-05 we started with the top and worked our way around the box from top to bottom

2-12-05 it finished up pretty good the sides have a tiny area that the sued did not stretch to cover. the flat areas and curves covered really well and come out perfect.

2-12-05 once we got the sued cut and glued to the inside of the rings, we mounted the subs!!!

2-12-05 wired them in series and parallel and made it look good.

2-12-05 then in they went.

2-12-05 he's sooooo happy.

it's loud as crap, does anybody know where i can get auto glass real cheap! this thing moves mucho air. as a weekend project it took us about 4 weekends and was well worth it! to all who helped with advice and answers to our questions........THANK YOU ALL SOOOOOOOO MUCH. will keep you all updated with future projects that we take on. thanks again T -------------

All Bleeding stops.....eventually!

Posted By: doc t

Date Posted: February 13, 2005 at 10:38 AM

WHOOO! here are the two that did not show too well

-------------

All Bleeding stops.....eventually!

Posted By: 1hot944

Date Posted: February 28, 2005 at 9:44 PM

Nice job!!

-------------

In a world full of copycats, it's great to be an original!

|

Plan, Research, Do

Plan, Research, Do