First time fiberglass enclosure

Printed From: the12volt.com

Forum Name: Fiberglass, Fabrication, and Interiors

Forum Discription: Fiberglass Kick Panels, Subwoofer Enclosures, Plexiglas, Fabrics, Materials, Finishes, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=53564

Printed Date: February 13, 2026 at 3:32 PM

Topic: First time fiberglass enclosure

Posted By: j68rh

Subject: First time fiberglass enclosure

Date Posted: April 08, 2005 at 7:36 PM

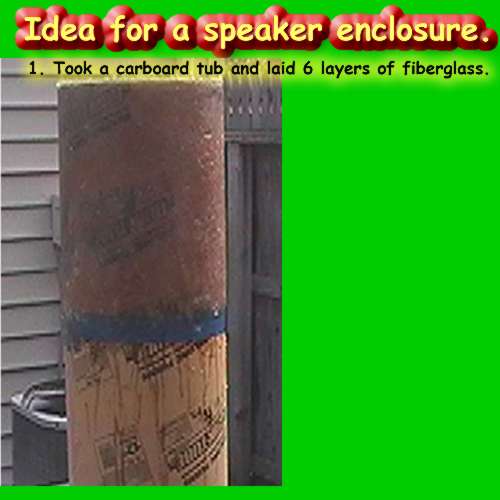

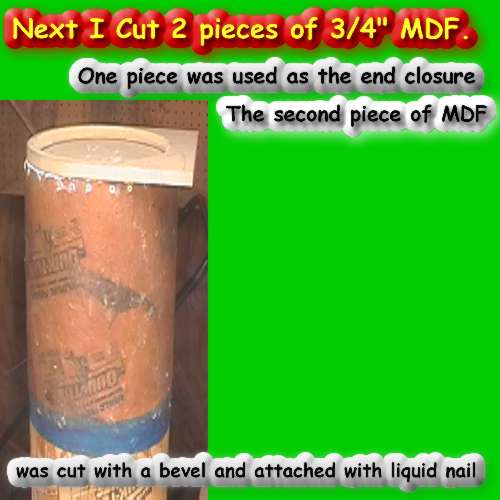

Here is my first fiberglass enclosure. Its almost done but here is start to finish.

Replies:

Posted By: j68rh

Date Posted: April 08, 2005 at 7:41 PM

Sorry here are the rest of the pics!!!!

Well I don't think its not bad for the first attempt at doing a fiberglass enclosure. I am up for some tips for my next one I do. Thanks

Posted By: Drocay

Date Posted: April 09, 2005 at 2:24 AM

not bad, but wut size is that tube and wuts it for?

Posted By: j68rh

Date Posted: April 09, 2005 at 7:11 AM

the tube is 12.5" in diameter and 11" in length. I decide to do a tube enclosure instead of anything else. I used the tube as part of the enclosure to get me the perfect cylinder size with out it colapsein. Its pretty strong.

Posted By: j68rh

Date Posted: April 10, 2005 at 10:08 AM

I'm getting fustrated I am sanding and sanding and i am having a hard time getting rid of the imperfections. what can i do to fix the little imperfections I have used body filler. What else can i do, just keep sanding?

Posted By: Rick_h

Date Posted: April 10, 2005 at 11:33 AM

What kind of imperfections? Pin holes, dips, low spots what?

Pin holes, coat the surface with glazing putty, real real thin coat. Got any pics?

Rick H...

Posted By: j68rh

Date Posted: April 10, 2005 at 1:24 PM

I have a couple of pin holes couple of dips and low spots. the only thing I can think of that is causing the low spots and dips is from the card board tube when I glassed it. The only pics I have right now are the ones above.

Posted By: Rick_h

Date Posted: April 10, 2005 at 1:38 PM

Keep filling the lows and sanding the highs! The least fun part about making FB sutff!

If you are using Walmart bondo, do yourself a favor and get some good stuff, like rage gold or half time. They do not bubble and pin hole and sand like a dream. A gallon of rage is about 28 bucks retail at autobody supply house.

As for the pin holes, you gotta get some spot glazing. It is ready mixed and ready to use right out of the tube. Do not get too big of a tube unless you know you can use it up and put it on THIN.

Try to use someting flat to sand with, keep from cutting finger dents in it. With your project being round, you need a roll of emery cloth in 60 and 120 grit. It aint cheap but last forever. Tear you off a long peice and "shoe shine" your tube. That way you can avoid the finger dents.

Sand and fill sand and fill sand and fill...........

Thats what is all about!

Rick H...

Posted By: Rick_h

Date Posted: April 10, 2005 at 1:41 PM

Oh yea, after you apply a cost of putty and it is ready to sand, break the surface first with some cheap sand paper. It will sand better and won't clog your good paper. Rick H...

Posted By: j68rh

Date Posted: April 10, 2005 at 1:54 PM

Thanks. Yeah i am just using regular bondo from like autozone. I just had an Idea and wanted to try it. my next ones I am going to take your advice and get the better stuff. Its just that I am new to VA Beach so I am still learning the area to get the right stuff. Your oppionion though how does it look?

Posted By: oonikfraleyoo

Date Posted: April 10, 2005 at 2:25 PM

Thats a pretty odd design. I like it though. It would also look great in a HT setup. Where did you find that tube? Is it one of those used for pouring concrete columes? Like Rick said, just keep sanding, and when in doubt, sand some more. If your planning on making more, look into getting a DA, it will speed the process up a lot. ------------- Nik

Jeeputer Progress

[|||||||||||-] 90%

Check it out.

Posted By: auex

Date Posted: April 10, 2005 at 2:57 PM

That is actually kind of old school. But yeah, have fun sanding and sanding and sanding...

-------------

Certified Security Specialist

Always check info with a digital multimeter.

I promise to be good.

Tell Darwin I sent you.

I've been sick lately, sorry I won't be on much.

Posted By: Rick_h

Date Posted: April 10, 2005 at 3:32 PM

As for how it looks, your asking the wrong person in me. The stock radio is good enough for me! :)

I am into gauge pods and monitor installs.....

What your working on is a grat2 place to start as for learning. I am lucky that even though I just started fiberglassing these types of projects, I have done plenty of body work on customs so the "body" skills are there.

Just gotta get used to the FG smell!

Once you are satisfied with your subsurface and get it in primer, it will take on a whole new look. Even after you prime you can use the spot glazing putty if you find a pin hole or sand scratches. Which leads to a whole nother discussion on sand scratch swelling. Gotta get the subsurface as smooth as possible.

Rough shape with 60 grit or file.

Then 80 grit

then 120 or 180

then 220 wet

then 320 wet

then prime

then 320 wet

then 400 wet

then 600 wet

then top coat

then light 1000 wet

then buff with med cut

then buff with swirl mark remover

then hand polish.

Dang is it really worth all this work! :)

Rick H...

Posted By: j68rh

Date Posted: April 10, 2005 at 3:53 PM

it is alot of work but I worked on it all day today and its finally getting there. I just primered it and found a couple very small pin wholes that I didn't see before. I am hoping to finish it this week. Its just kinda hard when you are very busy with your primary job in the Navy and haveing a kid to look after while moms working. Its all good though I am not in any rush

Posted By: j68rh

Date Posted: June 04, 2005 at 3:03 PM

I am working on some other projects like a box for a scion and I am going to be working on a big project more to come on that one.

|