Fiberglass Enclosure with a Wire Frame?

Printed From: the12volt.com

Forum Name: Fiberglass, Fabrication, and Interiors

Forum Discription: Fiberglass Kick Panels, Subwoofer Enclosures, Plexiglas, Fabrics, Materials, Finishes, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=88268

Printed Date: March 04, 2026 at 8:06 AM

Topic: Fiberglass Enclosure with a Wire Frame?

Posted By: jrdakota25

Subject: Fiberglass Enclosure with a Wire Frame?

Date Posted: January 03, 2007 at 8:42 AM

Has anyone made a fiberglass console or enclosure using a wire frame such as chicken wire or something to that extent...im not using fleece im just laying the wire with fiberglass matting...

-------------

If at first you dont succeed then sky diving isn't for you.

Replies:

Posted By: Velocity Motors

Date Posted: January 03, 2007 at 8:48 AM

It's too porous and will not hold up to the weight of fiberglass resin & matting. Not to mention that the holes will allow the matting to sag in those spots causing you more work in the end.

-------------

Jeff

Velocity Custom Home Theater

Mobile Audio/Video Specialist

Morden, Manitoba CANADA

Posted By: maglin

Date Posted: January 03, 2007 at 9:10 AM

could you stretch fleece over it? i have a very limited space for my dash redesign, and was going to make a wire snapsnot of the existing profile of the beast, and fill it in from there. was going to fleece and hot glue to the wire frame

the frame was going to be copper wire with solder points and braces so it holds its shape despite having fleece stretched onto it...

Posted By: jrdakota25

Date Posted: January 03, 2007 at 9:30 AM

well i have my first layer of fiberglass over the top area.. i desided to start from the top and work my way down, I also have several braces inside the console to give it strength...now the issue with the fiberglass sagging i havent seen that yet i have my first coat of glass over it and its actually holding up better then expected...i figured if i build the glass up evenly around the wire then strength wont be an issue... once i get a few layers on ill post some pics...

-------------

If at first you dont succeed then sky diving isn't for you.

Posted By: jrdakota25

Date Posted: January 03, 2007 at 10:09 AM

Ok, if im using wood as a skeleton how thin can the wood be? as long as the board isnt flexing i should be ok correct?

-------------

If at first you dont succeed then sky diving isn't for you.

Posted By: jrdakota25

Date Posted: January 03, 2007 at 10:18 AM

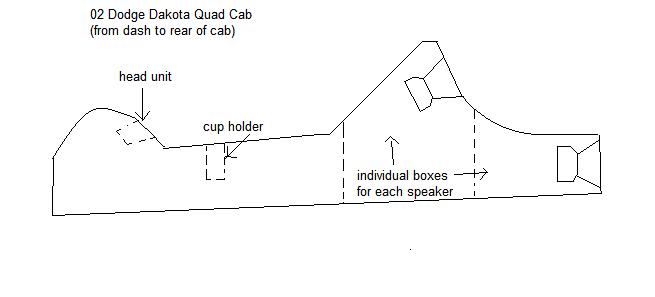

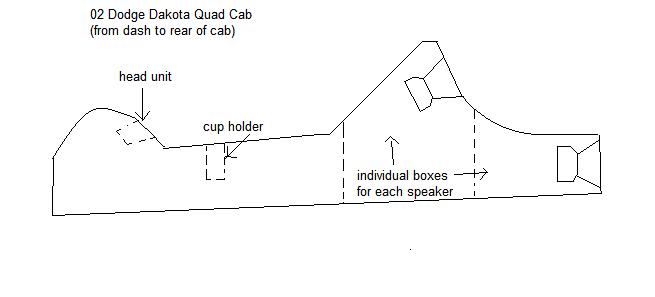

well since im not to far into the first console with the wire frame ive done some thinking... and im probobly not going to waist my time with the wire is there anyone that can give me the best way to build this to house 2 jl 10w7's...help me out guys  ------------- If at first you dont succeed then sky diving isn't for you.

Posted By: bigste925

Date Posted: January 04, 2007 at 8:01 PM

that is gonna be one huge console my man. Housing one w7 i could see but 2 in that small space is going to be rather hard for you to do. you need about 1.5 cubic ft for each speaker. Im not sure how much room you have in the back of the cab but the box would have to flare into the area where people put there feet.

Posted By: ricoshay

Date Posted: January 05, 2007 at 8:10 AM

i agree with big...if u haven't bought the subs yet, get some w1's or w'3s. But if you are really wanting to then do the damn thang!. Make a mold over the transmission hump first. Make the sides out of mdf. Mount your rings where you want them and then place boards in the frame to separate chambers. Then you can staple you cloth to the dividers or just resin/glass the hell out of the cornes where the dividers meet the frame. The cup holder can be done by wrapping a cup in foil, mounting it, and apllying resin, then removing it.

Posted By: jrdakota25

Date Posted: January 05, 2007 at 9:41 AM

well a buddy of mine talked me into putting to kicker 10 cvx's in instead of the jl w7... but you say make a mold over my transmission hump ... why cant i use mdf for that or is it better to use fiberglass and if i do it with fiberglass how many layers should i use and how do i attach the mdf to the glass

-------------

If at first you dont succeed then sky diving isn't for you.

Posted By: killer sonata

Date Posted: January 05, 2007 at 11:36 AM

ive used a small metal mesh and it worked just fine. no sagging since the holes were too small.

Posted By: bigste925

Date Posted: January 05, 2007 at 8:45 PM

i have done a frame out of speaker grill mesh but grill mesh like he wants to do is gonna be really hard without some fleece spray glued to it. Just mesh and resin is going to be a hard job to do since you need the resin on first then the mesh. for all that he might as well take the chicken wire or whatever it is he is using and spray glue on the mesh. Put resin on the top side of the mesh. after that hardens flip it over and do resin on the bottom so that the resin goes thru the holes and becomes the "new glue" so that it a: keeps the mat from falling off and b: helps it keep it shape. Then he could do subsequent layers of mat for strength on the rear side as well.

Posted By: bigste925

Date Posted: January 05, 2007 at 9:01 PM

As far as speaker selection goes, It looks like you want some pretty heavy duty sound. Why dont you just do one sub like a 12 w7 or a 10 L7 something thats going to be in the middle of your range which seems to be 1000 to 1200 rms. (you upped it when you decided to do 10" comp vx's) and then that way you wont have to have as large a compartment for the sub as you would if you had 2 subs. Both of those I mentioned are about 750 RMS each. You could make the back of the box start behind where your cupholders are going to be. Do a wall thats like .75 inch thick and then the one for the back of the box thats 1 inch so your drinks dont shake. By doing only one sub your box does not have to extend out as far and then could still be narrow and not flare into the rear seat feet area. Plus if you do one sub you can put in like rear cup holders for rear passengers so it will give it a more stock feel appeal to it. Also you have to look at where you are are gonna put amps in your truck. if you do 1200 watts (RMS- I only talk RMS) worth of sub you need to have a 4 channel to put out at least 80 to 100 watts which means it could be pretty bulky in size as well. all these things must be thought of in design of a hot system. Not sure if that crossed your mind but a few more things for you to think about. And finally, the reason he said to glass over the hump is because wood/mdf doesnt naturally bend, so it wouldnt contour to the shape of the car thus it wont appear stock.

|