fg and mdf

Printed From: the12volt.com

Forum Name: Fiberglass, Fabrication, and Interiors

Forum Discription: Fiberglass Kick Panels, Subwoofer Enclosures, Plexiglas, Fabrics, Materials, Finishes, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=93943

Printed Date: February 12, 2026 at 1:48 PM

Topic: fg and mdf

Posted By: ths_system

Subject: fg and mdf

Date Posted: May 15, 2007 at 6:42 PM

when you guys make a box out of fg and mdf how do you guys join them? just wondering i was thinking of makeing a coustom fg bottom for my truck.

Replies:

Posted By: bellsracer

Date Posted: May 16, 2007 at 2:34 AM

Welcome to 12v first off. Now down to business. There are several ways to join them. Here are a few ways that I frequently use... Times where I use them will vary and there is no exact situation, it is a matter of experience mostly. Ok here you go:

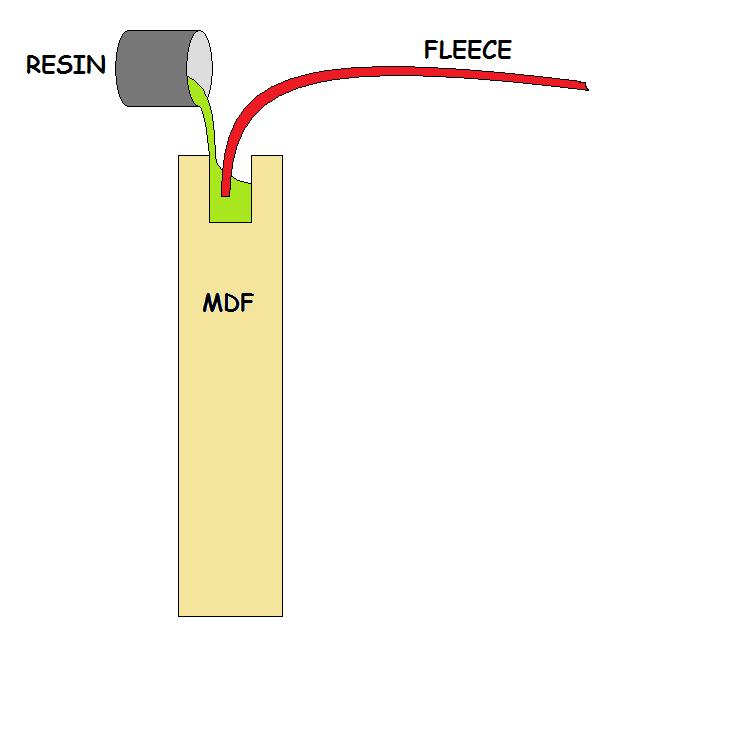

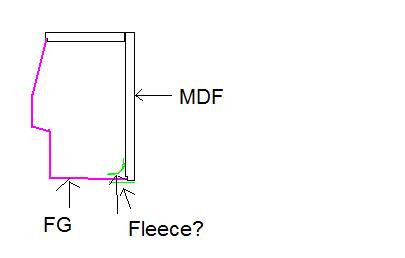

1) Rabbet cut the edge of the wood where it meets the FG 1/8" in and 1/4" high. Staple the fleece to the wood using 5/32" staples (if available). If you are like most people though, 1/4" staples will work too. Add your resin and cure. Next use duraglass to blend the joint area and proceed to bondo and finish.

2) Tape off the non-FG surface of the MDF with 3 layers of masking tape. Let the tape overhang the edge just a little bit. Then hit the edges of the wood with 80 grit sandpaper just to the point where the tape is trimmed off. Try not to sand into the wood. Stretch your fleece all the way around and staple at least 1/2" in on the side with the tape. Trim the fleece an additional inch in from the staples. Apply your resin covering all the fleece including the side where the staples are. Let cure. Using a die grinder with 80 grit sandpaper on it or a 4" grinder with a flapwheel attached, grind down where the edge of the wood is but ONLY to where you hit the tape. Try not to hit the wood (you will have to repair it later if you do). Using a flathead screwdriver, pry off the excess fleece/resin. As the excess is removed, it will pull the staples with it.

There are other ways, of course, but I find these techniques to be the strongest. I hope this helps out though.

Ganbatte ne!

-------------

Never send your ducks to eagle school.

The difference between ordinary and extraordinary is that little extra.

The 3Ls of life: Learn from the Past, Live for the Present, Look to the Future.

Posted By: quadraphonic

Date Posted: May 21, 2007 at 11:45 PM

This was actually a question I was going to ask. I was going to make a trunk enclosure (left side of the trunk in my 2003 Toyota Echo. Based on the design I'm going with right now, I was going to FG the back, sides and bottom of the enclosure. I know that I'm using MDF for the mounting surface, and thought I'd use it for the top of the enclosure as well, since I want it flat, and thought that would be fairly easy to do. A few questions based on your response above.. 1. The rabbet edge seems most appropriate for the front of the enclosure (and maybe even the top). You mentioned stapling fleece to the wood, did you mean FG? If not, can you explain more about the FG, MDF, fleece joint? 2. Should my box top be MDF, or should I use fleece?

Posted By: bellsracer

Date Posted: May 22, 2007 at 11:17 AM

1) Fleece is easy to form for a more form fitting curve, then you would apply FG mat on it for strength. Whether it is on the inside or outside is dependent on the project. There is some debate on this part, but being that it is polyester with a low melting point, fleece will have a chemical bond when you apply your mat to the fleece and resin to it. Now you could use FG for this as well, I never said you couldn't. It is just a lot easier to use the fleece for shape, FG for strength, and MDF for flats & frame.

2) That would be all up to you on what you want your project to be. Either choice is fine really. If you plan on using MDF for your top, consider applying a thin coat of carpenter's glue on the back after you attach it to the FG. It'll fill in the pores and shrink them as it dries giving you a better seal.

I hope this helps. Any other questions? ^-^

Oh yes, I almost forgot, Welcome to the12volt!

Ganbatte ne!

-------------

Never send your ducks to eagle school.

The difference between ordinary and extraordinary is that little extra.

The 3Ls of life: Learn from the Past, Live for the Present, Look to the Future.

Posted By: quadraphonic

Date Posted: May 22, 2007 at 6:12 PM

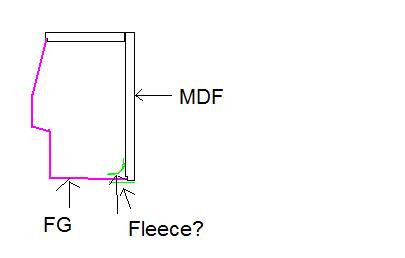

Thanks fo the welcome! I've got what I consider to be enough base knowledge to do a simple enclosure form browsing other forums, but only recently came upon this forum. There's a significant amount of very helpful information. Your explanation helps a bit, though I'm still having trouble visualizing how everything comes together. I made a terrible drawing in Paint, showing how I see it, perhaps we can take it from there Right now I envision the FG fitting in the rabbit edge with fleece being attached to both the FG and MDF to finish the seam. How would you attach the fleece to the FG, just spray adhesive? Here's my artist rendering. Is it close to what you're describing? FYI.. this is a very rough idea of what my enclosure would look like looking through the rear of the car forward. The second image is a photo of the actual location.

Posted By: bellsracer

Date Posted: May 23, 2007 at 12:21 AM

LOL... silly rabbit. First off don't worry about the pain image... those mad art skills are enough for us t ounderstand what you are after.

Now to business:

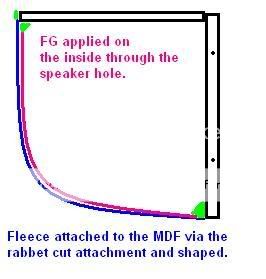

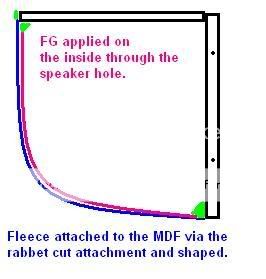

The fleece covers the entire area that you want ot put glass. In other words, where you have just the FG, it's all fleece with resin. after that has cured, you go back ofer the fleece (in your case on the inside of the enclosure and apply FG to it. The fleece is the base, then you apply FG to that to make it strong.

The green spots are where you apply duraglass to reinforce the area that meets the MDF. not 100% needed but really helps out a LOT!

Any other questions?

Ganbatte ne! ------------- Never send your ducks to eagle school.

The difference between ordinary and extraordinary is that little extra.

The 3Ls of life: Learn from the Past, Live for the Present, Look to the Future.

Posted By: quadraphonic

Date Posted: May 23, 2007 at 12:30 AM

I got you.. makes sense. The reason I misunderstood was that I thought it would be easier to simply tape off the area I wanted to glass for the back and sides and go the FG route. I do have another question now, How do I form the fleece to the car? I imagine I still need to tape everything off and keep it protected. Would I use some type of adhesive to hold the fleece in place at that point then? It still seems easier to go pure FG, though I suppose having the fleece base with built up layers of FG on the inside would give me a stronger enclosure.

Posted By: bellsracer

Date Posted: May 23, 2007 at 3:52 PM

You could do that. You'll just have to figure a way to get the FG to attach to the MDF then. FG mat does not tend to hold well when stapling to MDF before resin, so yeah... Instead of fleece you can get a hold of some cheap auto carpet and stretch sections of it to take the shape of the area of the car. I'm sure there are other alternatices I just can't think of them right now (kinda in a rush dear) You could use spray adhesive to hold the fleece temporarily. Ganbatte ne! ------------- Never send your ducks to eagle school.

The difference between ordinary and extraordinary is that little extra.

The 3Ls of life: Learn from the Past, Live for the Present, Look to the Future.

Posted By: e36rok

Date Posted: May 23, 2007 at 10:44 PM

^^^ About the second diagram there, I have a question:

I don't have any fleece on mine, i just have the mold of a corner in my trunk (taped it off and fiberglassed). I want to attatch mdf now for the front, would I still have to stretch fleece OVER that? It fits pretty snug now I don't know about more layers over the outside.

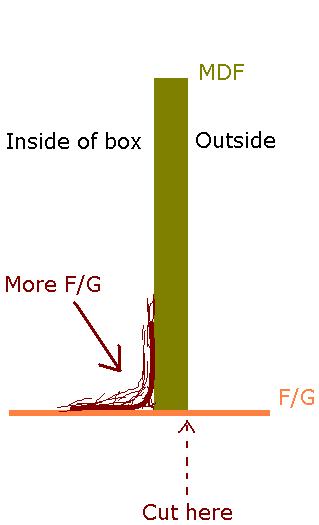

I was thinking attach the mdf with glue or anything temporary (mdf to mdf I'll use screws) and once it's in place fiberglass the inside through my speaker hole where the edges of mdf and fiberglass meet. Around the outside maybe one small strip of fiberglass just so it doesn't look so rough? Then sand the edges down?

Posted By: quadraphonic

Date Posted: May 23, 2007 at 10:48 PM

e36rok wrote:

^^^ About the second diagram there, I have a question:

I don't have any fleece on mine, i just have the mold of a corner in my trunk (taped it off and fiberglassed). I want to attatch mdf now for the front, would I still have to stretch fleece OVER that? It fits pretty snug now I don't know about more layers over the outside.

I was thinking attach the mdf with glue or anything temporary (mdf to mdf I'll use screws) and once it's in place fiberglass the inside through my speaker hole where the edges of mdf and fiberglass meet. Around the outside maybe one small strip of fiberglass just so it doesn't look so rough? Then sand the edges down?

That's what I was thinking too.. or perhaps rough up the mounting edge of the MDF and use resin to mount it, then FG and duraglass the seam. It seems like it would be too hard to start with fleece for the enclosure back.

Posted By: e36rok

Date Posted: May 24, 2007 at 1:33 PM

^^^ Yeah exactly. I think when they say fleece they are talking about somebody who stretched fleece over a frame and then fiberglassed THAT. I have ONLY a fiberglass mold of my corner and want to attach 2 pieces of MDF to finish the front of the box. I am going out to strengthen up my mold with a couple more layers I don't have a camera I will see if I can get my friends tonight to take some pictures so you guys can see what I think quadraphonic and I mean.

Posted By: quadraphonic

Date Posted: May 24, 2007 at 3:03 PM

e36rok wrote:

^^^ Yeah exactly. I think when they say fleece they are talking about somebody who stretched fleece over a frame and then fiberglassed THAT. I have ONLY a fiberglass mold of my corner and want to attach 2 pieces of MDF to finish the front of the box. I am going out to strengthen up my mold with a couple more layers I don't have a camera I will see if I can get my friends tonight to take some pictures so you guys can see what I think quadraphonic and I mean.

Were you thinking MDF for the front (mounting surface) and top? I think you and I are planning identical installs. Looking forward to the photos.

Posted By: e36rok

Date Posted: May 24, 2007 at 3:27 PM

These are some pictures (sorry they are really choppy I took them with a cell phone and had to resize them with PAINT... yeah)

Both the enclosures (still have the tape and foil on one of them)

The right side mold

What I have in mind for the front (not this piece of mdf, just an example)

Could I attach these two by the method I outlined above?

Posted By: icezero

Date Posted: June 27, 2007 at 6:14 PM

suscribed to this thread :D

Posted By: torquehead

Date Posted: June 28, 2007 at 11:40 PM

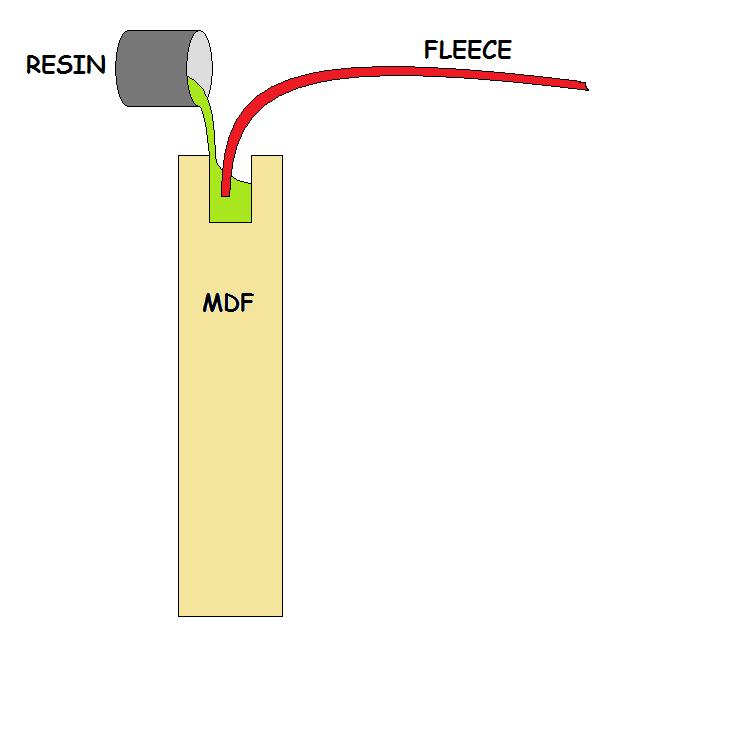

I did a paint of this, because its an alternative of rabbited edges when there is a high demand for strength. I use this method only when well planned and depending on the situations. You can use a circular saw and run it in the edge of the MDF, as you see, you can staple the fleece to the right side to secure it while you fill the channel with resin.

Posted By: e36rok

Date Posted: June 30, 2007 at 3:14 PM

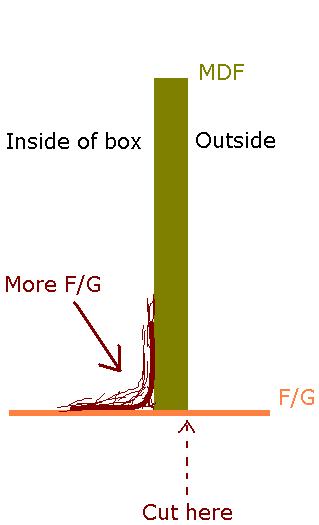

I undertand the rabbet edge concept but what other people are saying is to attach fleece and reinforce and etc. What we have is the fiberglass mold ALREADY MADE, we are NOT stretching fleece over the top but instead making the front and top out of MDF only. Once I have the MDF cut exactly to shape I will attach it with glue for temporary support, and glass all the edges on the INSIDE of the box through the speaker hole for strength, here is my paint of what I mean...

I hope this clears up the confusion and I have one question, how many layers should I do on the inside edges to avoid a break in the sealed box down the road?

Posted By: dstang24

Date Posted: June 30, 2007 at 3:48 PM

The top image would be a trim piece built to fit in the enclosure location. To this piece you could fiberglass the existing shape easily rather than through the subwoofer cutout. From there you build an identical (or slightly larger depending on what nooks and crannies you need to fill) piece as your baffle. Then attatch it MDF to MDF and cut out your speaker hole. The nice thing about doing it this way too: with the single solid baffle you could flush (or what's called recess) mount the woofer(s) by attaching an MDF speaker ring behind it and cutting the main baffle larger. This way the woofer will be flat with the baffle. Hopefully my Paint drawing (obviously on a laptop) is understandable.  ------------- Team Edge Audio

Posted By: e36rok

Date Posted: June 30, 2007 at 8:30 PM

WOW... NO idea what is going on with the post above. Here is my plan

-I have the fiberglass mold made already

-Construct the front and top of my enclosure using MDF and attach these two pieces using woodglue and screws

(before screwing them together I will cut my speaker ring and mount a smaller one behind it to flush mount the sub)

-Attach the MDF "top" to my fiberglass mold using something temporary like glue

-Fiberglass strands on the inside edges everywhere where the fiberglass mold meets MDF

-Once this is dry, add 3-4 layers of matt to the inside edges for support Now the structure of the box will be finished and I can worry about making it "look pretty" later by using a roundover bit on the edges

and filling in gaps on the outside between fiberglass and MDF.

I think the problem people are telling me is the speaker ring will be too small to get a hand in and work? I don't think that will be a problem

I have small hands and that "baffle" idea baffles me (no pun intended :P). - --> Please let me know if my plan should give me any problems if I follow through correctly.

Posted By: quadraphonic

Date Posted: June 30, 2007 at 10:53 PM

The baffle concept is similar to your approach. Whereas you and I were planning on using the mold to trace a cut template on a sheet of MDF to use it as the final surface, he's suggesting to do the same thing, but to then cut of most of the interior of that MDF sheet to allow for easy access into enclosure for FG attachment and reinforcement. Then you would mount your final MDF surface to that baffle (screws/glue). I agree that reaching in shouldn't be tough, but visibility could be compromised a little bit. I'm gearing up to get mine done in the next few weeks here. I'm definitely looking forward to seeing how you progress.

Posted By: e36rok

Date Posted: July 01, 2007 at 12:58 PM

I think I understand now. But how do I go about attaching the middle piece of MDF back to the original piece now part of my enclosure?

I am gaining visibility to strengthen the inside of my enclosure but am screwing myself because it will be hard to reattach this middle piece

back to the original MDF because of the 1-2mm gap from the jigsaw... I'm assuming I have to now fiberglass THIS piece from the inside through

the speaker hole to reattach it?

Posted By: quadraphonic

Date Posted: July 01, 2007 at 5:06 PM

Middle piece is scrap, you would use the FG to draw out TWO sections. One that you would cut the middle out of the make the first baffle piece, and the other that you would cut the speaker opening out of. Then you'd just glue and screw that second board to the baffle piece. It's hard to say if that would be better for what we want to do or not. I almost want to use dowelling with a mounting ring and fleece the sucker, but I think the MDF approach will make for a better blend with the trunk dimensions.

Posted By: e36rok

Date Posted: July 01, 2007 at 7:04 PM

I thought the baffle was for the top side not the side for the speaker ring. It would be pointless to do it with the front side then... all these ideas are confusing me and sound like they are completely pointless and more work. I'm going to do it my way and post pics in a new thread when done in 2-3 weeks.

Peace out.

/thread

Posted By: quadraphonic

Date Posted: July 01, 2007 at 7:17 PM

Still looking forward to it! I should get my butt in gear and make the FG portion. Maybe tomorrow.

|