What is the downfall to using polyester resin versus epoxy resin? I know that polyester resin is heavier and not as strong, but epoxy resin is more expensive and I don't have alot of money to put into this project. Weight isn't a factor for me, but I am planning to do extensive fiberglass work (almost the entire interior). Can someone please give me some help on deciding what to type of resin to use?

Polyester is fine, cheaper and easier to work with. Epoxy is also more hazardous to your health then polyester.

I use marine grade epoxy resin for many projects (not all) for the following reasons.

It is far less hazardous to your health (the type that I use)

It bonds better to all materials that polyester bonds to

It is stronger. Way way stronger

It is more shock resistant (no cracking)

It it’s much more water resistant

It shrinks 1% compared to the 7% that polyester resin shrinks (that means virtually no warping, delaminating, or lines showing up in your paint work)

It wets out fiberglass much better (that means you use less to do the same job)

You can use a fast hardener that works very well at cold temperatures during the winter.

There are no solvents in the epoxy, so you don’t have to worry about it melting what you put it on. For example; you can use Styrofoam to shape your project and then lay the epoxy over that.

Its compatible with carbon fiber

Due to the factors above you can turn out a rock solid product that wont warp, crack, suffer moister damage, or shrink.

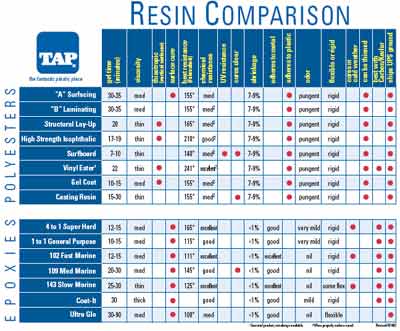

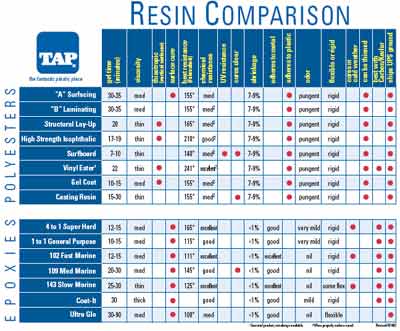

I pay $65 a gallon for this stuff from www.tapplastics.com. I worked them down to this price. This company has various pricing for various customers. All you have to do is ask. I use an expander called “micro spheres” from the same company. With this expander I can make 1 gallon of epoxy into 5 gallons, and that makes this stuff a bargain! ($49 for a 35lb. bag that will last you years). It should be noted that this expander also works with polyester. The point here though is that the price difference is insignificant.

Here are the cons

The way that this stuff is applied when you are doing cosmetic work is totally different than polyester. It requires learning new habits and techniques. Check out www.tapplastics.com for more info. The site is filled with free info and tutorials.

Instead of changing the hardener ratio to change cure time you need to change the type of hardener that you use.

You can not bond polyester products to it (but it bonds extremely well to all polyester products). So using bondo on top of it is out. I make my own bondo substitute using enough expander to make the epoxy as thick as peanut butter and a fast hardener that sets up in about 10 minutes.

If you are looking for simplicity this is not for you. If you are looking for the best product this is the ticket.