first fiberglass project shop display

Printed From: the12volt.com

Forum Name: Fiberglass, Fabrication, and Interiors

Forum Discription: Fiberglass Kick Panels, Subwoofer Enclosures, Plexiglas, Fabrics, Materials, Finishes, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=98648

Printed Date: January 23, 2026 at 6:11 AM

Topic: first fiberglass project shop display

Posted By: offroadzj

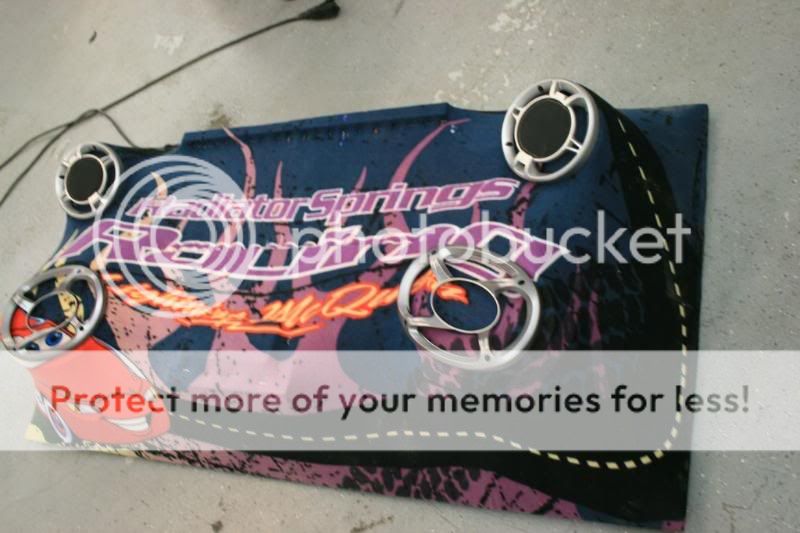

Subject: first fiberglass project shop display

Date Posted: November 05, 2007 at 10:48 AM

Replies:

Posted By: offroadzj

Date Posted: November 05, 2007 at 9:36 PM

ouch.. is it realy that bad that nobody dares to provide feedback??? lol. This is by far a learning experience, so any feedback is greatly appreciated.

Thanks

Kenny

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: mrbubbles00482

Date Posted: November 05, 2007 at 9:57 PM

What did you use to wrap your frame with?

Posted By: jlord16

Date Posted: November 05, 2007 at 10:27 PM

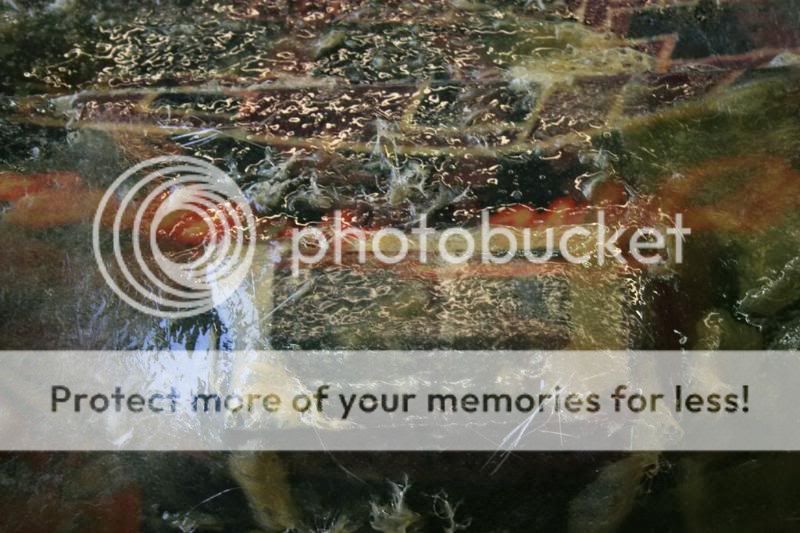

There are afew air bubbles in there that could have been taken out before the resin dries Look at buying either a fibreglass roller or trying to work those air bubbles out with your brush so you dont have to use so much bog Otherwise it looks fine, i like the design as its pictured in MDF ------------- Clarion DB36MP

Infinity Kappa Perfect 10"

Respone 800w Mono

ALPINE MRP-F250

*Custom fabrications*

Posted By: offroadzj

Date Posted: November 05, 2007 at 10:32 PM

the design that is shown in mdf was the original idea. However, as i was stretching the fleece (jsut a fleece blanket from walmart.. lol), one of the supports broke on the 6x9, and instead of undoing all of the fleece, i just simply broke the other one to make it match.. lol. I didnt even realize how many air bubbles there were til it dried, but it really just means more sanding/smoothing, but it should come out pretty good in the end.

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: dbcat111

Date Posted: November 05, 2007 at 10:58 PM

take this as a learning expirience I used to have this problems with the bubbles next time used smller pieces of mat about 3 to 4 inches and cut the brush to about an inch and use a stabbing motion and that will get rit of all the bubbles I know it help me hopefully it can help you

-------------

dbcat

Posted By: offroadzj

Date Posted: November 05, 2007 at 11:40 PM

another method i have heard about from local fiberglassers is to mix resin with the body filler that has the fiber hairs in it witha 50/50 mixture and the correct hardner for the resin. Then using this "milkshake" as a paste to just soak the fleece and it will harden to the same strength as using mat. Any opinions on this? It definately seems to be a much easier approach, but is it really as strong??

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: dbcat111

Date Posted: November 06, 2007 at 9:54 AM

for a project like this it may work but i don't recoment that for a sub box

-------------

dbcat

Posted By: cwwlv

Date Posted: November 06, 2007 at 1:20 PM

is this on the planogram? did u clear this thru DM LOL check out fiberglass forums to get some more ideas

Posted By: offroadzj

Date Posted: November 06, 2007 at 4:43 PM

it is not on the planogram, but it our current display just plain looks like crap. I had it cleared through the store director a couple weeks ago, but now that I have spent the money out of pocket, it doesnt look like Im going to get reimbursed... AWESOME.. lol. But either way, the same products will still be displayed, just in a much cleaner, better looking way.

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: dranged1

Date Posted: November 11, 2007 at 9:28 PM

Man that looks like a hell of alot of work you got your self into. If you need help with future projects let me know and I can give some pointer's. 1st one: next time go to a fabric store like Jo Ann's Fabrics and get some 100% Polyester Fleece, not a blanket from Wal-Mart. And make sure to use 100% Polyester Resin, and a fiberglass roller will help get out the air bubbles. A good tip to have on hand the whole time your fiberglassing is a cup with Acetone in it. It breaks down the resin. Good luck. ------------- Keeping it real day in and day out...be real to yourself and be willing to be a team player!

Posted By: offroadzj

Date Posted: November 14, 2007 at 10:49 PM

i got it carpeted today.... but i gotta get pictures tomorrow. Carpetting is definately not my strong point.. lol. Either way, we didnt have the correct carpet (we only had the thicker style) so it will eventually have to be recarpeted. It definately isnt perfect as we were told to get a display up by black friday, so I had to just throw it together, but the carpet definately hides a lot of the unfinished touches. Overall as a first project, I am definately happy with it. Although it isnt perfect, it looks 1238910340938 times better than our old one. I'll get some pics up asap.

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: offroadzj

Date Posted: November 29, 2007 at 9:57 PM

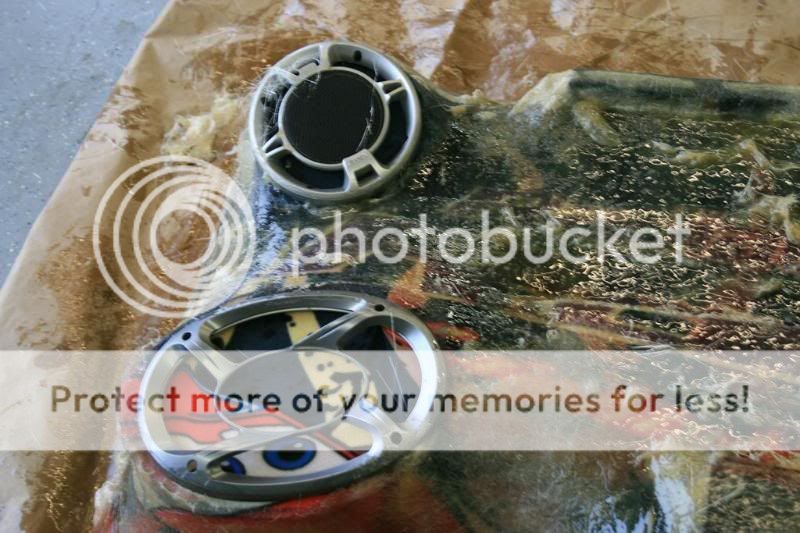

sorry i havent posted updates in a while, but we all know how busy things can get. Here are the temporary finished pics. We only had a really thick, crappy carpet, but we had to get the display finished by black friday, so I threw it together real quick. Once we get some more time I will recarpet it correctly.    I am VERY happy with how it came out.. esspecially for my first time with fiberglass. The only downside is that it is making our sweet jensen's (JS652/powerplus692) sound better than our Polks do on the sales floor :huh:. The acoustics are absolutely amazing. let me know what you think! Kenny The sub was a quick add-on to add some bass to the display. I bolted the box to the wall and flushed a speaker cup into the wall so we can also use it as a test station. And for the record, I know that it is way the hell off center, but I didnt even notice it til after it was on the wall so I will be fixing it when I take it down to recarpet it. ------------- Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: actionjackson

Date Posted: December 01, 2007 at 9:35 AM

if possible can i see pics of the old display

-------------

Jamie Jackson

*CRIMPING AINT EASY*

Posted By: CTOH

Date Posted: December 02, 2007 at 1:09 AM

Has that thing scared any customers off yet? Sorry man,,,but that thing is pretty rough,,,I think you need to go back to the drawing board and start over,,,

Posted By: offroadzj

Date Posted: December 02, 2007 at 6:04 PM

other than the carpetting and the fact that its way off center, what else is rough with it. I dont want to sink anymore money into it because I found out that I am not being reimbursed for it at all. Other than the carpet, and the off-center-ness, I think its pretty good.

Thanks

Kenny

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: CTOH

Date Posted: December 02, 2007 at 9:18 PM

Hopefully you only take this as constructive criticism, if you want to keep doing custom jobs then I think you need a little better direction. If this is all you plan to do and you think its OK then don't read on anymore. When I saw the first picture I could forsee that you were going to have stuff breaking when you were stretching your fleece(or your blanket in this case) because it just didn't look that solid. Your concept and idea did look nice so I commend you for that. Probably the reason part of your skeleton broke was due to the excessively thick blanket you used to do your wrap. Too many people think they need to get all the strength of a structure from their initial fleece. The purpose of this first layer is to give you shape and a base to build on, start with some fleece from a fabric store and take your time to stretch it nice,tight and smooth. Staple it to rabitted edges on your rings and secure it well to the back of your base. When applying your mat, take your time, it is easy to get pretty smooth. You can either roll it or work it flat with your brush, don't try and do too large of an area at a time or your resin will start to thicken and you will be working with paste. Do a couple layers of mat till your desired strength is attained and apply Dynaglass to the enclosure. Work it nice and smooth with a spreader, let it dry and sand it down with 36 or so grit to begin your basic curves and shape. You may want to "spot" dynaglass a few areas you may want to blend a little more. Sand again then get your final shapes and blends with some Rage Gold. Get a carpet that will stretch as much as you need it to and you will have a nice looking project when you are done. If part of your initial structure breaks when wrapping it, don't break the other side to make it even. Start over and restregthen what broke and most of your other supports cause they are probably weak as well. The parts that needed to be blended better are the big hump over the amp and around the head unit it looks like the whole structure is just bulging out of the project, those two things caught my eye right off the bat. It looked like you may have wanted to have the head unit have a flushed look but with the edges of the structure under the surface sticking out like that that took away from any "flushed" look. Yeah its off center but my eye was so distracted by the other stuff that I didn't notice that right off the bat. Take this as constructive criticism and not as a negative,,,

Posted By: offroadzj

Date Posted: December 02, 2007 at 9:41 PM

Thanks for the help. THe bulge above the amp was originally supposed to give the amp a more flushed look, but again it didnt. I know that I should have taken more time on it... but the biggest issue that I had was when I found out 1/2 way through that this was coming out of my own pocket, so it pretty much killed any sort of going an extra mile to have it perfect. I do agree 100% that I should have rebuilt the frame as soon as it broke, but again everything was very rushed because of both funds as well as big brother getting on my back to have it completely finished by black friday, and only being able to work on it for a couple hours a week. When I do my next one, I will definately be taking my time on the entire build. But either way, thanks again for the criticism... that is the only way to learn.

-------------

Kenny

Owner / Technician

KKD Garage LLC

Albany, NY 12205

Posted By: CTOH

Date Posted: December 03, 2007 at 1:43 PM

Sounds to me like "Big Brother" should have paid if they wanna set the deadline!  I know how corporate BS can be though,,,good luck on your next project!

Posted By: ibasspro

Date Posted: December 05, 2007 at 4:46 PM

I wish I could find people with your kind of initiative here. I cannot veiw the pics from my work computer here, but it sounds like a large project. Take this as a learning exp., & continue to play with it......I bet 1st time you had sex, it wasn't porn star quality...things take practice. Not seeing the pics, so I am at a dissadvantage....but here goes. 1. Go to wallmarts fabric section & get some 100% polyester fabric. It is SUPER cheap. Look at it, one side is rougher that the other, put the rough side facing into the box, & the smoothe side facing outward) 2. Make a STRONG skeliton. prefer back & bottom (for a shelf top display). not only glue the MDF together, but either brad nail it, or screw it (depending on what tools ya have). 3. Staple the polyester starting form the center outward (i.e. if you are making a DVD display, staple the inner part of the DVD mount, then proceed to the back & bottom, pulling it as you staple, so all wrinkles come out.....starting at a corner can help, leaving the long straight edges to be pulled so you remove folds & wringles. Not need to pull WAYY tight, but tight enough to bounce a quarter off of, otherwise it will have waves as the resing dries. 4. apply resing to the outside & the inside of the display.....at the same time if possible. For a display, no need to add any actuall mat. (unless it is REALLY BIG) let it dry. 5. Cut off the acess, cut open the DVD hole & carpet. If you didn't have any drips, runs, or cracks, & put the smoothe side out, most carpets will hide any bumpyness that the polyester has. You can pull most carpets like the polyester, to pull wrinkles out, & most the time, keep from having any seems where people can see them. ONLY if you are painting, or vinylin would I sand. keep playing with it, the material are fairly cheap....try making a set of kick panels for a small worth while project. ------------- used to be loud, used to be fast...now I am married LOL

Posted By: karcustom

Date Posted: December 22, 2007 at 7:01 PM

first time is allways the hardest because you feel good about trying to get it finished to show your ideas and talent.keep trying.even small jobs take time. i like the material pattern you used to wrap it with. that would look good on the top of the finished product.remember different and creativety are a must in custom car audio shops.keep up the good work.ps i have over 20plus yrs in the car audio buss.check out some of the work i helped out on. cardomain.com cadillac,escalade( its the blue one).

Posted By: kassdog

Date Posted: December 22, 2007 at 11:25 PM

Just out of curiosity what was wrong with the old one. I work for circuit and actually like it. Its basic and does what it has to do.

|

I know how corporate BS can be though,,,good luck on your next project!

I know how corporate BS can be though,,,good luck on your next project!