Sorry, another question. If I but a length of the lights, say 15 feet, and then cut them into 4 segements...how do I connect wires to them? I assume I have to solder wires to them or something, just wondering if its anything special I need to use. Thanks again.

Cutting is usually done every 3 LEDs and ribbons are marked where that can be done.

Despite my decades of soldering, I recommend the pre-wired joiners for that ribbon type (width). IMO they are more secure and MUCH easier to fit than soldering.

I've bought various ribbons; probably all from eBay. Some were from local suppliers for up to $10 for a 5m roll (Sydney Australia; postage included) and others from China. None were more than AUD$20 per 5m roll for 3528 & 5050 LEDs; 300 & 600 per meter. (Edge lit 335s weren't then available in 5m rolls and were still quite expensive.)

Most have been white but others amber or red (especially the edgelit 335s).

All have been sealed/waterproof types.

Quality-wise I have had no issues but brightness might be the biggest issue. Not that I have compared their specs to actual, but I noted how my (then $12) Jaycar $10

two LED

31mm 12V Festoon Globe is brighter than some cheaper $2 - $3

four LED 31mm festoons that consume twice the current.

Sticky-wise I'm not aware of unsticking in my car lights.

I have a 1m strip of 5050 whites under a melamine kitchen shelf. The plug end has had a bit of assisting tape since day one but recently - after perhaps 6 months of use - the other end has let go, but I'm still merely pushing it back in place. One day I might glue it in place.

But I don't consider the sticky to be poor quality. It may not be "3M quality", but the strip gets quite warm; it is hanging vertically; it's a melamine surface, and sometimes has been lit for well over 24 hours.

My only warning - if it's a 12V strip it means 12V (ie, maybe up to 12.5V) - not automotive 12V.

My prototype license plate

raw 12V strip burnt out relatively quickly. Interestingly is was both LEDs and their resistors that failed (ie, until whichever opened first) which IMO shows how close to max tolerance these ribbons are designed. (Maybe non-waterproof ribbons would have survived.)

Note however that 14.4V versus 12V means 44% more power in a resistor, and at least 20% more power in a LED.

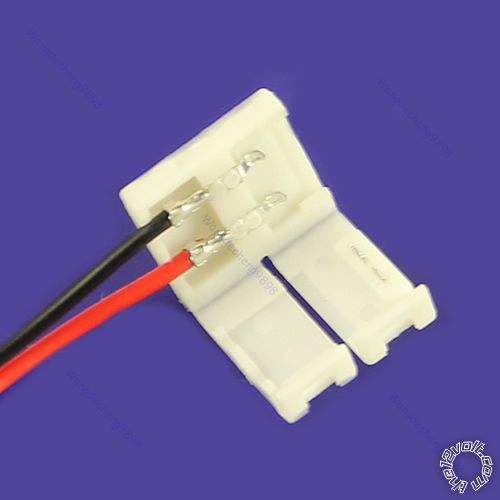

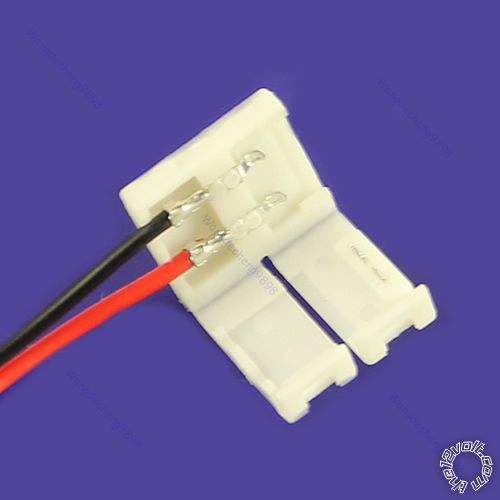

Mine are usually 2 pin as below. Typically 50c each in packs of 10 or more.

As you say, waterproofing is probably irrelevant.

Oldspark, thanks for the response again.

Two more quick questions and then I think I'm good:

1) I found very similar connectors to the ones you pictured on Amazon. They say they are 12V and 10 mm wide. Is this like the lights themselves, do I need to be concerned that an automotive application is higher than 12 volts? Do I need to find connectors that are rated higher?

2) The ribbon I'm looking at says it's 10.15 mm wide; I assume the 0.15 mm extra is okay for these connectors?

Thanks again for the advice.

You MUST get the connector that suits your ribbon - hence width, track spacing, and number of conductors (2 for dumb & single color ribbons).

I think they vary with LED type - eg 3528, 5050, 5050-RGB etc - but I'm not certain.

I suspect the "12V" is merely a description rather than a rating. They probably handle at least 30V.