are my connections good for big 3

Printed From: the12volt.comForum Name: Car Audio

Forum Discription: Car Stereos, Amplifiers, Crossovers, Processors, Speakers, Subwoofers, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=113463

Printed Date: February 07, 2026 at 9:22 PM

Topic: are my connections good for big 3

Posted By: rfhvhtoo

Subject: are my connections good for big 3

Date Posted: April 28, 2009 at 10:09 AM

Hey guys I just want to make sure these connections for the Big 3 are good connects in my ford F150.

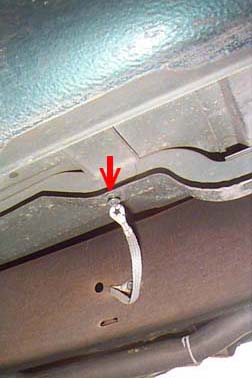

The first connect showing is from my battery (+)

To Altenator (+)

From Engine Block Ground (Between the 2 black tubes)

to Firewall

And from Fire wall to Battery (-) (appx. 9 inches Inches away from the battery (-) terminal as shown below)

My main question is, is the engine block to the Firewall Okay? Im not sure if this is considered a chassy I was never big on maintenence

And is that Engine Block ground Accurate enough (Picture 3)?

Also How do I get that cap off of the Alt (+)? It doesn't seem to budge.

thanks alot

-------------

I can't hear you!

Replies:

Posted By: rfhvhtoo

Date Posted: April 28, 2009 at 10:11 AM

Ford F150

2006

XLT

4.6L

Extended Cab

-------------

I can't hear you!

Posted By: rfhvhtoo

Date Posted: April 28, 2009 at 10:18 AM

rfhvhtoo wrote:

I was never big on maintenence

I meant mechanics. its early

-------------

I can't hear you!

Posted By: aznboi3644

Date Posted: April 28, 2009 at 10:29 AM

-------------

Custom Enclosure Design

Posted By: rfhvhtoo

Date Posted: April 28, 2009 at 1:47 PM

aznboi3644 wrote:

Yeah those connections are PERFECT since we can't even see the battery and alternator connections...check the voltage and resistance of each location...you'll know if its a good connections or not.

Im asking about the LOCATION of the connections not the Specific details in the way Im crimping them.

Should the resistance be consistant throughout the wiring? or is there a approximate number i should be trying to obtain.

-------------

I can't hear you!

Posted By: Velocity Motors

Date Posted: April 28, 2009 at 9:57 PM

-------------

Jeff

Velocity Custom Home Theater

Mobile Audio/Video Specialist

Morden, Manitoba CANADA

Posted By: rfhvhtoo

Date Posted: April 29, 2009 at 4:35 AM

alright then yeah getting as close to absolute zero as possible is the way. But can someone tell me if those locations are good?

I've seen many trucks with the engine block to chassis going under the motor. Thats why im questioning this.

Can I just Ground the engine block to the Firewall (Which is the same place my Batter (-) is grounded to?

-------------

I can't hear you!

Posted By: Velocity Motors

Date Posted: April 29, 2009 at 8:10 AM

"Locations can only be good if metered with a DMM."

Sometimes factory grounds are not that great. That is why we're telling you to use a meter to determine if the locations that you chose are good. We can't tell this from pictures that you posted. Routing the wires under, over or around the engine is irrevelant in this case, just make sure that the resistance is as close to 0 as possible,regardless of location.

-------------

Jeff

Velocity Custom Home Theater

Mobile Audio/Video Specialist

Morden, Manitoba CANADA

Posted By: rfhvhtoo

Date Posted: April 29, 2009 at 1:11 PM

alright I kinda made out my answer from what you guys are saying. I was looking more for the "yes the firewall is also grounded to/with the chassis so it is ok to ground your engine block to to firewall"

because if i was saying i was going to ground my engine block to my tires you would say "no that is not a good location because its not grounded to anything on the vehicle" but you wouldn't tell me to measure it with a DMM.

But since you haven't said Dont ground to the firewall I'll suspect it to be a relevant place

Thanks alot

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 04, 2009 at 9:38 PM

Okay, I'll say it...

Don't ground to the firewall.

Why? Besides a small ground strap from the engine, how many other grounds have you seen on a car's firewill? None? Just what I thought. I've been an auto mechanic for about as long as I've messed with car audio (not full time, but have worked in several shops over the years) and I've never seen anything grounded to the firewall. The engine block is always grounded to the frame. Why? Because the body sits on rubber dampers that you can't see. And so does the engine, in the rubber mounts. The battery is always grounded to the engine, but the engine needs to always be grounded to the frame or you'll just be defeating the point. If you did this, you would actually end up grounding the battery to the firewall too, because if it's not grounded to the engine and the engine is not grounded to the frame, you'll get a lose ground. It IS okay to ground something to the firewall, but I just wouldn't make it the battery OR the engine unless you also have a ground strap/cable going to the frame.

I'm not claiming to be a car audio expert, but I can honestly say I've been involved in auto mechanics since I was a teen. So I'm much more familiar with ground under the hood than many other car audio related questions or topics.

Hope this helps.

Posted By: rfhvhtoo

Date Posted: May 04, 2009 at 10:16 PM

kenwood_nut wrote:

The engine block is always grounded to the frame.

Alright what ive been hearing for my truck is

1/0 ground from battery to firewall

1/0 ground from battery to block

1/0 ground from chassis to block ( how do I go about doing the chassis to block connection? do i need to make my own?)

1/0 + from battery to Alternator

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 05, 2009 at 10:31 AM

Battery to firewall? You still have me baffled there, but it's your ride. You should notice that there is a small braided steel strap attached to the passenger side of your engine on the back of the head that goes to the firewall. This completes the ground to the body. You should also find a ground somewhere going to the frame. If not, it would be easy to make your own with a cable and a couple terminals. It doesn't really need to be a 1 or 0 gauge ground from the engine to the frame. Heck, an 8g is fine. You should already find a hole somewhere to mount it to, but if not, all you really need to do is drill a small enough hole to get a sheetmetal screw into. Some Fords actually used a seperate chassis ground that ran from the underside of the body to the frame rather than directly from the engine. But since the engine gets the biggest ground from the battery, I would run mine directly from my block to frame even if there is one already under the car. Just to make sure. Again, you will most likely find a ground strap going to the firewall from the back of the right (passenger side) cylinder head. You should also find a small ground strap identical to that one that runs from the firewall to the hood IF you don't have the factory Ford little metal flexible ground that contacts the hood when it's closed. So, in my own opinion, although I'm far from being an ASE Certified Tech, is that simple small grounds from firewall to engine and hood are fine, then a 1g from the battery to the block. As far as a ground directly from the battery to the firewall or fenderwell, I suppose a 1g would be okay but on Fords they never had more than a small 8g to the fenderwell from the battery. My present car, a Dodge Stratus, has a 1g ground to the fenderwell only because it branches off to the battery, which is inside the fender. The mount a large post on on the strut tower so you can hook jumper cables or chargers to it. But of all the cars I've owned in the last 35 years, more than 9 out of 10 have been Fords, and all but 2 were pre-emission cars from the 60's to 70's without all the extra crap they shove under the hoods of newer cars. So I'm very familiar with Fords. The good thing here is that a ground from the battery to the firewall certainly won't harm anything, and will only make for more complete system grounds. Most Ford dealers will print you out a page that shows engine electrical connections and grounds for free if they are good dealers. If you ask the parts guys to look up Battery Ground or Ground Strap, their computers should show any and all grounds under the hood. But I have no doubt someone from this forum will have the complete and better answer than mine.

So, yep, you're on the right track! Keep up the good job of grounding stuff. This shows a concern for safety as well as attention to detail.

Oh, the ground straps I'm speaking of on Fords look like these. One is to the back of the right cylinder head, and the other is to the hood. This same type of strap will work for chassis ground. You can snag one at a wrecking yard for under a buck I'm sure.

-------------

Posted By: rfhvhtoo

Date Posted: May 06, 2009 at 12:37 AM

Yes the rope wire i have seen before.

I have added 4 wires already ( All add-ons to OEM).

Battery (-) to firewall

Battery (-) to Starter/Tranny (im gonna guess that is part of the engine block?)

And Battery (+) to Alt

And A wire below the passenger door that is rope like the ones above^^^ in your pictures. they called it Cab to Chassis ground

Now that is 4 upgraded wires so far.

So The Engine Block to Chassis ground should be on the firewall in plain view from under the hood?

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 06, 2009 at 7:21 AM

-------------

Posted By: rfhvhtoo

Date Posted: May 06, 2009 at 8:34 PM

Alright yes I found the ground that goes from the engine to the firewall. It is flat but it has a black (probably electrical) tape wrapped around it so I cant see the design but im sure its the rope.

I also found the ground to the hood that is very small i'd guess 16awg and 6 inches at most. It is in the middle of the hinges so I will probably end up using some 0awg wire and 2 different bolts( but in the same areas as the original OEM bolts) and I will need to get more 0awg for the Engine to firewall as well.

Now will that Engine to Firewall cover the "Engine block to Chassis" ground? Or am i still missing that?

Oh and the ground bolt from my battery (-) to the Tranny/starter is a add on to an OEM connection. So i didnt just randomly put that there just to let you know.

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 06, 2009 at 8:44 PM

Cool. You're finding importand grounds, and that's a good thing!

Everything needs to be grounded, believe it or not, mainly because almost the entire vehicle is sitting or rubber in one way or another. So, you'll want to check to make sure you have...

1. Battery to engine.

2. Engine to firewall.

3. Body to frame/chassis.

4. Hood.

As long as you have all 4 of these, you'll be rockin' out with the bad boys!

The motor mounts are rubber, and there are rubber spacers between the body (where you sit in the cab) and the frame. And there is really nothing to the hood besides hinges, which are not really "secure" because they are loose. So as long as you check and/or ground the above points you'll be good. I hate to suggest it, but I hope you will lay under your ride and look for the ground that goes to the the frame rails from the body. You should find one within a few feet from the engine/firewall area. Once you find it, you're done! If not, you should make your own. It does not need to be much of a thick gauge.

Keep us posted, and good luck man!

-------------

Posted By: rfhvhtoo

Date Posted: May 06, 2009 at 9:13 PM

kenwood_nut wrote:

3. Body to frame/chassis.

Ok I have a ground done that looks the same ground done you have in the picture above with the rope wire done on my truck. Is that the same ground as body to frame/chassis? or should there be another?

The OEM wiring is about 6 inches and goes pretty much from the metal of the truck to the metal of the truck. which i would say has to be frame to chassis.

I should only be missing the hood ground and firewall to engine if that^^^ wire is correct.

-------------

I can't hear you!

Posted By: rfhvhtoo

Date Posted: May 06, 2009 at 9:24 PM

is 3.Body to frame/chassis what you meant when you said frame rails to body ?

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 06, 2009 at 10:28 PM

I'd say you're good now! The body to anywhere under the vehicle is going to be more than likely from the factory, so it's good. And your firewall to engine that you already found sounds good. So, looks like you're off and rolling! Oh, yes, I did mean "Body to frame/chassis". So, yes, you found the right one. You're good now, man!

Oh, the ground to the hood can be as little as 16 gauge! Really, they are never real thick from the factory, and many vehicles just use a thin metal strap. Since nothing is really "hooked up" to your hood, the hood really isn't critical as for the size of the ground. Something simple will work. Heck, even a piece of speaker wire will do. And hey, I'm as baffled as you are about the hood: I never really understood the reason for grounding the hood, but apparently it's important so I never really checked into it much more, and I've seen the hood grounds for many years.

Just wanted to reassure you that at first you may have thought I had experimented a bit too much with a green, leafy vegetable matter as a teen (which I did) and that I may have been trippin. But you quickly found out that what I said you should find, you found. So I wasn't trippin.

Good luck, man, you're pretty much done with any and all grounds. Now it's time to ground your stereo system.

-------------

Posted By: rfhvhtoo

Date Posted: May 07, 2009 at 12:30 AM

And I think I found the perfect Ground last weekend for my amps. You know where the bottom of the backseat is bolted to the frame of the truck (Not where the seatbelt starts but where it ends) well its on the ground and I took that up and scrapped the paint and added a 0gauge wire to a distributer.

Thanks man you;ve been a huge help. Hey I have no problem with the hood ground if the factory has it done then theres some type of theory behind it. So i'll stick with it.

Thanks again. You definately know your stuff and I definately needed to find someone that was deeper into the build of a vehicle then just a general area of where to put the wire. I needed details becuse if i dont understand the reasoning for something then I dont think I know my own stuff... and i like knowing my stuff

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 07, 2009 at 7:13 AM

Glad I could be of assistance. It just so happens that at almost 51 years old, the majority of my automotive experience has been under the hood. Sure, I'd done tranny work, rear ends, brakes, clutches, wiring and lots of underdash stuff. But most of my time my head has been under hoods, and ironically it's been mosty Fords. Like I said earlier, since my first car as a teen, only a few have not been Fords. So I've seen my share of Ford grounds. Now if you had a Dodge truck or something, I'd have to call my best friend and see what he thought. So if you ever have any other questions about your F150, feel free to ask. If I can give you an honest answer, I will. You're doing great. Keep it up. And yes, that seat belt ground should be good. Myself, I would make a new ground hole, but hey, it will work.

What are you mounting your amp to? The sub box? Good. As long as you are not going to just lay it or bolt it to the bare floor. If you're going to mount it on the floor, you MUST put rubber grommets between each screw hole so the body of the amp doesn't touch the metal. Or you can mount it on a piece of wood, then screw the wood down. But if you mount the amp to metal, you'll run the risk of getting a ground loop and you'll hear it in your speakers.

Keep us posted. And good luck with the system!

-------------

Posted By: haemphyst

Date Posted: May 07, 2009 at 8:55 AM

1:

kenwood_nut wrote:

It doesn't really need to be a 1 or 0 gauge ground from the engine to the frame. Heck, an 8g is fine.

WHATEVER SIZE HIS POSITIVE CABLE IS, THE GROUNDS MUST BE THE SAME (or total equivalent) SIZE. That is a current path, and if the alternator demands an output cable that large, where is the return if you suggest an 8 gauge? This is simple electronics, and basic electrical theory. If he is oversizing his alternator cable, (which seems likely, as he never did mention an HO alternator) then he must still have a return (ground) rated for whatever the alternator is rated for.

2:

kenwood_nut wrote:

And yes, that seat belt ground should be good. Myself, I would make a new ground hole, but hey, it will work.

NEVER ground to the seatbolt. It is generally spot-welded to the body (or even the chassis) and is an exceptionally poor choice for a solid return path.

C:

kenwood_nut wrote:

If you're going to mount it on the floor, you MUST put rubber grommets between each screw hole so the body of the amp doesn't touch the metal. {content deleted here} But if you mount the amp to metal, you'll run the risk of getting a ground loop and you'll hear it in your speakers.

This is also not correct. Take your VOM, and test between the chassis and the ground terminal on the amplifier. It will read 0 ohms (or at a minimum, continuity). It is electrically the SAME. Replay all of the times that you thought that screwing the amp to the floor produced noise, and I'll BET you that the amp was grounded to the seatbolt... It's a common occurrence, because that seatbelt- or seat- bolt is CLOSE! It's right there! Why not use it? All screwing to the chassis/frame can do is IMPROVE the return path, by reducing resistance to the return. I have seen instances where removing the isolation from the installation points can REMOVE ground loops, as it adds connections points, therefore reducing total return resistance. Plus, it will oftentimes be a lower resistance than the spot-welded bolt. :)

If he gets a ground loop after all of the good advice that you have given him already, then I would bet dollars to doughnuts that it would be on the head-unit end, and IT'S assocated ground path...

-------------

It all reminds me of something that Molière once said to Guy de Maupassant at a café in Vienna: "That's nice. You should write it down."

Posted By: kenwood_nut

Date Posted: May 07, 2009 at 12:34 PM

haemphyst wrote:

MOSTLY, I agree with everything you have made as suggestions, with these three exceptions:

1:kenwood_nut wrote:

It doesn't really need to be a 1 or 0 gauge ground from the engine to the frame. Heck, an 8g is fine.

WHATEVER SIZE HIS POSITIVE CABLE IS, THE GROUNDS MUST BE THE SAME (or total equivalent) SIZE. That is a current path, and if the alternator demands an output cable that large, where is the return if you suggest an 8 gauge? This is simple electronics, and basic electrical theory. If he is oversizing his alternator cable, (which seems likely, as he never did mention an HO alternator) then he must still have a return (ground) rated for whatever the alternator is rated for.From the engine to the frame doesn't need to be 1 or 0. Engine to battery maybe, but that gives 3 grounds from the engine. I'm thinking you thought I meant the negative from the battery to the block. I've never seen a huge cable from the engine to the frame. But oh well. But no, I did not mean 8 gauge from the battery.

2:kenwood_nut wrote:

And yes, that seat belt ground should be good. Myself, I would make a new ground hole, but hey, it will work.

NEVER ground to the seatbolt. It is generally spot-welded to the body (or even the chassis) and is an exceptionally poor choice for a solid return path.You'll notice I said "should be" and "I would make a new ground hole". But for a beginner with a simple one amp system, it WILL work. Now once he starts adding more to his stereo I would think he should add a new hole. Heck, I've seen a LOT of people use the seat bolts for grounds without any problems. I never do it myself, but it's not like it wouldn't ground.

C:

kenwood_nut wrote:

If you're going to mount it on the floor, you MUST put rubber grommets between each screw hole so the body of the amp doesn't touch the metal. {content deleted here} But if you mount the amp to metal, you'll run the risk of getting a ground loop and you'll hear it in your speakers.

This is also not correct. Take your VOM, and test between the chassis and the ground terminal on the amplifier. It will read 0 ohms (or at a minimum, continuity). It is electrically the SAME. Replay all of the times that you thought that screwing the amp to the floor produced noise, and I'll BET you that the amp was grounded to the seatbolt... It's a common occurrence, because that seatbelt- or seat- bolt is CLOSE! It's right there! Why not use it? All screwing to the chassis/frame can do is IMPROVE the return path, by reducing resistance to the return. I have seen instances where removing the isolation from the installation points can REMOVE ground loops, as it adds connections points, therefore reducing total return resistance. Plus, it will oftentimes be a lower resistance than the spot-welded bolt. :)I guess this is one area where I'll have to continue to disagree. I've forever read in every car audio source I've seen that it is a BAD idea to mount an amp directly to a metal floorboard. Apparently we have different theories on this.

Keep in mind, man, that this guy is doing a very simple install just to have tunes. He has the right ideas on using a large wire gauge and doing the Big 3. That's a start. Now had he said "I plan to enter my car into several IASCA events and install 5 amps and 6 subs along with an assortment of MB Quarts", I would have been a bit more specific as to Do's or Don't's. But we could go on and on about what we agree on or disagree on. This forum wouldn't be needed if everyone in the world all agreed on the exact same thing. But I'm just trying to help a brotha out. Perhaps I should have let someone else answer his questions.

If he gets a ground loop after all of the good advice that you have given him already, then I would bet dollars to doughnuts that it would be on the head-unit end, and IT'S assocated ground path...

When I did my Introduction in this forum, you might notice I didn't say I was an MECP-Certified Installer with 20 years experience. I only mentioned that I've been messing with car audio since the 70's when I was in my late teens. Not once have I ever had a ground loop issue, have never fried a single thing, and only had that famous "alternator whine" a few times with my cheap "toss it under the seat and call it good" systems in the early years. And I'm certainly not going to make any attempts to prove anyone else wrong here in the forum. In fact, after this, maybe it's best if I just leave my advice to myself and let the "experts" solve everyone else's issues. It would save me from having people disagree with things I suggest. You might also notice I've not once posted comments about anyone's systems where the amps are just tossed on the sub box with wires exposed all over the place. I'll admire their brand choices, but would never cut them down or tell them they did something wrong. Which was the case here. I did my best to help someone with an issue I am familiar with: Ford's ground wires.

We still cool?

-------------

Posted By: rfhvhtoo

Date Posted: May 07, 2009 at 3:14 PM

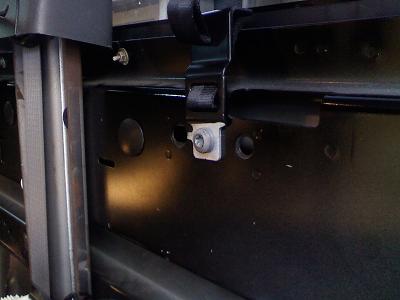

Now this ground is to the frame of my truck on the floor. This isn't good? The terminal is under the flat piece of metal where the the metal is brushed and "Shiny".

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 07, 2009 at 4:37 PM

-------------

Posted By: joch1314

Date Posted: May 07, 2009 at 7:08 PM

I wouldn't ground it there either...if anything remove the pillar and ground your amp under the those panels. It'll look a lot cleaner and should result in a better ground for you once you remove the paint and get to bare metal.

I agree with haemphyst with mounting the amp to bare metal...not only will "electrically be the same" but it can also increase your heatsink so to speak. The heat that is produced from the amp can be transferred to the mounting location, and in climates where your amp is already hot from sitting in a hot car all day, the ability to transfer some of that heat can keep your amp from shutting off or going into protect mode to cool itself off. Yao Ming?!!!

-------------

...half of the truth can be worse than a lie. <----Roger Russell said that..

Posted By: rfhvhtoo

Date Posted: May 07, 2009 at 9:14 PM

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 07, 2009 at 10:18 PM

I realize I might not be taken seriously by some folks, so rather than state my opinion about grounding and mounting, let me go ahead and copy something from the Crutchfield Guidebook Series #000CAR; Advanced Car Stereo Installations and Problem Solving, page 23, Installation Steps to Avoid Noise In Multi-Component Systems. This was sent to me from Crutchfield several years ago, and is only one of the many sources I've gathered valuable information from. Others have included magazines such as Car Audio & Electronics, Car Stereo Review, and many others. I've actually saved technical articles from car audio magazines for many years, and have a notebook full of important and valuable information. I don't just make this stuff up. So anyway, this is what page 23 says in the Crutchfied Guidebook:

1. Mounting: Make sure that none of your components are mounted directly to steel/metal. A lot of components have their internal grounds mounted to the chassis of the component. Mounting a component like this to steel/metal, and then connecting its ground wire, will result in a loop. It is best to mount all of your components on a nonconductive (wood) mounting rack.

2. Distinguish Between Signal Ground and Power Ground: There are two different grounds. The signal path ground is in part a sheild, meant to protect the signals traveling along the inner wire from noise. The power grounds provide the ground paths which allow the various amplifiers within the system to operate. The signal ground can be considered more delicate than the power ground, and it is for this reason that you do not ground the two of them together.

3. The Power Ground: The power ground coming out of the amplifers should be as short as possible. Contrary to popular belief, it is not best to run a return ground lead all the way to the battery. If you are using mulitple amplifiers, it is best to connect all of the grounds to the same area with about 1/2 inch seperating each of them. The metal should be free of paint and grease. The grounds should be secured using bolts/screws with star washers.

4. The Signal Ground: All signal grounds should be connected to the back of the receiver's chassis. The chassis should then be grounded to a ground with either 1/2 inch braided ground strap, or with multi-strand #10 wire. Run this ground to the firewall, or to the heaviest piece of steel/metal you can find. All signal grounds normally are carried through the braided shielding (barrel side) of RCA connector, so running multiple ground wires back to the head unit is not normally necessary. You can test the signal ground with an ohmmeter. Check for continuity between the barrel side of the input RCA jack and the ground lead of the component. If there is continuity, try running that component first with its ground lead disconnected, and check the unit's operation. If the unit does not work, run the ground lead from that component back up to the indash receiver. However, if there is continuity, attach component's ground lead with the amplifier grounds.

So, there you have it, steps on how to avoid noise in mulit-component systems, strait from the mouths of Crutchfield, a leading source in the mail-order electronics industry. If you don't agree with any of it, their phone number is easily found online and I'm sure they would love to hear that they are wrong. But I don't. I don't make stuff up that I post. I get it from many reliable sources, and have collected this information for many years.

Hope this helps. This will be my last addition to this thread. Good luck, dude! You're getting there! I'm anxious to read where you post that it all worked out and your system is noise-free and slammin' hard core!

-------------

Posted By: rfhvhtoo

Date Posted: May 08, 2009 at 5:35 PM

Alright now here are some places for ground that I hahve seen in other forums. But this is actually my Truck.

GROUND #1 (onto one of the 2 Black Bolts on the metal bracket)

GROUND #2 (the gray metal bolt next to the seatbelt Bracket. with the paint scratched away)

GROUND #3 (where the jack bolts to the cab of my the truck) Both pictures same area

And Also I have had problems with amplifiers going into protect mode when mounted onto the bare metal where my ground is. Just though I would throw that out there.

So are these any good areas?

-------------

I can't hear you!

Posted By: aznboi3644

Date Posted: May 08, 2009 at 6:28 PM

-------------

Custom Enclosure Design

Posted By: rfhvhtoo

Date Posted: May 08, 2009 at 7:35 PM

-------------

I can't hear you!

Posted By: kenwood_nut

Date Posted: May 08, 2009 at 9:15 PM

-------------

Posted By: rfhvhtoo

Date Posted: May 10, 2009 at 2:45 AM

Alright guys I think I've got all my questions answered and it seems to be a great thread for people to read. I'm ordering my 0gauge wire(so it all Matches same size color etc) and im finishing up the 2 grounds (Hood) &(Engine to Firewall) before Adding My Hifonics BXI2408D (Approx. 2400wrms) onto the 4 10" pioneer premieres (350wrms each) under my backseat. its a pretty compact box at 3cbft. But its all the room I have. I'm not a "Waller"... Yet. ... Im getting such a big amp because of future upgrades. So it only needs half of its capabilities to push these 4 tens.

... Im getting such a big amp because of future upgrades. So it only needs half of its capabilities to push these 4 tens.

Thanks again!

-------------

I can't hear you!