ok, ok, box designing it is.

Printed From: the12volt.com

Forum Name: Car Audio

Forum Discription: Car Stereos, Amplifiers, Crossovers, Processors, Speakers, Subwoofers, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=115127

Printed Date: February 15, 2026 at 9:50 AM

Topic: ok, ok, box designing it is.

Posted By: methos123

Subject: ok, ok, box designing it is.

Date Posted: July 16, 2009 at 7:09 PM

After everything you all have said about build a box to specs...and on and on. I am going to do it. Even though I had to buy a jigsaw and a couple of saw horses along with the wood, 1 1/4" screws, gorilla wood glue, and a new couple 5/32" drill bits for the pre screw holes. All in all it cost me $112 at Home Depot.

I have used 12volts box volume calculator and slot port length calculator, and have come up with this:

I am tuning the box for 30hz because I want it loud and low.

The outside dimensions are as follows:

18.5 wide, 23 deep, 15 high with 3/4 mdf.

The port will be on the side (slot port) and will be 13.5 high, 2 wide, and 24 long. I will stop 2 inches short of back and go on with the port another 3 inches to the inside of chamber.

With the port volume taken out I will be left with 2.33 cu. ft of inside volume. I will have to brace the inside a little. I haven't decided how yet though. The driver will take up .07 cu. ft. of volume, so I will have 2.26 of inside volume after all is said and done. (Kicker recommends a maximum of 2.25 cu. ft. of inside volume for its ported box.)

What is your opinion on the best bracing with the least affect on inside volume space? Also, I was thinking about using silicone to line the inside of the boxes...what are your opinions and suggestions on that?

I will post pics sometime tomorrow or the next day. I don't know how long this will take. This is my first build, and my brother in law is helping me, (his first build to.) I am on vacation from work, so that is a blessing for this task.

Wish me luck, and please let the suggestions fly, and "do's and don'ts".

thanks.

P.S. I am going to make 2 of these boxes for Kicker CVR 12 2 ohm subs.

Replies:

Posted By: stevdart

Date Posted: July 16, 2009 at 8:39 PM

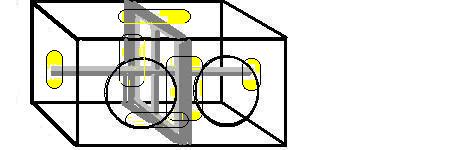

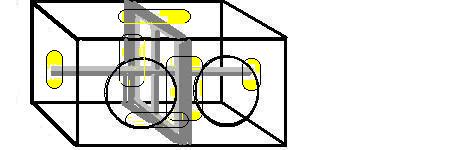

Here are the stress points that braces have to control:

It's sort of self explanatory. The center of any expanse of baffle is the weakest point and so is subject to the most flexing. There have been space-saving braces used and talked about on this forum: metal threaded rods, wooden dowels, pieces of leftover MDF.... Take your time with your first build. It's a lot of fun, so don't hurry it. And make sure you clamp that glue stage securely (bar clamps on hand??) because that Gorilla glue will bust a weak clamp apart in about twenty minutes. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: spmpdr

Date Posted: July 16, 2009 at 11:59 PM

MAKE SURE TO WET DOWN WHATEVER YOU ARE GORILLA GLUING .I MADE THIS MISTAKE!!!It says to to wet everything you glue on the back of the gorilla glue bottle.

-------------

-A vision without a plan is just a hallucination-

Posted By: haemphyst

Date Posted: July 17, 2009 at 12:06 AM

spmpdr wrote:

MAKE SURE TO WET DOWN WHATEVER YOU ARE GORILLA GLUING .I MADE THIS MISTAKE!!!It says to to wet everything you glue on the back of the gorilla glue bottle.

Enh... I've never wet anything except solid wood... MDF has enough pores that it'll hold; and it'll give s FAR longer working time if you DON'T water the surface. ------------- It all reminds me of something that Molière once said to Guy de Maupassant at a café in Vienna: "That's nice. You should write it down."

Posted By: whiterob

Date Posted: July 17, 2009 at 12:48 AM

There is only one thing I have a question for you about. How did you get the port length? I used BassBox to design that enclosure and saw that with that port design you are just under 35Hz tuning with that design, not the 30Hz you said you were planning on tuning to.

Although it is a little bit higher tuning I actually like the way it models up. It will not really take away any deep bass but will give you a little extra output so that port design may be just fine.

For bracing, stevdart was right about where to brace. I always use extra MDF but I think a wooden dowell would work well too. I don't really like the steel rods but bracing is bracing and in the end it is always better to have some rather then none.

The only thing that I suggest is making sure that your braces will not flex. I see too many times where people spend a lot of time on bracing to not have it help a lot. To me, if you add a brace piece that is going to flex badly you are not doing much by adding the brace in the first place. The point of bracing is to prevent a loss of energy from the material flexing. If you fix the wall from flexing but now the brace flexes then you are not any better off IMO. So just make sure any bracing is sturdy and does not flex at all.

I use silicone sealant for all of my enclosures. I know not a lot of people do this but it can't ever hurt. It is cheap and can only help so I say why not do this.

You bought a drill bit which is good. Make sure to ALWAYS predrill before putting a screw in. MDF will split very easily so this is a must.

Everything else looks good and you should be happy with the results.

Posted By: methos123

Date Posted: July 17, 2009 at 7:48 AM

Are the bar clamps necessary if you are gluing and screwing? Won't the screws hold it good enough? My Bro or myself can hold the piece on while the other is drilling. I always thought the clamps were for DIY'ers.

Whiterob, I used the calculator on this website to model the the length of the port. It is right above the calculator for modeling the inside volume of the box. I did it on WinISD a minute ago and it says to go 22" long for a 30hz tuning. What do you all make of this? Which length should I go for here?

thanks

Posted By: methos123

Date Posted: July 17, 2009 at 7:53 AM

Oh, if I really need a bar clamp, how many do I need? Please explain too? (what can I say... I'm a noob at this.):)

thanks

Posted By: methos123

Date Posted: July 17, 2009 at 8:55 AM

If I did cross bracing, how much better would it be to use 3/4 x 2 inch (thickness of wood x height of wood) than 3/4 x 1 inch? thanks

The 2 inch pieces would take up .27 cu ft.

the 1 inch pieces would take up .13 cu ft.

Posted By: DYohn

Date Posted: July 17, 2009 at 9:26 AM

Bar clamps are used by professionals when building speaker enclosures. I like quick-release clamps, especially if screwing and gluing. Here's one I own. You can never over-clamp, more is better: I suggest for gluing the long sides of your enclosure you will want to use at least 6 of these. I am not a fan of Gorilla Glue or any of the other poly glues that expand. It can make carefully measured parts no longer fit together properly. I always use regular yellow wood working glue and have for 35 years withe never a problem. As far as your braces, use whatever you want to use, just be sure to account for the volume it occupies. ------------- Support the12volt.com

Posted By: methos123

Date Posted: July 17, 2009 at 11:50 AM

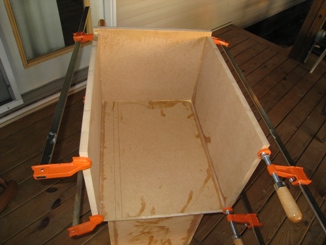

Ok, I went back to Home Depot and got 4 36" clamps. I can't afford any more than that. I see where you need them now though. Thanks.

Posted By: whiterob

Date Posted: July 17, 2009 at 2:34 PM

methos123 wrote:

Whiterob, I used the calculator on this website to model the the length of the port. It is right above the calculator for modeling the inside volume of the box. I did it on WinISD a minute ago and it says to go 22" long for a 30hz tuning. What do you all make of this? Which length should I go for here?

What are you putting in the calculator? I used the calculator on this site and got about 31.5" length to get 30Hz tuning.

What I am using is a port width of 2 inches, a height of 13.5 inches, a volume of 2.26 cubic foot and tuning of 30Hz.

Posted By: methos123

Date Posted: July 17, 2009 at 2:42 PM

I used the volume of 2.85. I am trying to upload a pic of the front piece of my port that cracked ever so slightly when screwing a screw in. It is worrying me for long term. I figured that if I already knew what the volume was going to take up, then I wouldn't even need to use the calculator to find out how long it was supposed to be, so I plugged the 2.85 cu ft. figure in their.

I tried to upload a pic and it said it was 2904 kb too much.

Posted By: methos123

Date Posted: July 17, 2009 at 2:51 PM

Well I won't be upoading any pics because it will only let me upload pics of 60kb! I can't get that low. ):

Posted By: methos123

Date Posted: July 17, 2009 at 2:55 PM

Sorry for the double post, but I didn't silicone the corner of the box that is essentially part of the port now, and I can't silicone that corner of the box on the inside. I put Elmer's wood glue on both surfaces before I clamped and screwed them though. Will silicone on the outside be good for that area?

Thanks

Posted By: stevdart

Date Posted: July 17, 2009 at 3:45 PM

If you've got good straight cuts and a good corner fit, don't worry about not being able to get the caulk into the corner. Things like that are part of life. For pics, I always opened my pic in MS Picture It (or any photo editor) and then did a quick downsize. Picture It has a quick "web quality" downsize button that does the job with one key stroke. The new web-ready pic is saved to your pics folder with the surname "web". Usually the size is under the max limit for this site. A lot of people, though, use a second site that stores pics. Then they link to the pic that way. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: methos123

Date Posted: July 17, 2009 at 5:17 PM

Posted By: methos123

Date Posted: July 17, 2009 at 5:20 PM

Oh yeah, I was wondering if I was supposed to plug in my box volume with the port volume taken out for the port length calculator like whiterob said, or if I was to put in the volume of the whole box with no port volume taken out like I did?

Thanks.

Posted By: i am an idiot

Date Posted: July 17, 2009 at 5:56 PM

methos123 wrote:

I always thought the clamps were for DIY'ers.

I thought you WERE Doing It Yourself. ------------- Let's Go Brandon Brown. Congratulations on your first Xfinity Series Win. LGBFJB

Posted By: stevdart

Date Posted: July 17, 2009 at 6:26 PM

Figure net volume: take out the entire part of the structure that specifically is there for the purpose of porting; the inside air that is dedicated to the driver (but not to the port) is the net air volume. That's why you end up having to figure and refigure a hundred times when you are venting a box. When you get the face baffle glued onto the box, part of the glueing will be to that cracked inside baffle. It won't amount to anything to be concerned about once it's reinforced with the face baffle. ------------- Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: methos123

Date Posted: July 17, 2009 at 7:30 PM

Ok, I made a mistake and the box is going to be 24.5 long, 15 high, 18.5 wide (outside dimensions). Please help me figure out how long my port should be to be tuned to 30hz if it is 2 wide x 13.5 high. Also how much volume will my final box be minus the port. I got a little confused when whiterob corrected me.

thanks

Posted By: methos123

Date Posted: July 17, 2009 at 8:27 PM

Posted By: methos123

Date Posted: July 17, 2009 at 8:34 PM

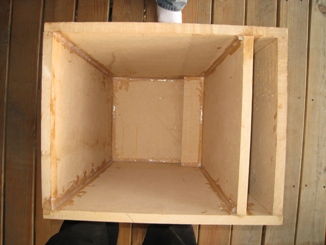

Here is the one with me, it was too large and I didn't realize. The first two above are the second box...I am getting much better with the skill saw. (:

Posted By: haemphyst

Date Posted: July 18, 2009 at 12:25 AM

Your issue? You are not pre-drilling. If you ARE pre-drilling, your drill bit is too small. Also, I find that coarse drywall screws are much better at holding in MDF than are fine thread screws.

MDF MUST be pre-drilled, or you will split as you have seen. Even if you are not so close to the edge that you can't see the de-lamination, it is happening, and your joint is not as strong as it COULD be.

Nice BBQ! :)

-------------

It all reminds me of something that Molière once said to Guy de Maupassant at a café in Vienna: "That's nice. You should write it down."

Posted By: methos123

Date Posted: July 18, 2009 at 7:34 AM

Yes I am pre-drilling. I have a 7"/62 drill bit and 2" deckmate all purpose coarse threaded screws.

I think what happened was that my bro thought if we put small nails on each end of the port, it would be easier to find the middle of the port board with a stud finder when screwing it down. I think that screw got really close to the nail.

At this point I realize that I should have cut the length of the boards to 21.5". We cut them to 23".  So, now I have a box with the port included of 3.05 cu ft.

What I am going to do is put that # in the slot port calculator on this site for the (vb). It gives me a port length of 22" long for 30hz. That displacement is .47 cu ft. Minus .47 cu ft. from 3.05 cu ft. That gives me 2.58 cu ft. of internal volume. I then plug 2.58 cu ft. into the (vb) part in the calculator for the slot port. It now gives me a length of 27" long for 30hz. This length of port takes up .58 cu ft. So, I minus .47 from .58 cu ft to get a difference of .11 cu ft. Minus .11 cu ft. from 2.58 cu ft., and get a final (vb) box volume of 2.47 cu ft. (I will still have to account for bracing and the driver though.)

Is this the correct way to do this?

Please help. My last day of vacation is today, I want to have as much done as possible today.

Posted By: stevdart

Date Posted: July 18, 2009 at 9:20 PM

The figuring never ends. You just have to stop somewhere.

-------------

Build the box so that it performs well in the worst case scenario and, in return, it will reward you at all times.

Posted By: methos123

Date Posted: July 18, 2009 at 10:40 PM

Hey, thanks Stevdart, for replying. I will upload some pics after a bit. I have finally finished and siliconed the boxes and everything. I will hook it up tomorrow. Do I have to wait a whole 24 hrs to let the silicone dry and cure, or can I hook it up tomorrow at noon or so? I finished siliconing at about 9:00pm tonight due to circumstances beyond my control.

Posted By: haemphyst

Date Posted: July 19, 2009 at 12:36 AM

If you screwed it together (and it appears that you have) the silicone is only there to seal the gaps... ou should be fine to hook it up by that time tomorrow. If it's no longer tacky on the outside, and if it feels rubbery, without feeling "structure free" you're all cured up as good as you're gonna get.

-------------

It all reminds me of something that Molière once said to Guy de Maupassant at a café in Vienna: "That's nice. You should write it down."

Posted By: methos123

Date Posted: July 19, 2009 at 6:27 AM

Ok, thanks haemphyst. I have read somewhere that the fumes may be still present, and could eat at your surround and possibly distroy your woofer. That's why I asked.

I put my Kenwood on the baffle of one of them, just to see what it would look like...pretty sweet. I just sold the 2 Kenwoods today btw.

Anyone know of some good carpet that is thin (I have maybe 1/4" on each side of my trunk with these bad boys in there. (:

What do you all think of my bracing? Is it good? It is what Kicker manual suggested.

Sorry so many pics, hope you don't mind. Just want you all to get a good look at these things.

Posted By: haemphyst

Date Posted: July 19, 2009 at 8:15 AM

Silicone, as it cures, creates acetic acid. Also known as common vinegar, I don't think there will be any issues with vinegar fumes "eating" any of your woofer's "soft parts". That cannot be said for ALL adhesives or sealants. Liquid Nails could do some serious damage, but most other water or silicone based products should be fairly safe. If you can breathe the fumes or work around the product without having to use a respirator according to the label, then your woofer'll be safe.

Also, I notice that you have the woofer already installed. If there were to be any damage done, it would not be exacerbated simply by "playing it", and it's already too late... As mentioned, though, you'll be perfectly safe powering it up, once the silicone cures to the point of being solid.

As far as your bracing? That looks pretty decent, but I LOVE overkill... I'd've made a cross brace, and cut a big hole in it rather than just the corner braces... :) And probably two of them. Kicker only recommends what they do to minimize panel flex, where I go all the way to stopping all vibrations to whatever extent I can. I think you'll probably be good to go!

-------------

It all reminds me of something that Molière once said to Guy de Maupassant at a café in Vienna: "That's nice. You should write it down."

Posted By: methos123

Date Posted: July 19, 2009 at 8:33 AM

The woofer is not installed in that picture, it is just sitting there; in the hole. The front baffle is not even installed at that point. Just thought I would let you know that. I just wanted to see what it would look like with a woofer in there. (: I sold that speaker and its twin later in the day. I made these boxes for the 2 Kicker 12" CVR's.

I am going to run the wires through the ports to hook it up. I don't really have very much room to get a terminal anywhere that isn't iffy about where it is located.

Thanks for the reassurance Haemphyst. I appreciate all you guys help.

Posted By: i am an idiot

Date Posted: July 19, 2009 at 9:03 AM

You can still get to the opening of the port to use a router to 1/4 round the sharp edges. The back edge of the port is no longer accessible to do the same there. Sharp edges can introduce non-musical sounds AKA port noise. The surfaces that I would have rounded are colored in the following pictures.

------------- Let's Go Brandon Brown. Congratulations on your first Xfinity Series Win. LGBFJB

Posted By: methos123

Date Posted: July 19, 2009 at 2:01 PM

Posted By: methos123

Date Posted: July 20, 2009 at 5:15 PM

Hey, what do you all think? I will post a youtube video after a while to show how this sh$# slams! (: Let me know what you think so far. By the way, NO PORT NOISE what so ever...even with straight corners on the ports. (:

Posted By: spmpdr

Date Posted: July 20, 2009 at 6:05 PM

Are you planning on cleaning that install up some? like hiding the wires ,mounting the amp etc. I just dont see the point in going to all that trouble of building the boxes and then not finishing them with carpet and doing a clean install.Thats just my preference though.

-------------

-A vision without a plan is just a hallucination-

Posted By: methos123

Date Posted: July 20, 2009 at 6:19 PM

Not right now. It would be nice though. I ran out of recourses and time for now. All this was on a whim. 3 days before I finished, I decided to go get the wood. Man, I am glad I did. I will deal with the details later.

I am trying to find the song Bass I Love you by Basstronics. I can not find the download without some kind of virus attached to it.

Can someone please tell me how to get the song Bass I Love You from BassTronics and the song that is on youtube a lot by Jeezy, (??). Thanks.

|

So, now I have a box with the port included of 3.05 cu ft.

So, now I have a box with the port included of 3.05 cu ft.