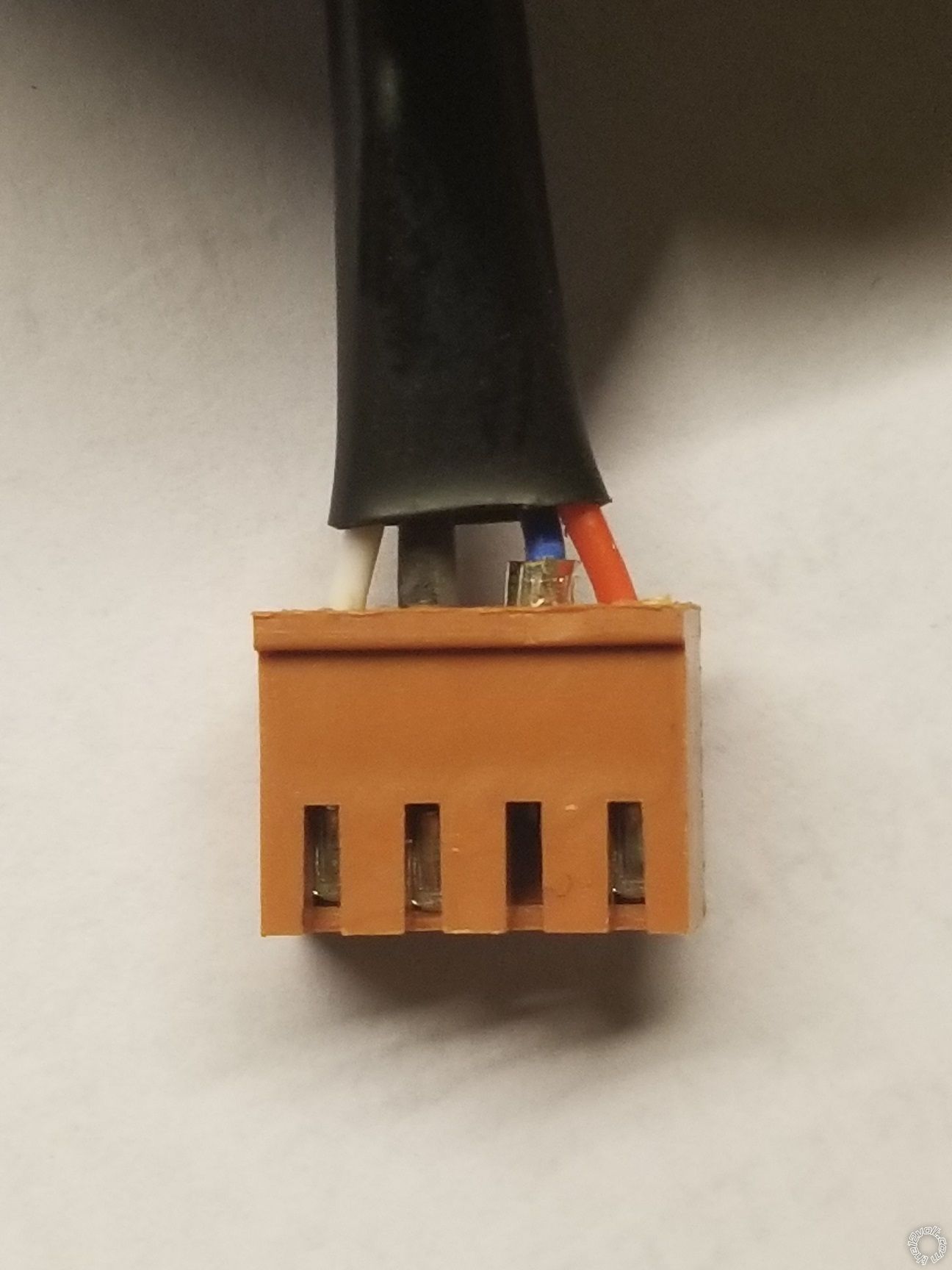

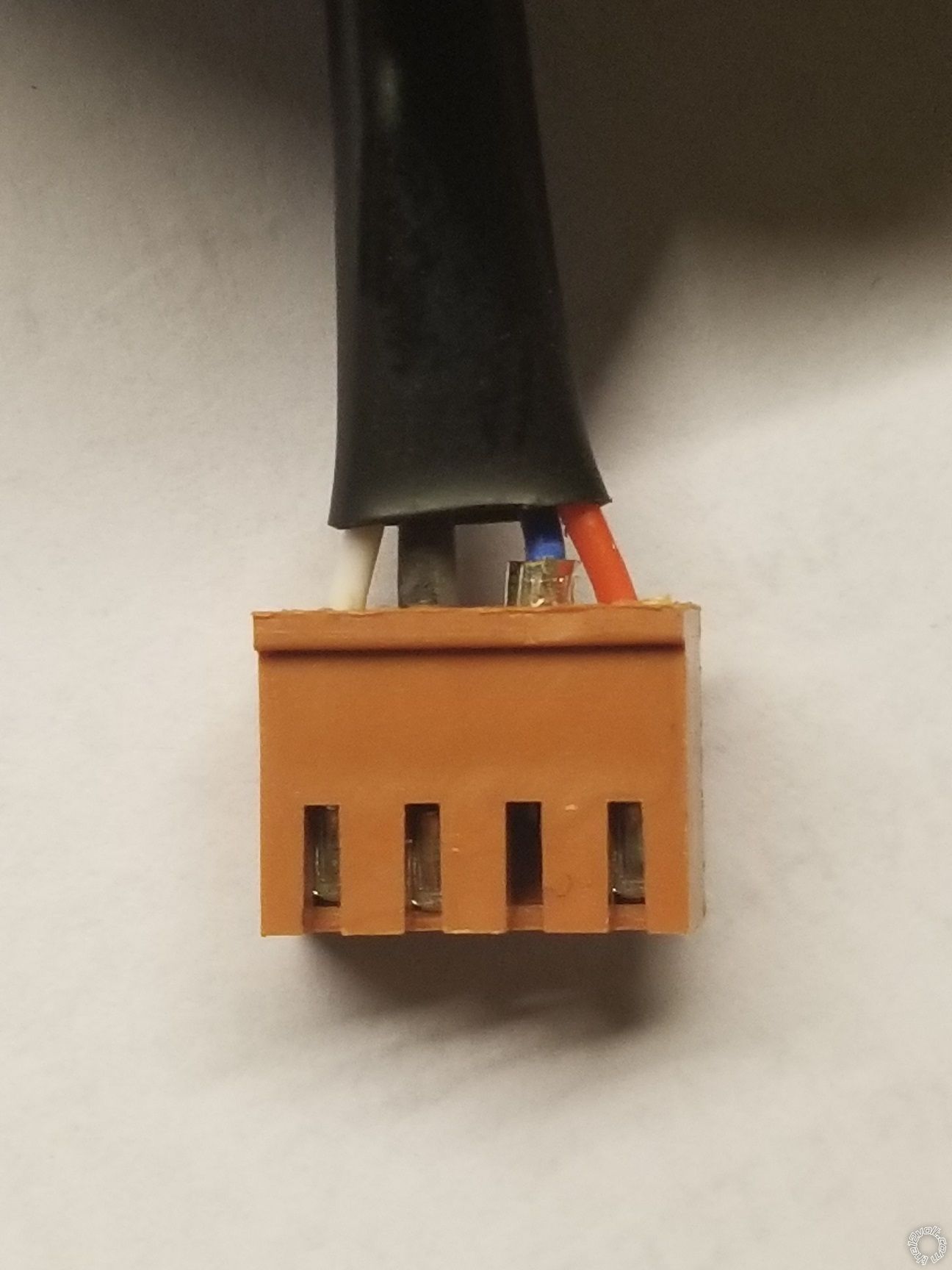

Well yesterday as I was bench prepping another R/S system, as I plugged in the DBI D2D harness it felt a bit "off" but it seemed to be secure so I continued. During final inspection, I gave that connection a good look and was glad I did. Photo below :

One of the data pins was backed out a bit. While it might have programmed OK and passed post install testing because it was making a pressure contact with the R/S's pin, it could fail or worse yet cause intermittent problems down the road. I swapped out that harness and trashed the bad one. Looks like the pin was not oriented correctly to latch in the connector hole.

Bottom line, Bench Prep pays off! I might not have felt or seen this issue if done under the dash.

-------------

Soldering is fun!

Good catch. It sucks trying to troubleshoot issues like that later.

-------------

Steve G

Exactly, Steve! I think we have all seen similar issues. Bad crimps on a relay terminal spade connector, lose in-line fuse holder terminals, etc. You could spend hours re-flashing and re-programming and even swapping the module. The wiring and harness connectors are pretty far down on the suspect list.

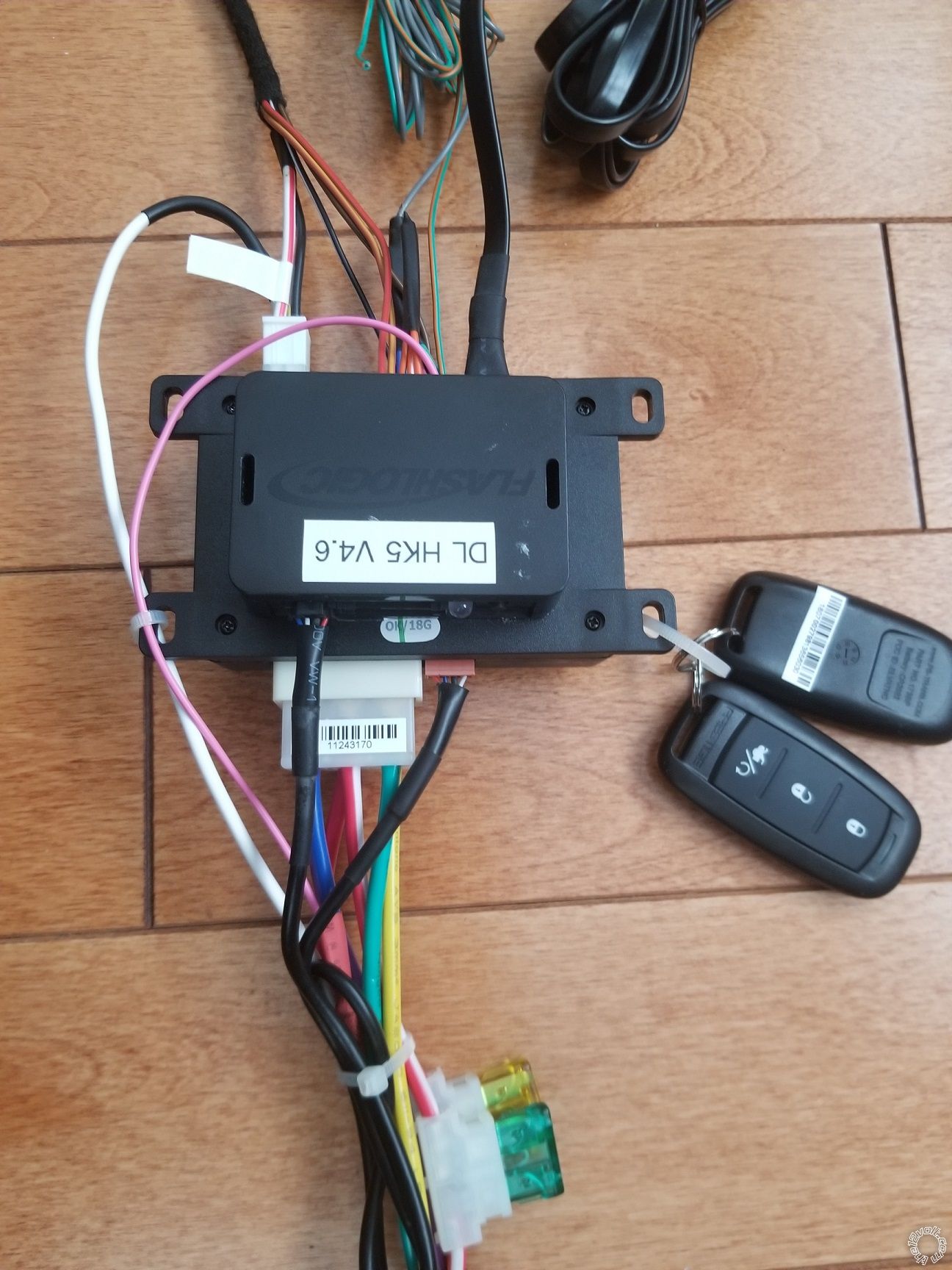

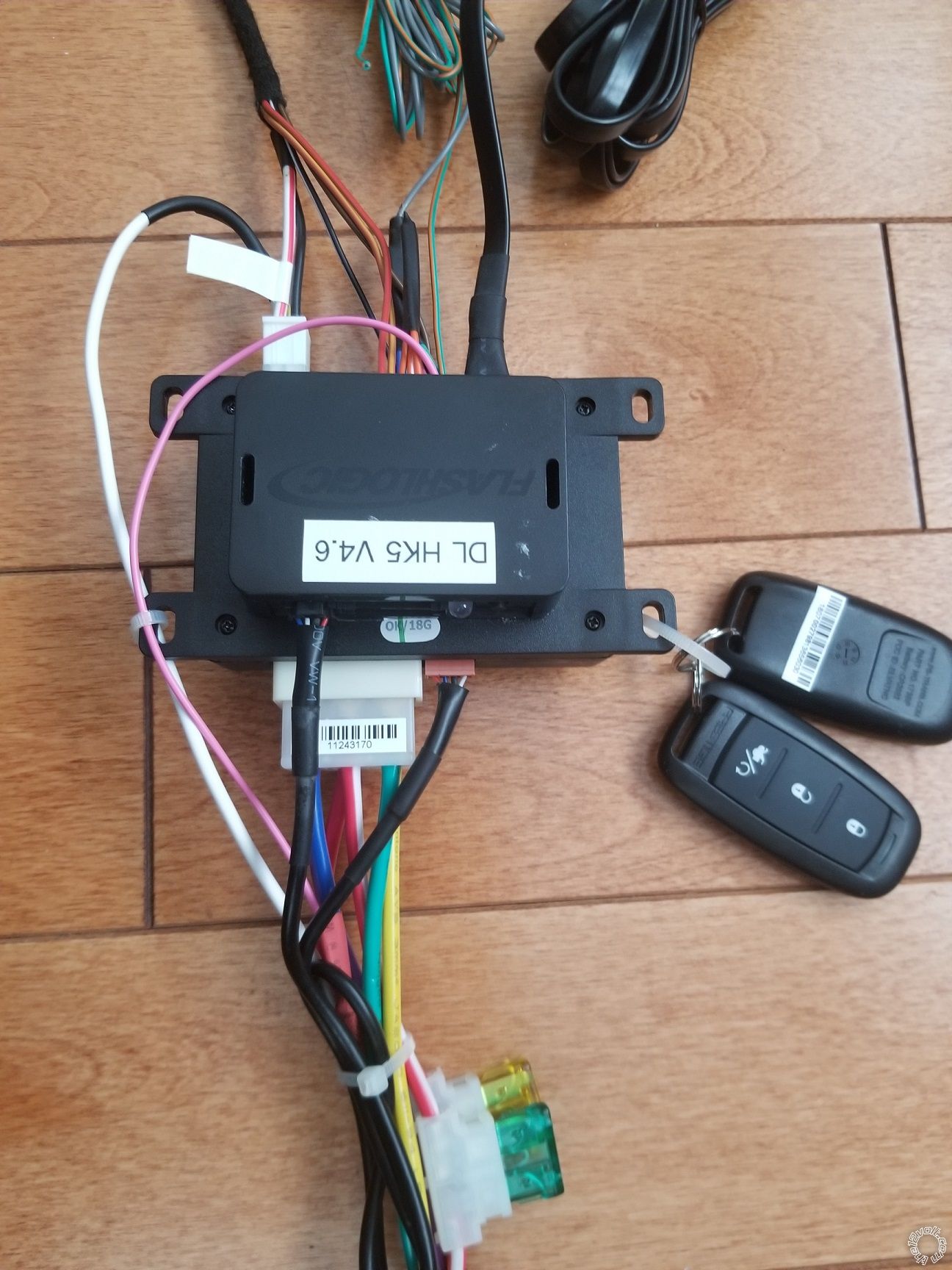

All prepped, programmed, tested and ready to go for Monday...

-------------

Soldering is fun!

Nice bench prep work. I like how you hot glue the bypass to the main unit. I remember having an issue with a brand new remote start install because 2 of the main harness wires were swapped positions in the connector. I was pretty annoyed and only saw it one time but it was enough to make me verify harnesses now for proper wire order each time I start a new install.

-------------

Steve G