Splicing Multiple Wires To one

Printed From: the12volt.com

Forum Name: Car Security and Convenience

Forum Discription: Car Alarms, Keyless Entries, Remote Starters, Immobilizer Bypasses, Sensors, Door Locks, Window Modules, Heated Mirrors, Heated Seats, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=137141

Printed Date: February 19, 2026 at 8:35 PM

Topic: Splicing Multiple Wires To one

Posted By: shafferny

Subject: Splicing Multiple Wires To one

Date Posted: August 22, 2014 at 6:44 PM

Okay, I'm asking this just because I'm curious what you all do and how you handle this. If you have multiple wires, say 3 or 4 12ga wires, you want to solder into one main feed, what is your technique? Do you space out your tie-in points? Do you strip one long section and make all your tie-ins there? Do you wrap them all together around the main feed? What's your preference?

In the past, I've always spaced out my connections, soldering one splice at a time, giving ample time to cool before moving on to the next splice. That way I don't overheat the wire and melt the insulation. I also figure by spacing out my splices, it maintains the flexibility of the wire without creating a point where the conductor might eventually break and fail.

Any pics would be good too. We all love pics!

TIA

Replies:

Posted By: shafferny

Date Posted: August 22, 2014 at 7:12 PM

Posted By: kreg357

Date Posted: August 22, 2014 at 9:13 PM

Nice soldering work.  Your method works well if you have the luxury of access and wire length. In typical practice Your method works well if you have the luxury of access and wire length. In typical practice

installing a vehicle remote starter, it is only two or three +12V power input wires going to one vehicle +12V supply

wire. Usually space is very restricted and only a short distance of supply wire is available. Here is how I do them.

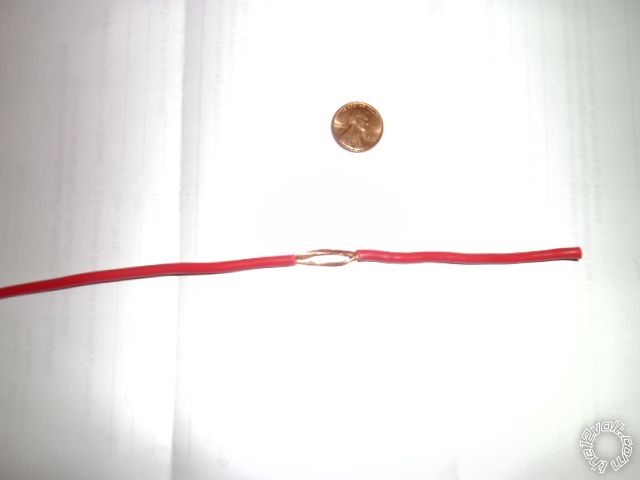

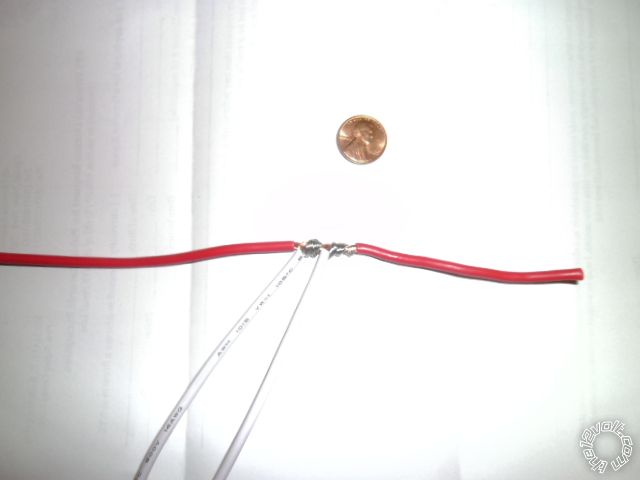

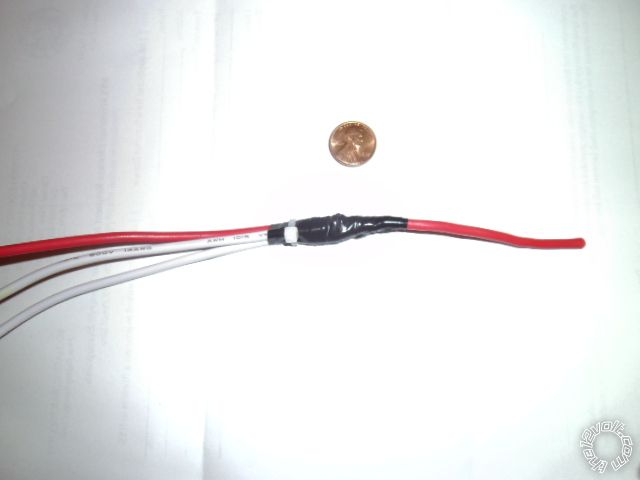

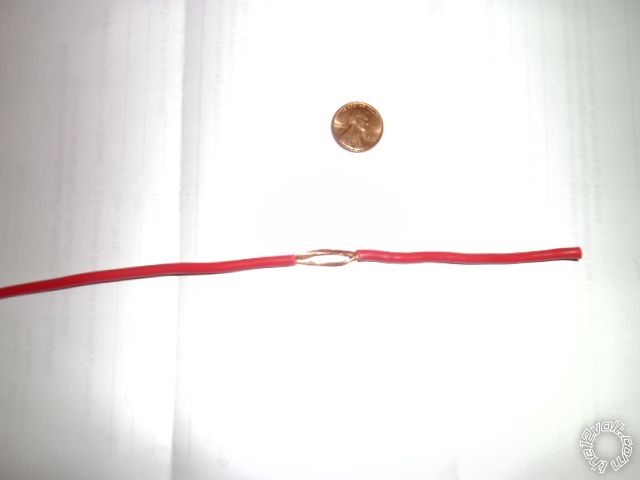

Supply wire.

Supply wire with section of insulation removed.

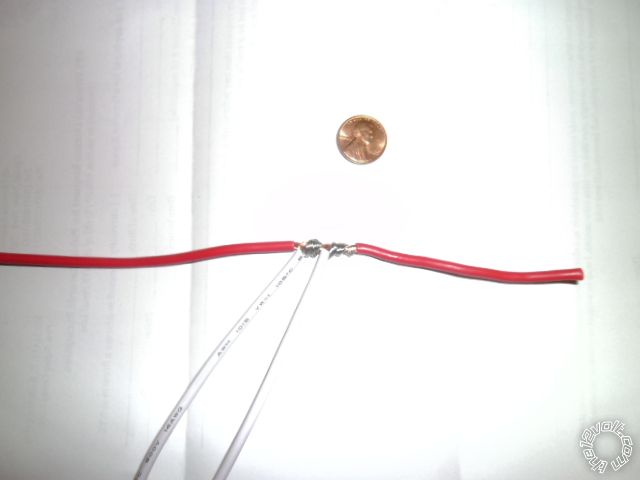

Supply wire with strands split open for "Poke & Twist".

Branch circuit wires stripped.

Poke & twist.

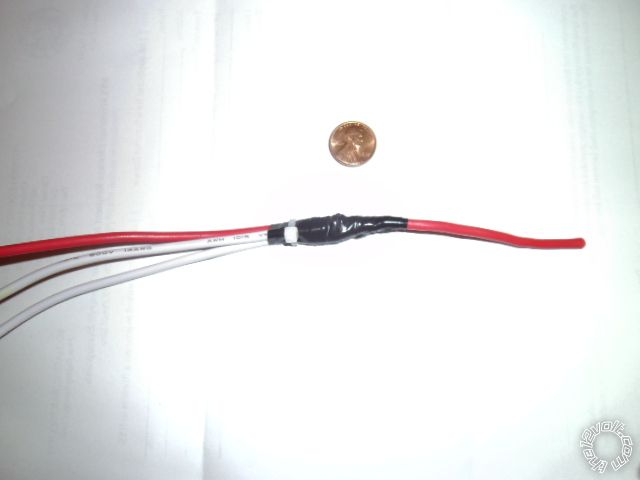

Soldered.

Taped & secured. ( Usually heading down the steering column. )

------------- Soldering is fun!

Posted By: howie ll

Date Posted: August 23, 2014 at 9:35 AM

On a low current ignition switch,e.g. late Fords, Toyotas I bring the three (Viper) leads to one, solder and sleeve them at one inch intervals.

-------------

Amateurs assume, don't test and have problems; pros test first. I am not a free install service.

Read the installation manual, do a search here or online for your vehicle wiring before posting.

Posted By: racerjames76

Date Posted: August 23, 2014 at 10:12 AM

I space them out as well on the DEI stuff RED / black into RED / white, then RED / white into red etc couple inches apart. The one thing I miss about avox is the fuses being further down the wire. I used to put all power sources behind one fuse (smaller fuse for data only vehicles of course) and it made things a lot neater because all those connections ended up being taped again up to the fuse holder. Now most of the splices occur further out past the extra layer of protection. I end up making more DEI wires longer as a result.  ------------- To master and control electricity is perfection. *evil laugh*

Posted By: howie ll

Date Posted: August 23, 2014 at 10:20 AM

I agree with RJ, in fact IMO DEI are making a major mistake with those fuses adjacent to the unit.

Back in the day with Clifford A/Guard and I/Start, you received separate fuses and they were installed adjacent to the source.

In fact for low current I de-pin the heavy duty wires and substitute 10amp cable = 16 gauge US?) I have loads of the right connectors.

The reds get a single 25 amp fuse, I've even gone down to 15 with no problems.

-------------

Amateurs assume, don't test and have problems; pros test first. I am not a free install service.

Read the installation manual, do a search here or online for your vehicle wiring before posting.

Posted By: racerjames76

Date Posted: August 23, 2014 at 10:46 AM

Yeah Having the fuses close to the unit sort of leaves a good bit of wire only protected by the factory fuses, and in some cases only a fusible link. (Wire that melts at a certain temperature). For a while I did solder a new fuse holder at the end but we ran out of avox spare harnesses. When you try to explain that sorta thing to a salesman/parts manager you tend to get just a blank stare. On the low current installs I usually just the 30s in place. I suspect they are just acting as jumpers in most cases anyways. Aside from the old school GM stuff. 50a + on each of 2 10 gauge power wires. You better fuse up and spread that load out lest you have a hot melted mess on your hands. Amazing how much damage a blown 30a fuse can do. When it passes 20 additional amps + than it's rating. You can get a knick in the wire and cause it to pop without much to do other than fix the knick and put a new fuse in, but when them things blow...they BLOW.

-------------

To master and control electricity is perfection. *evil laugh*

Posted By: shafferny

Date Posted: August 23, 2014 at 10:57 AM

howie ll wrote:

On a low current ignition switch,e.g. late Fords, Toyotas I bring the three (Viper) leads to one, solder and sleeve them at one inch intervals.

Makes sense. There's not a huge current draw from the ignition to justify tying all the constant power feeds in to the power source wire separately.

Posted By: shafferny

Date Posted: August 24, 2014 at 8:19 AM

Kreg,

Do you always zip tie over the tape like that? Is there a reason? Possibly to protect the sheathing? I've always placed one a couple inches down form the joint, no tape.

Posted By: howie ll

Date Posted: August 24, 2014 at 8:23 AM

I was taught that way it isn't necessary if you tape over all the wires especially at the ignition.

It's adding mechanical strength to the joint.

My colleague cable (zip) ties ALL the wiring to the alarm brain.

-------------

Amateurs assume, don't test and have problems; pros test first. I am not a free install service.

Read the installation manual, do a search here or online for your vehicle wiring before posting.

Posted By: kreg357

Date Posted: August 24, 2014 at 5:12 PM

For me it's just some added security. While I always use Scotch Super 33+ electrical tape, I have de-installed someone else's work that was a few years old and found the tape unraveling. Not sure what brand they were using. I have does upgrades to my own work that was over 5 years old and the tape still looked good enough that the tie wrap was over-kill. The added tie wrap does both, secure the tape and add mechanical strength by keeping the soldered wire together.

Just as good is Howard's method of applying tape over the entire bundle of ignition wires. Howard even uses tape that is similar to factory tape on this outer layer to conceal the added equipment. Stealth and security...  ------------- Soldering is fun!

Posted By: soundnsecurity

Date Posted: August 25, 2014 at 2:12 PM

zip ties are always a good idea though not always necessary. if i have to use low quality tape i always use a zip tie to keep it from rolling back off from heat or cold. i agree that a zip tie is good to add strength to a connection because the less the wire can vibrate the longer it will last. vibration is the only thing that will break a solder joint so the more support you add the longer your connection will stay good. although you be mad at yourself for using so many zip ties if you ever have to uninstall any of your work lol

Posted By: shafferny

Date Posted: August 25, 2014 at 3:59 PM

soundnsecurity wrote:

zip ties are always a good idea though not always necessary. if i have to use low quality tape i always use a zip tie to keep it from rolling back off from heat or cold. i agree that a zip tie is good to add strength to a connection because the less the wire can vibrate the longer it will last. vibration is the only thing that will break a solder joint so the more support you add the longer your connection will stay good. although you be mad at yourself for using so many zip ties if you ever have to uninstall any of your work lol

I'd rather cut a million ties than deal with the sticky goo left behind from tape! Thank god for Goo Gone!

Posted By: shafferny

Date Posted: August 25, 2014 at 4:02 PM

Speaking of tape though...I usually use Super 33 on all my splices and other area where a quality tape counts. If it's just bundling wires or tidying things up, I'll use the cheap stuff. I can see why you would zip tie over the cheap stuff. Good tip!

Posted By: howie ll

Date Posted: August 25, 2014 at 4:07 PM

Kreg doesn't use cheap tape, he uses 33+ and still cable (zip) ties.

I use Scotch 88 on all of my joints where I've been unable to use shrink sleeving but I think 88 is a bit over the top.

-------------

Amateurs assume, don't test and have problems; pros test first. I am not a free install service.

Read the installation manual, do a search here or online for your vehicle wiring before posting.

Posted By: soundnsecurity

Date Posted: August 25, 2014 at 5:47 PM

shafferny wrote:

soundnsecurity wrote:

zip ties are always a good idea though not always necessary. if i have to use low quality tape i always use a zip tie to keep it from rolling back off from heat or cold. i agree that a zip tie is good to add strength to a connection because the less the wire can vibrate the longer it will last. vibration is the only thing that will break a solder joint so the more support you add the longer your connection will stay good. although you be mad at yourself for using so many zip ties if you ever have to uninstall any of your work lol

I'd rather cut a million ties than deal with the sticky goo left behind from tape! Thank god for Goo Gone!

yea i cant stand when somebody mummifies the wires in tape, usually cheap tape, that makes the wires sticky. id much rather use those tiny 4" zip ties. looks cleaner too IMO

Posted By: kreg357

Date Posted: August 25, 2014 at 6:50 PM

Time 3 on those installers that use a whole roll of cheap tape wrapping up their wire looms!!! What a mess to remove!

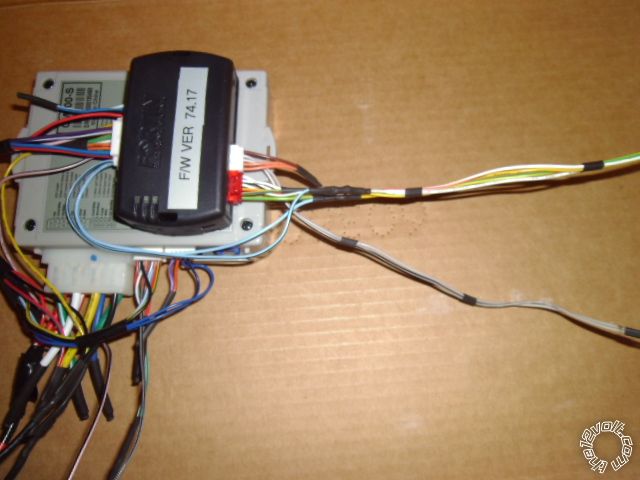

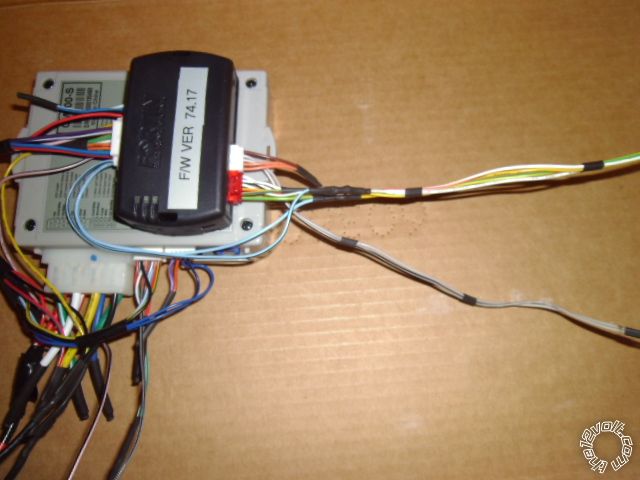

On Chrysler products, where the factory looms are not sheathed, I use 1/4" pieces of heatshrink tube spaced every 3 inches along the loom to "bundle" the wires for the run to their destination. Photo of a CS700-s and EVO-ALL set-up for a Dodge Ram install :

------------- Soldering is fun!

Posted By: soundnsecurity

Date Posted: August 26, 2014 at 6:45 AM

almost exactly what i do except i use tape instead of heat shrink and ill tape most of the wires together when they get within 2 to 3 inches from the alarm brain so that there is nothing hanging loose from the brain. if i have a large wire harness to run and depending on how the factory wiring looks i might run a spiral band of tape along the whole harness but thats as far as it goes for me when wrapping wires in tape.

|

Your method works well if you have the luxury of access and wire length. In typical practice

Your method works well if you have the luxury of access and wire length. In typical practice