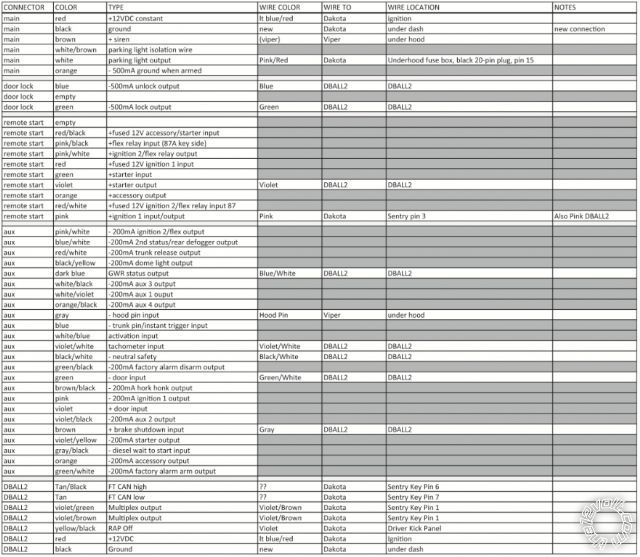

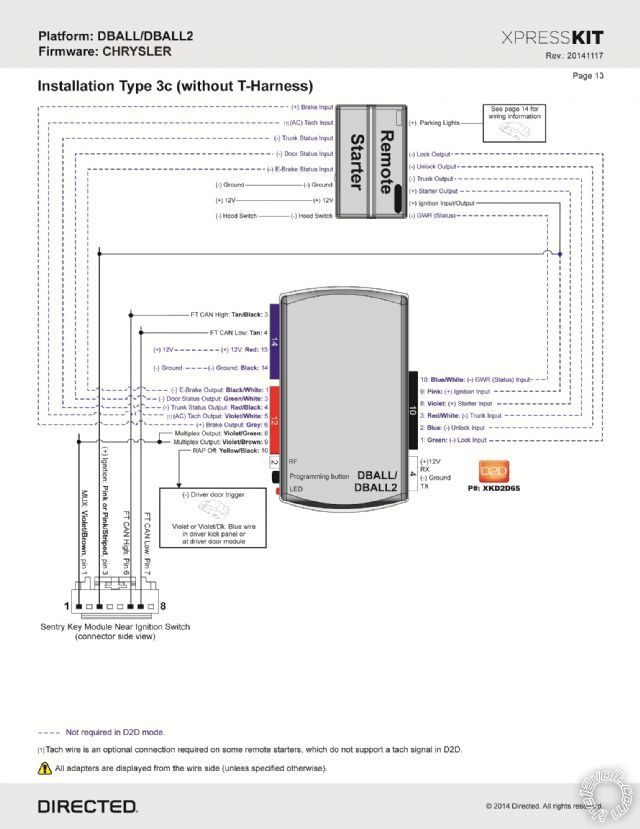

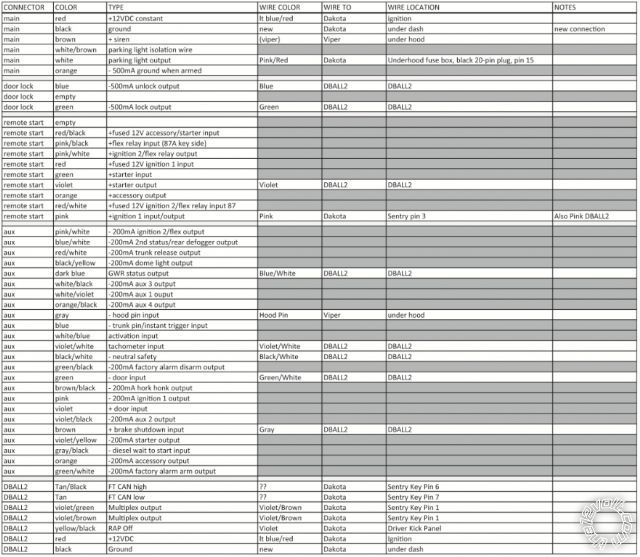

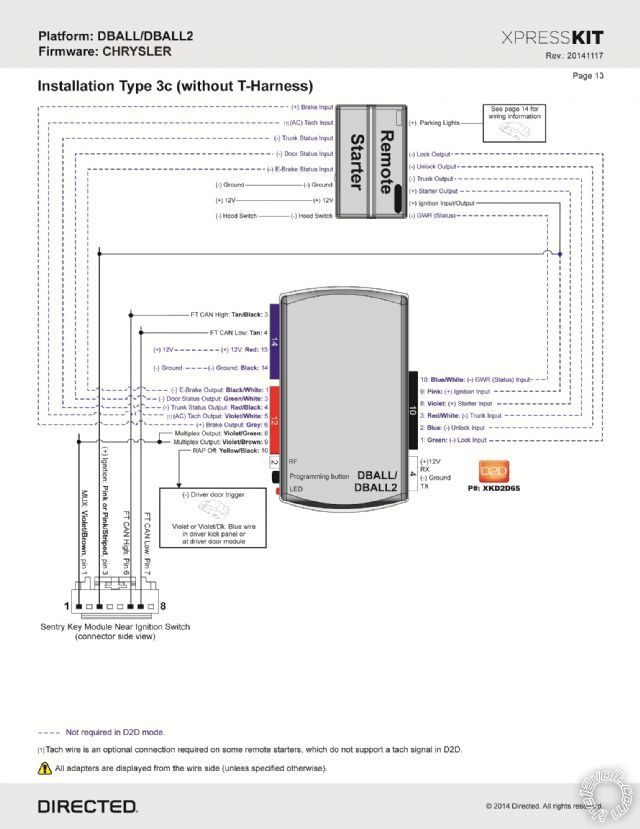

I am attempting to install my first remote start system into my 2008 Dodge Dakota. The remote starter/alarm is the Viper 5706V, and will be connected using the DBALL2. I think that I have all of the connections figured out, but I would like a double check from the local experts

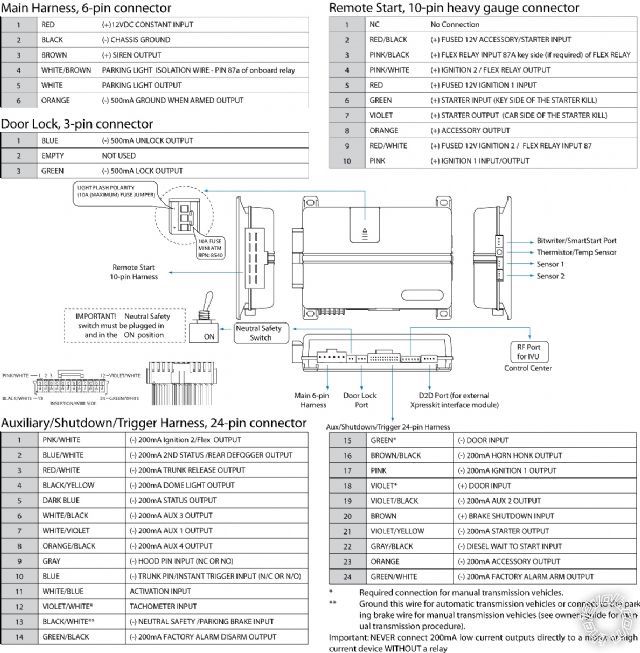

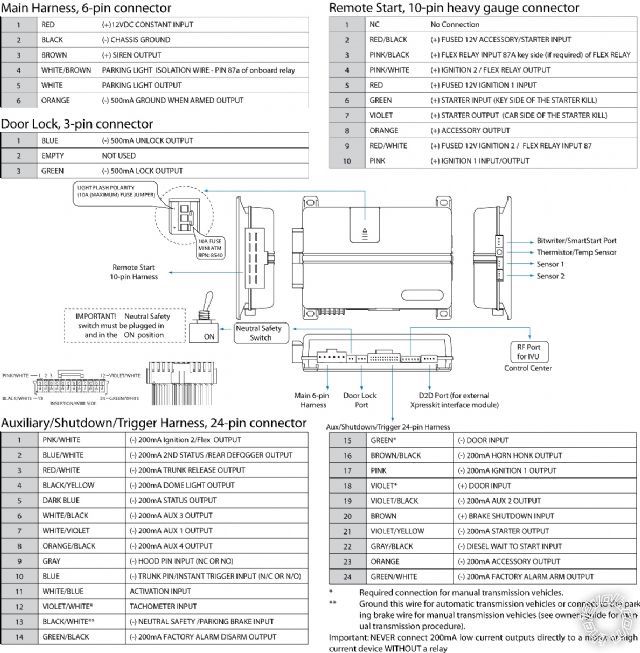

. I have read about issues in using the D2D method and I have decided on using W2W. The wires that I am most confused about are the 10-pin heavy gauge wires on the Viper module.

The dark gray lines are not connected.

Looks good! Only one oversight. You will need to connect the thick Pin 5 Red and Pin 2 RED / Black wire to +12V constant.

I wouldn't use the +12V at the ignition switch harness. It would be better to get all your power from here :

12volts Red (+) battery or IPM **

** The IPM (Integrated Power Module) is in the engine compartment, on the driver fender.

Here are the wire color of the CAN wires at the igntion harness :

CanHigh pin 6 WHITE/ Orange (DATA) @ Ignition switch

CanLow pin 7 White (DATA) @ Ignition switch

-------------

Soldering is fun!

Thank you for the fast reply

. I will make those changes.

Would it make sense to use a pick and remove the unused pins from the connector housing, or should I leave them in for proper connector retention and just tape the ends off?

De-pinning is a pain but makes things look neat. The down side is that if you ever need to make a change, you have nothing to work with. I make a compromise between the two and just cut the unused wires to a bit less than 2 inches, then group them together with heat shrink tubing that covers the ends and, after heating, holds them securely. If I ever need to make a change, I have enough wire to solder on a length of the correct color / gauge wire. Think most installers have a large bag of trimmed ends for adding length to any wire during an install to reach the destination.

-------------

Soldering is fun!

That sounds like a good compromise.

. I have read about issues in using the D2D method and I have decided on using W2W. The wires that I am most confused about are the 10-pin heavy gauge wires on the Viper module.

. I have read about issues in using the D2D method and I have decided on using W2W. The wires that I am most confused about are the 10-pin heavy gauge wires on the Viper module.

. I will make those changes.

. I will make those changes.