RS- proper method for splicing?

Printed From: the12volt.com

Forum Name: Car Security and Convenience

Forum Discription: Car Alarms, Keyless Entries, Remote Starters, Immobilizer Bypasses, Sensors, Door Locks, Window Modules, Heated Mirrors, Heated Seats, etc.

URL: https://www.the12volt.com/installbay/forum_posts.asp?tid=26777

Printed Date: January 28, 2026 at 2:24 PM

Topic: RS- proper method for splicing?

Posted By: webnetxpress

Subject: RS- proper method for splicing?

Date Posted: February 19, 2004 at 7:03 AM

Ok, i've installed a handful of alarms in cars before- mostly using the snap splice blocks. Last night I decided to tackle installing my remote starter. After about 3 hours of working on it (it is working, yippie) i have a new respect for installers. On the alarms most of the splices are minimal gauge and easy to work with. On the RS it seemed like the reverse was true- most are heavy guage and very difficult to splice. So, how do professionals tie into the wires coming off the ignition harness? I'm just curious. I cut mine and resoldered them with the new wire attached. It works, is sturdy, is ugly, and was a royal pain in the ass to do when you have only like an inch of wire to work with. Inquiring minds want to know- how do you guys do it?

Replies:

Posted By: Velocity Motors

Date Posted: February 19, 2004 at 8:39 AM

I always solder and tape the connections and if it's wire end to wire end I always use heat shrink tubing instead of electrical tape. You have the right method, just need to work on your technique. The key to a good solder is a hot soldering iron and good solder.

-------------

Jeff

Velocity Custom Home Theater

Mobile Audio/Video Specialist

Morden, Manitoba CANADA

Posted By: webnetxpress

Date Posted: February 19, 2004 at 8:43 AM

ok. i'm pretty good at soldering- and i was using my trusty butane Ultratorch - that thing really heats up fast. It was more the lack of available wire to work with. I mean those harnesses are pretty much built to the centimeter in wire length, so it was very tight to work under the column like that and add the fact that the wire gauge was so big, it made it somewhat difficult to bend them into position. As I said, all of you installers have earned a new respect from me!

Posted By: jrilla

Date Posted: February 19, 2004 at 9:59 AM

Dont cut the factory wire. Take a razor blade and roll it around in 2 places about an inch apart, then cut the insulation the length between those and peel it off. Then wrap your wire around it enough so it wont fall off while you grab your iron, then solder it.

Some people use their wire stripper to make those first two cuts, but I dont like cutting strands.

-------------

J Rilla

Owner/Installer

Posted By: webnetxpress

Date Posted: February 19, 2004 at 10:12 AM

ahhh, that is a much nicer way to do it, should have tried that. Well, as I said, mine is definetly uglier but still functional.

Posted By: rudbwoy69camaro

Date Posted: February 19, 2004 at 8:07 PM

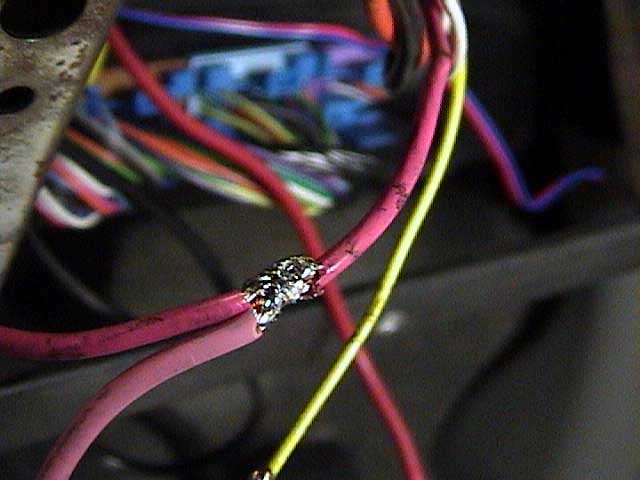

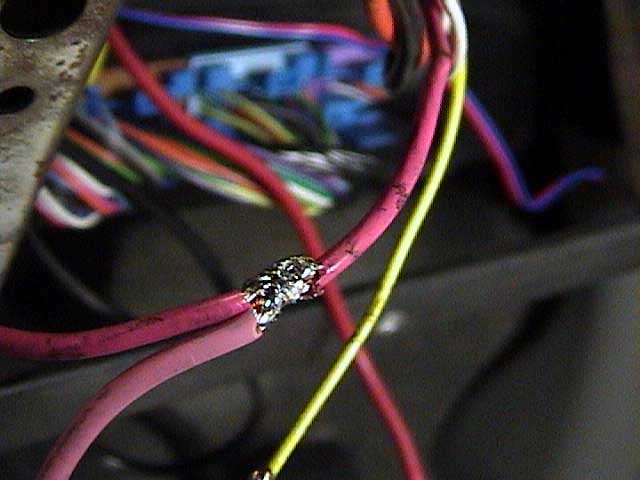

I solder the remote start wires period: I strip back the wire an inch or more, then take an awl, or my probe/test light and make a gap between the strands:

Next, I take the wire that I am soldering to, and insert it and "wrap" it around and flatten it and solder:

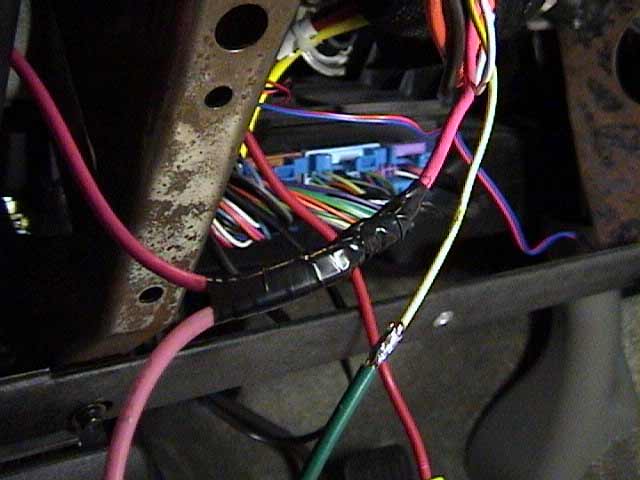

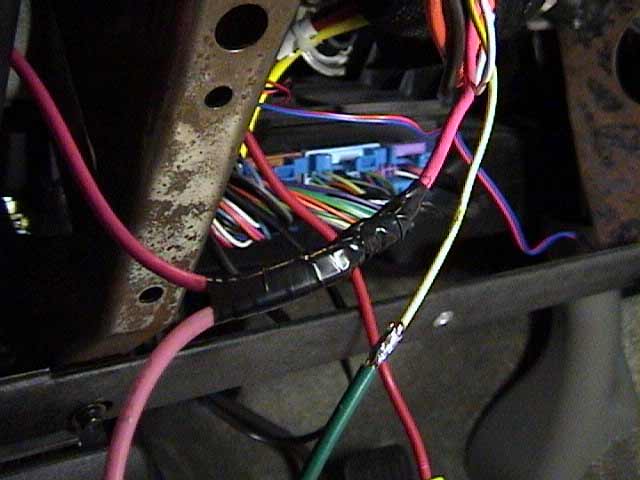

Last step is to tightly wrap it with some 3M super 33 tape:

I've learned that if you're in a tight spot and you have no space to wrap it with the roll, get a butt splice and make your own "mini roll."

Next to the completed one is an "end to end" splice. I "fuse" them together by simply spreading the strands a bit, push them together and solder. And voila ! That's my method. -------------

|