Hey guys,

Been working on a Murphy bed (wall bed) for one of the bedrooms (daughter went off to college, wife wants craft room, but can't give up the bedroom = wall bed).

I had to build this thing extremely heavy-duty due to my brother-in-law's taste in women...anyway, it's one heavy son-of-a-bed!

Toyed with a pulley system; even doubled the amount of pulleys and ropes to the point that it looked like a friggin' Scooner when it was lowered.

So now I'm thinking of going big-time...an ATV winch, with remote control of course.

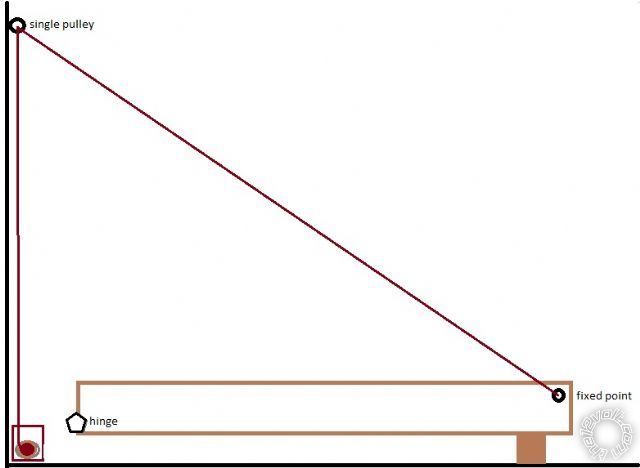

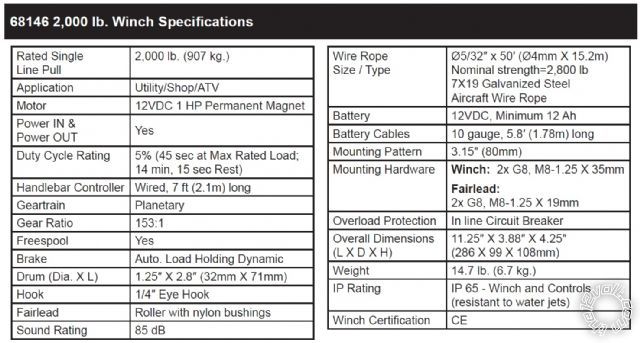

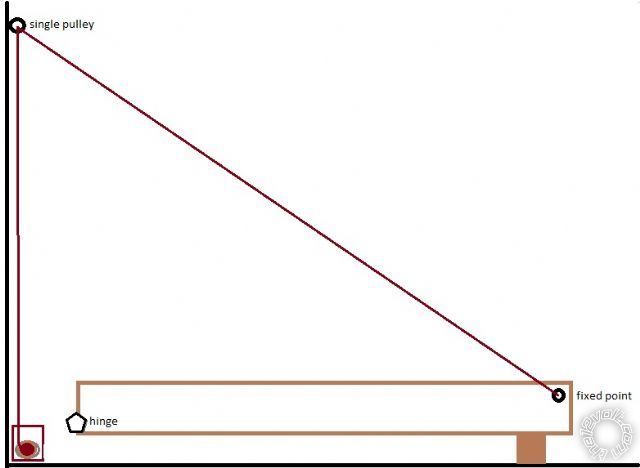

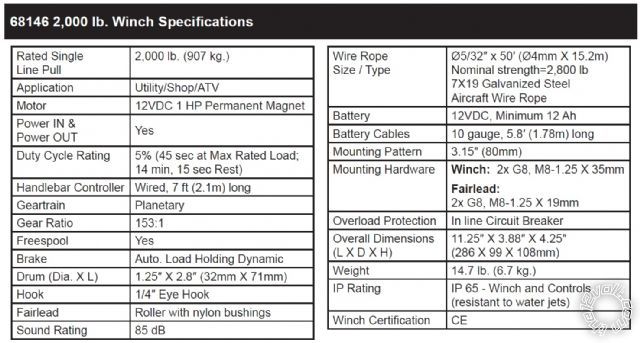

Here's a profile view sketch of the bed mechanics (please don't give me new ideas as it's done already), and farther down, a spec sheet on the winch.

I'm thinking of using the winch off of a ac/dc converter (or visa/versa, inverter, whatever) connected to the wall receptacle versus a car battery/charger setup.

I need to know:

1) what sized converter/inverter do I buy? Will a PC power supply work? If so, what specs? Other, better idea for this part of it is appreciated.

2) Does this winch seem okay? 2000 lb. Electric ATV/UTV Winch with Automatic Load-Holding Brake

I can lift the bed myself and get it verticle, but it's a real bitch, so it's prob 150 pounds straight up, but pulling at a 45-degree angle, I don't know the math formula for that.

p.s.

The "hinge" is a solid bar that runs into a couple side bookshelves. The bed simply pivots around that bar.

.

.

-------------

RadarContact

A PC power supply surely won't be powerful enough to run the winch. You might want to think of a small 12v battery with a maintainer to keep it charged. That way the battery supplies the high current needed for the winch. A power converter with that kind of current capacity would be ungodly expensive. At that point you would be better to buy an AC powered utility winch. They make them in similar size and capacity to an atv winch but they run off regular ac power. They are often used for lifting materials and equipment in a shop. Also what about repurposing a commercial garage door opener to spin the shaft (through some gearing for more torque) and have the shaft fixed to the bed then you wouldn't need an unsightly cable at all. They already run off AC power and have remotes. You could even utilize some of the already existing safety mechanisms that are in place for garage doors.

Hmmm...sounds a little extravagant for something I will use a few times a year. Also sounds a little more expensive than I was looking for.

So, I learned:

Pc power supply won't cut it

Check into electric hoist versus 12v winch

Or use the battery charger idea (which was my first choice but then thought that the release of battery gasses would be bad, so I threw it out as a "less than desirable" idea)

Thank you...more research...

-------------

RadarContact

The motor is 1HP which is about 750W, or ~63A. Assume a 70A draw (inefficiency).

But the amperage may be far less if it does not require 1HP to lift it...

It probably also has an inrush currents.

Battery gases are generally only a problem with flooded batteries which you wouldn't use indoors anyhow. (It may even be illegal as with vehicles/cars.)

Hence the choice would be an AGM battery which have the advantage of usually NOT requiring top-up charges for ~12 months IF FULLY CHARGED. (But hence you recharge it after each use...)

I'd consider a 12V 7AH AGM battery. These are often available for ~$30, though 70A may stress the 7AH a bit. (According to specs, up to ~40A is usually ok and warranted.) Hence 2 in parallel, though I would leave them unparalleled when not in use or when being charged.

The ideal charger would be a smart SMPS charger (C-Tek etc) and these could be left connected all the time to the paralleled batteries (unless one battery fails).

I have a $25 ALDI 4A (3.6A) 6V/12V car/motorcycle(small) battery charger which would be ideal though it has no memory like many C-Teks - eg, power it off and it remembers what mode it was charging in. You'd have to manually choose the "motorcycle" setting to get the ALDI to charge.

I'd assume a bedside switch (with bedside Emergency STOP!) that energises a relay that (energises other relays to) connect the winch and the 2nd battery (unless perhaps they are always always being charged).

have you considered using a tension spring on the pivot bar? you would be able to lift the bed with just 1 finger. If you know how a garage door operates using tension springs then you wont have any problems figuring out how to adapt a tension spring to your murphy's bed. then if you must go electric atleast the force required is reduced to nothing and you can use something more realistic. just my $.02

cahlroach wrote:

have you considered using a tension spring on the pivot bar? you would be able to lift the bed with just 1 finger. If you know how a garage door operates using tension springs then you wont have any problems figuring out how to adapt a tension spring to your murphy's bed. then if you must go electric atleast the force required is reduced to nothing and you can use something more realistic. just my $.02

That's brilliant and I'm embarrassed I didn't think of it! I don't really know how I would engineer it, but it's definitely worth looking into!

Thanks

-------------

RadarContact

I built some custom retractable steps for access into the attic of my garage and I had played around with garage door stretch springs but was always worried about the possibility of them breaking just like the springs used on newer garage doors so I came up with my own counter balance system.

I attached stranded aircraft type cable to some eye hooks on the steps and then ran the cable up into the attic, through some pulleys and then out next to my garage wall to where I then used some all thread and made my own weights out of a bunch of stacked bricks.

Here are some photo's of it:

Attic steps in the down position/brick weights up high:

https://rides.webshots.com/photo/1186968675049730488TJFwyK

Pulley system:

https://rides.webshots.com/photo/1186968735049730488KQUmrk

The bricks are to the right of the NOS painted on the wall.

The steps are not too bad to lift up or drop down and I had played with using a garage door opener mechanism but I thought if it ever fails and the steps are stuck in the upright position, I have no easy was to get at things.

Jim

-------------

1968 Chevy II Nova Garage Find 2012

1973 Nova Custom

1974 Spirit of America Nova

1973 Nova Pro-Street