this is my first post on here , heaps of stuff in these forums but most is beyond me, i've only basic experience with relays and automotive wiring , at first i was looking to just wire my electric fuel pump through the oil pressure switch , so when i hit the starter and oil pressure is over 10psi it will open the switch (normally used for the warning light) switch power to the fuel pump on, when engine shuts off fuel pump is off, or major crash happens etc. then i thought about wiring in the coil to as i've always been paranoid about oil pressure and most the time it's hard to keep an eye on it , so if the oil pump failed or major oil loss , ignition would be cut and save the engine

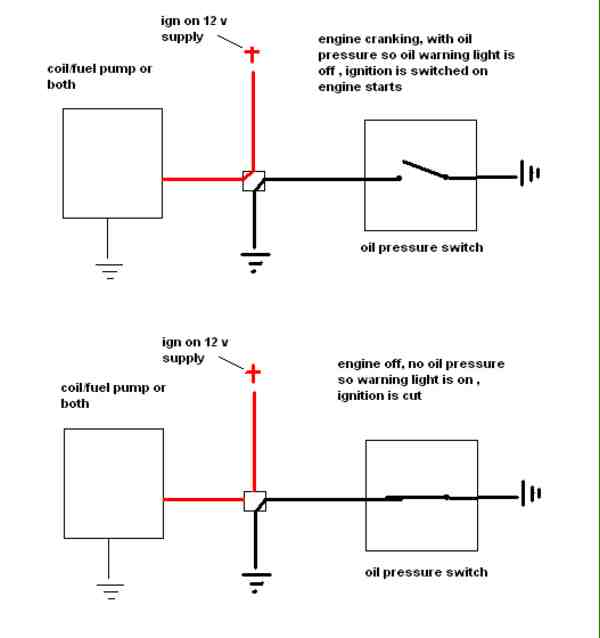

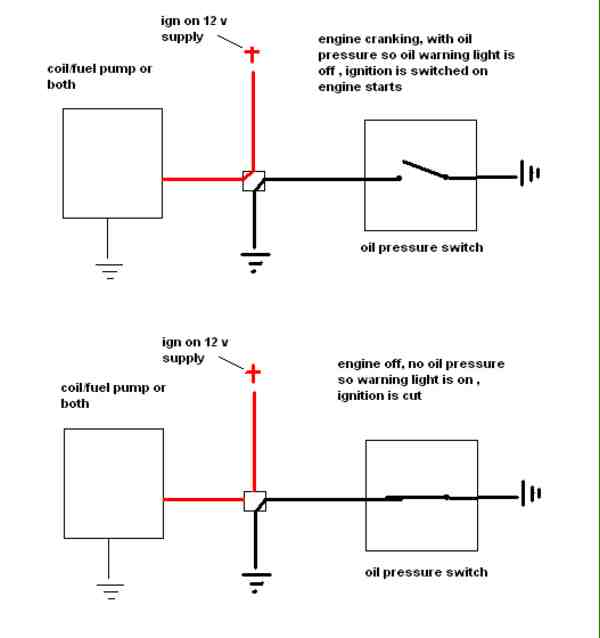

i'll include a pic as it's the best way i can show whats happening

forgot to add any help with what type of relays and how to wire them up would be apprec'd thanks in advance

Before you try this, you need to disable the ignition system to make sure the starter motor will turn the engine over fast enough to turn the oil pressure light off. If it does not turn the light off, your car will never start.

it does get sufficient oil pressure up during cranking, but i'll be using an adjustable hobbs oil pressure switch if i go down this road so it can be adjusted to the sweet spot, other wise i could have it disabled while the starters on ? but i want to try keep it simple and building up oil pressure before it fires it always a good thing

the main bit i'm stuck on is how to make the relay switch power to the ignition/fuel pump on, when the oil pressure switch is circuit is broken

A standard Bosch/Now Tyco automotive relay works is as follows. There are 5 terminals on the relay. Terminals 85 and 86 are the coil of the relay, when 12 volts and ground are applied to these connections, the relay will energize. Terminal 30 is the common connection. Terminal 87A is the normally closed connection. Terminal 87 is the normally open connection. This means that when 85 and 86 do not have 12 volts across them, 30 is connected to 87A. When voltage is applied to 85 and 86 30 now becomes connected to terminal 87.

With power applied to 86 and 30, and 85 connected to the pressure switch, Your fuel pump or Ignition needs to connect to 87A.

Sorry for being late, but you may find the following to be a superior fuel-pump control circuit.

The "Reg" connection is to the Charge Lamp circuit (ie, D+ or L on many alternator/regulators).

The Ig could be any fused Ignition power, or via a fuse direct to the battery.

"Start" is to the starter (cranking) circuit (eg, ignition switch or from the startermotor solenoid etc).

(With thanks to "Tezza".)

If you want the cranking prime function (during starting), you may have to connect a diode in series with 87 to prevent any feedback to the starter solenoid.

Otherwise a plain SPST relay will suffice. For priming (aka bypass), you can then diode-OR the Charge-Lamp & starter circuit or a separate momentary push button.)

If the alternator/regulator fails, by disconnecting the alternator's regulator, the dash lamps (ie, the charge lamp and any diode-interconnected lamps) are usually sufficient to power the relay. (IE - being disconnected, the regulator's earthed "charge lamp" terminal will not hold the relay #86 low.)

This circuit assumes that the fuel pump is NOT used as an engine protection device or "kill switch" (that's what the oil pressure to ignition circuit is for) but is merely required to turn off should the engine stall or ignition be turned off.

It also overcomes the oil-pressure reliability issues (eg - stuck pressure switch; open contacts/wires).

Many cars use this approach for fuel pump control. It is simple and reliable and merely adds a relay to existing circuitry. Newer cars may use air-flow switches if fitted, but these are usually on EFI vehicles whose EMS control the fuel pump anyhow.

(With thanks to "Tezza".)

(With thanks to "Tezza".)