Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Sunday, February 1, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Sunday, February 1, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

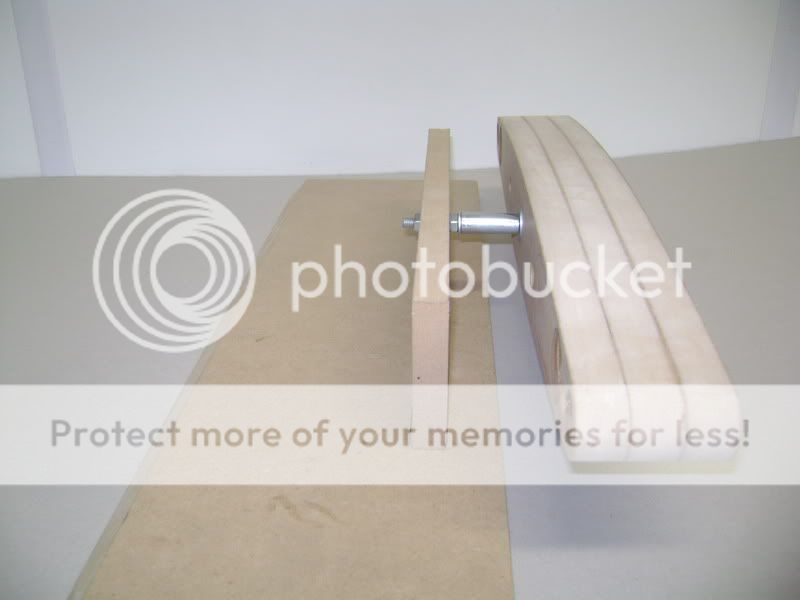

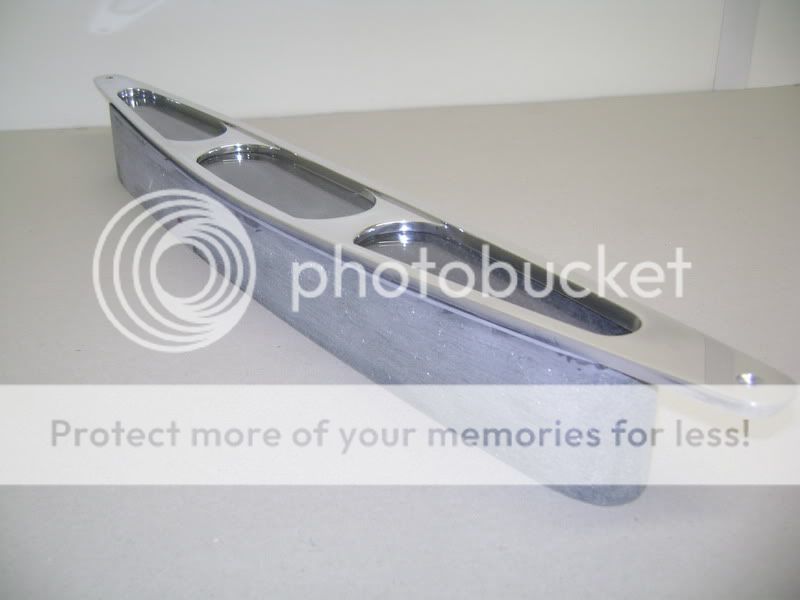

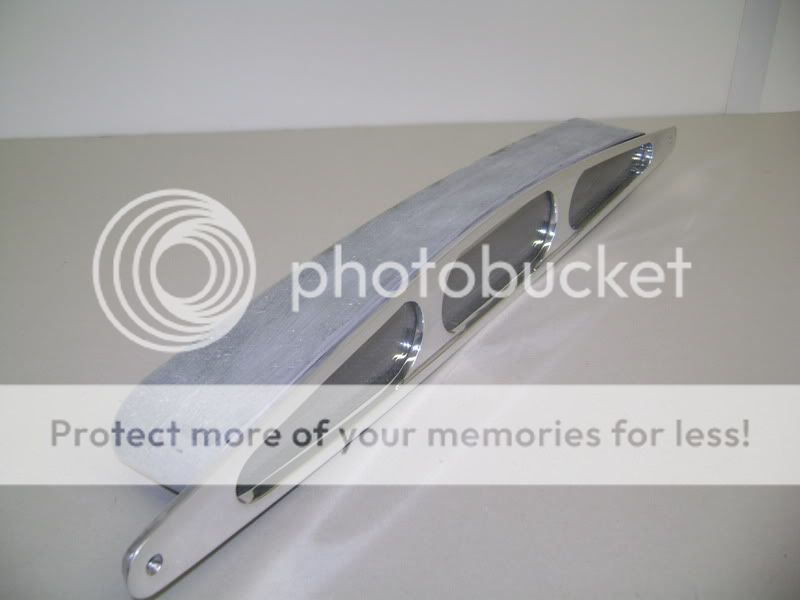

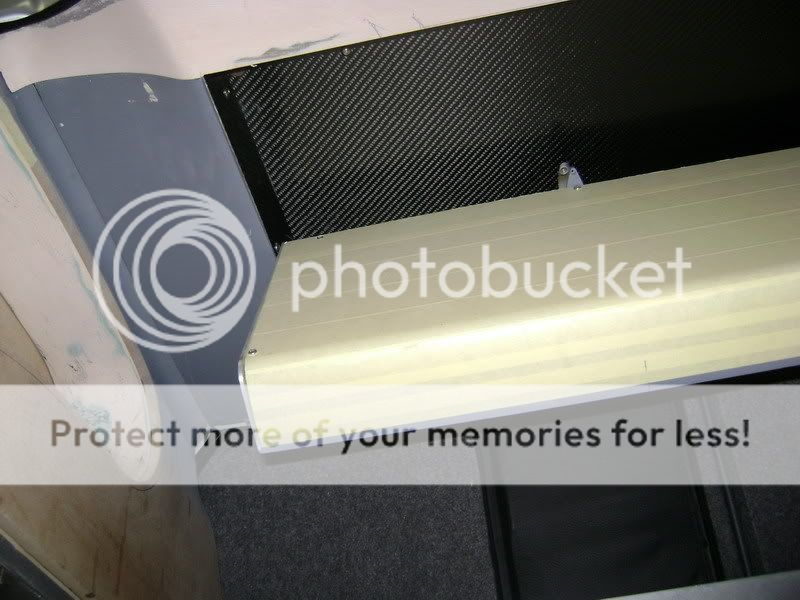

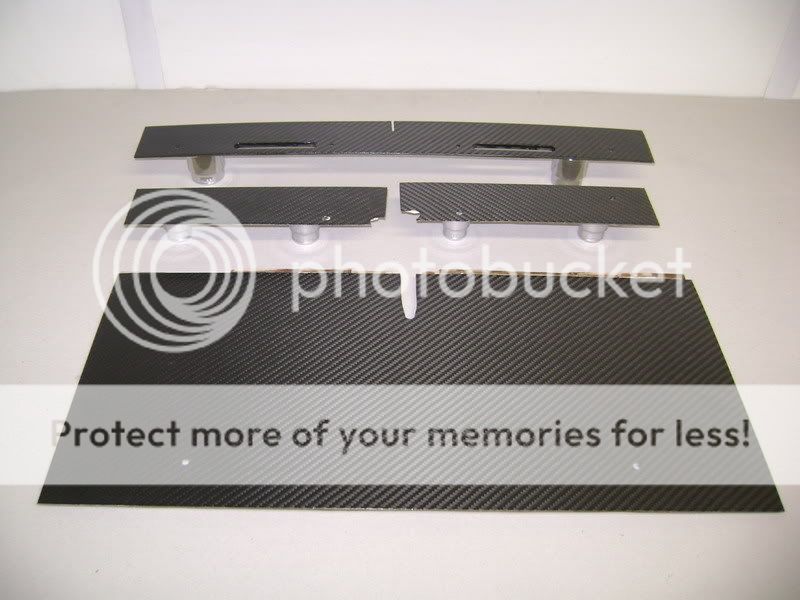

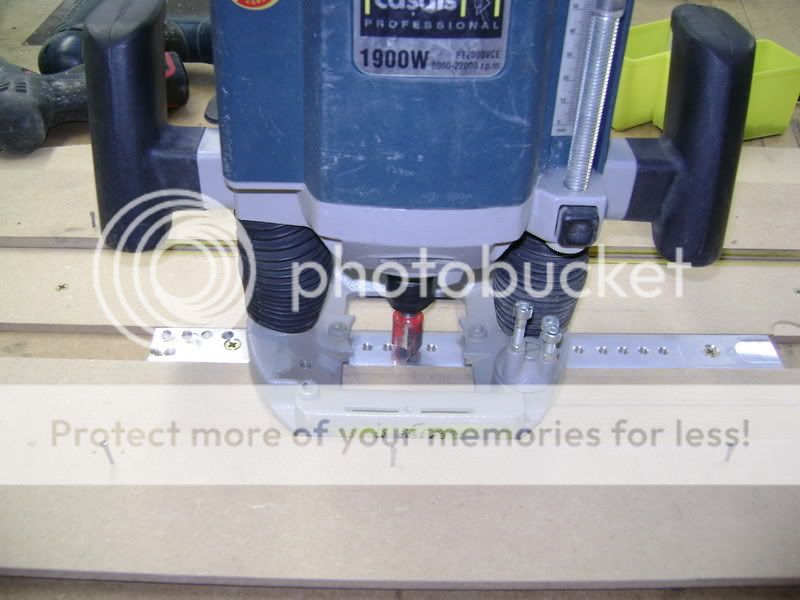

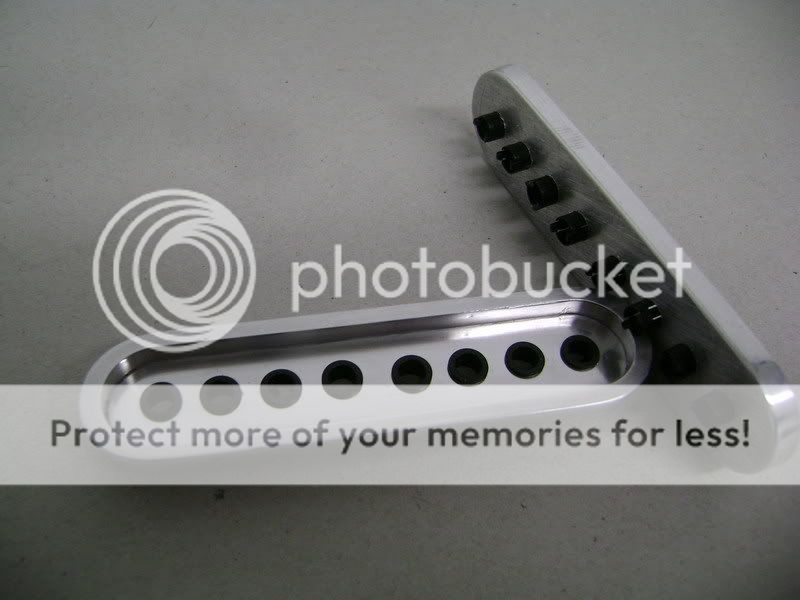

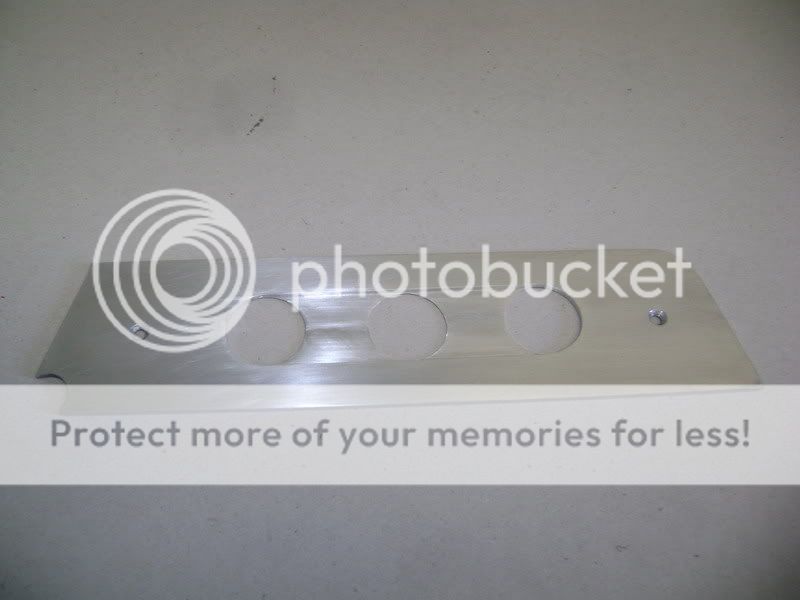

So, now the part is ready to integrate in the rest of the booth. Now i need to make a piece to mount on the backside of the aluminium part. this will be made out of carbon. I've milled the model out of a 3 by 22 mm MDF board Afterward i had to mount them back to back.

So, now the part is ready to integrate in the rest of the booth. Now i need to make a piece to mount on the backside of the aluminium part. this will be made out of carbon. I've milled the model out of a 3 by 22 mm MDF board Afterward i had to mount them back to back.

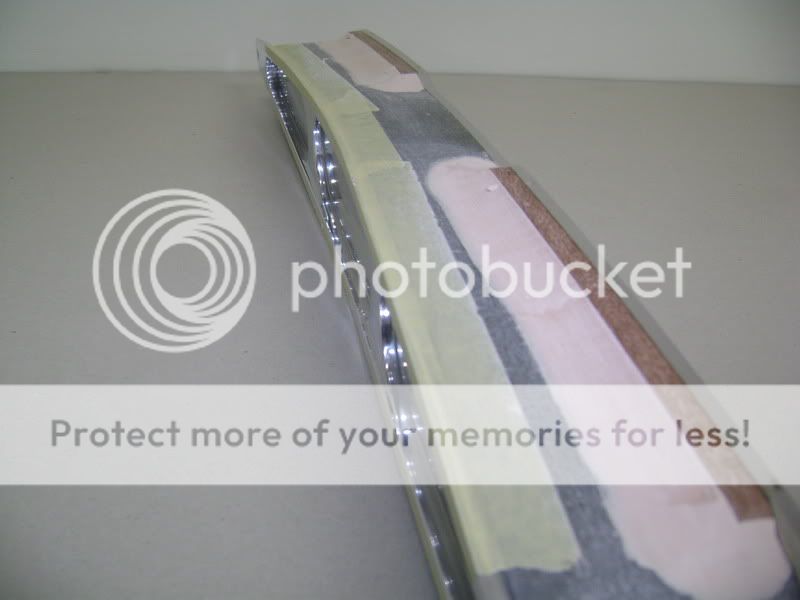

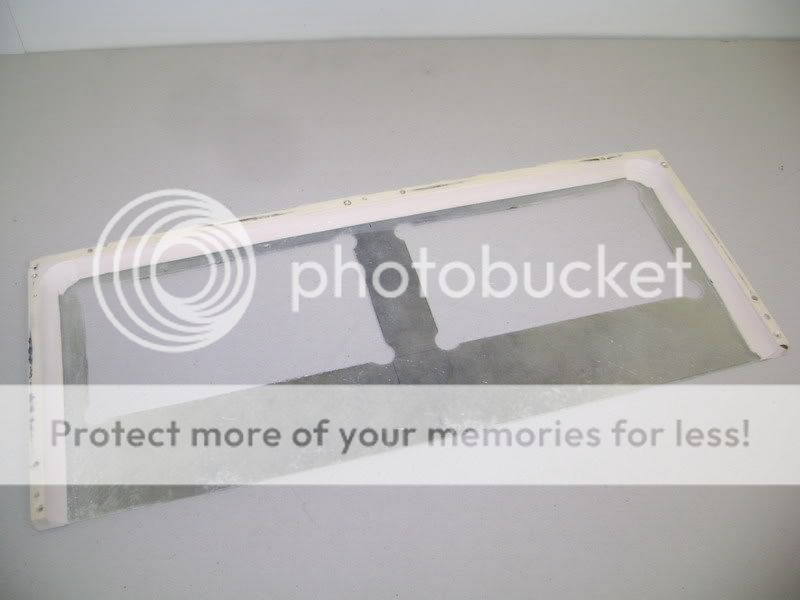

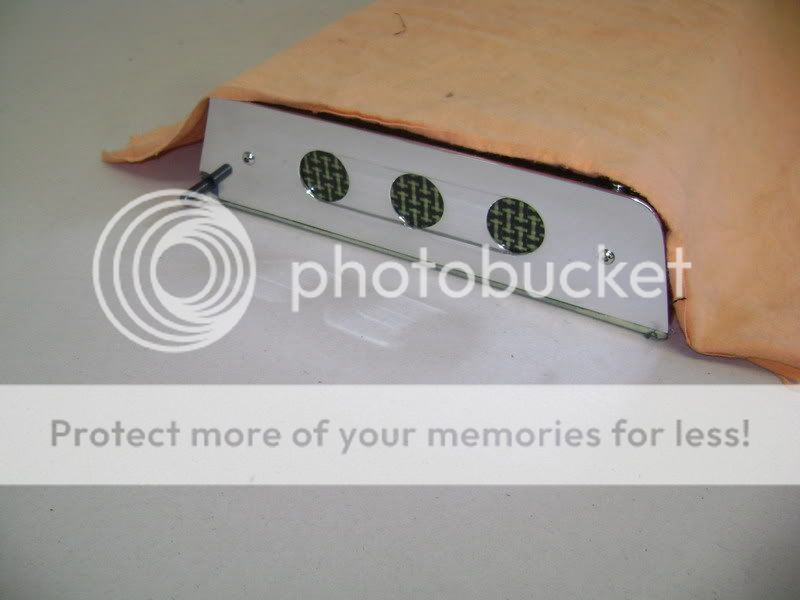

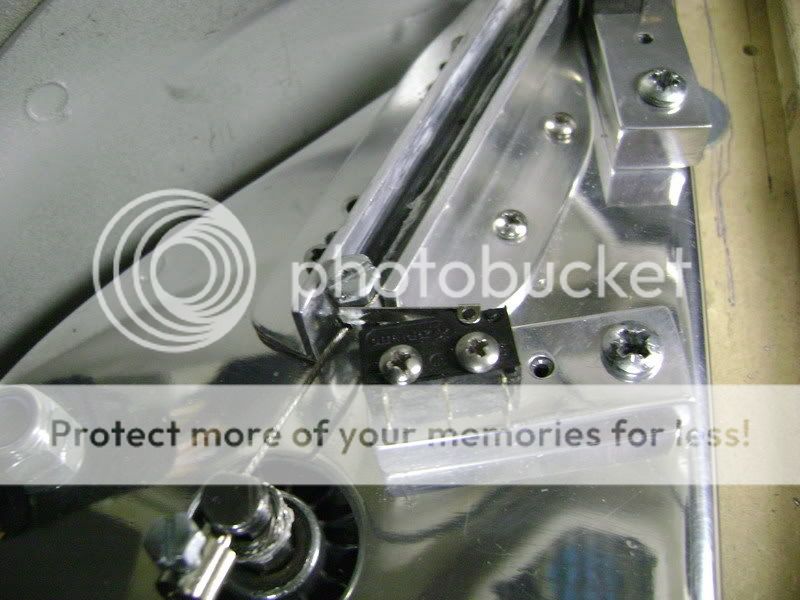

Here you can see that the part can spin.

Here you can see that the part can spin. I've used some paper tape. Afterwards i've covered it with a layer of carbon en 4 layors of polyester.

I've used some paper tape. Afterwards i've covered it with a layer of carbon en 4 layors of polyester.

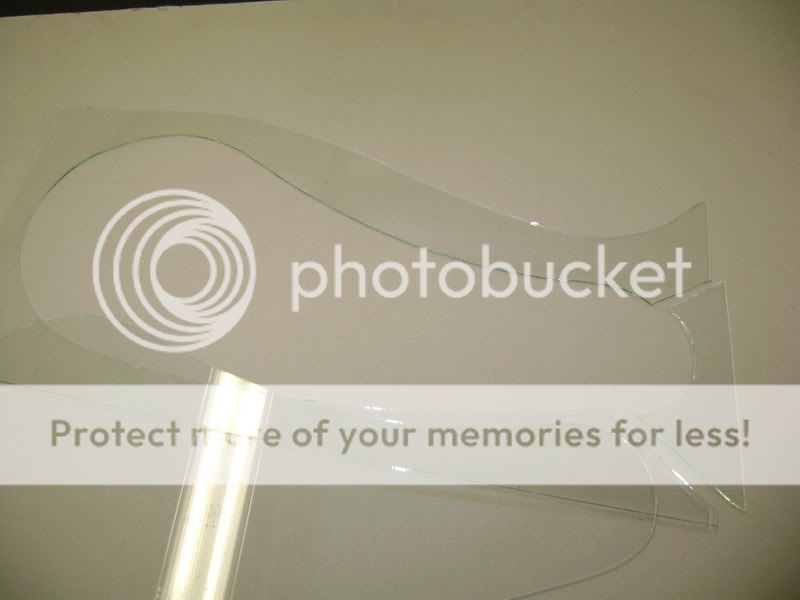

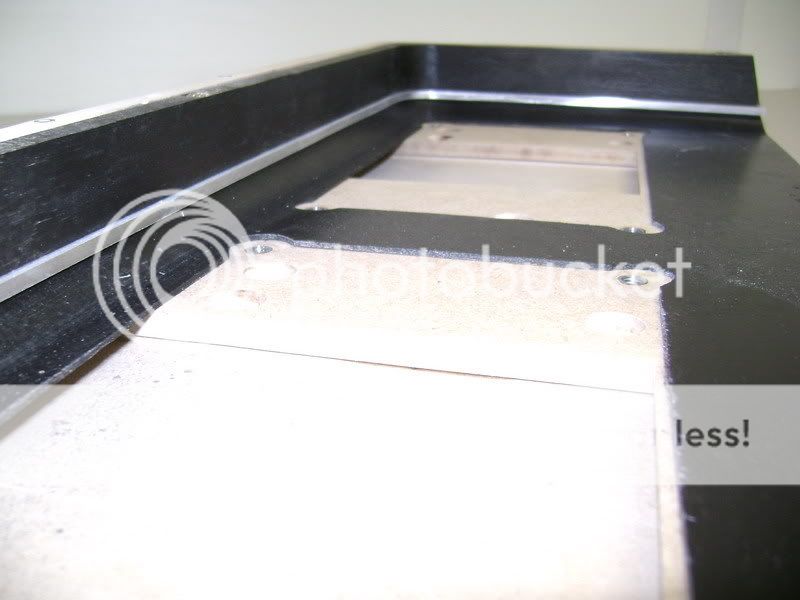

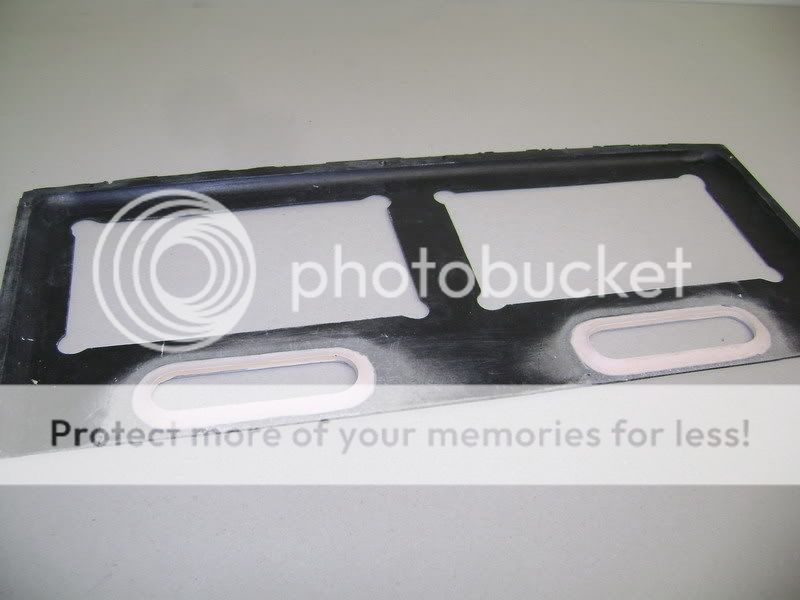

With an electrical saw i was able to remove the biggest pieces.

With an electrical saw i was able to remove the biggest pieces.  So now you see why i made the 2 holes in the board. Much easier to saw! The rest was taken out by hand.

So now you see why i made the 2 holes in the board. Much easier to saw! The rest was taken out by hand.

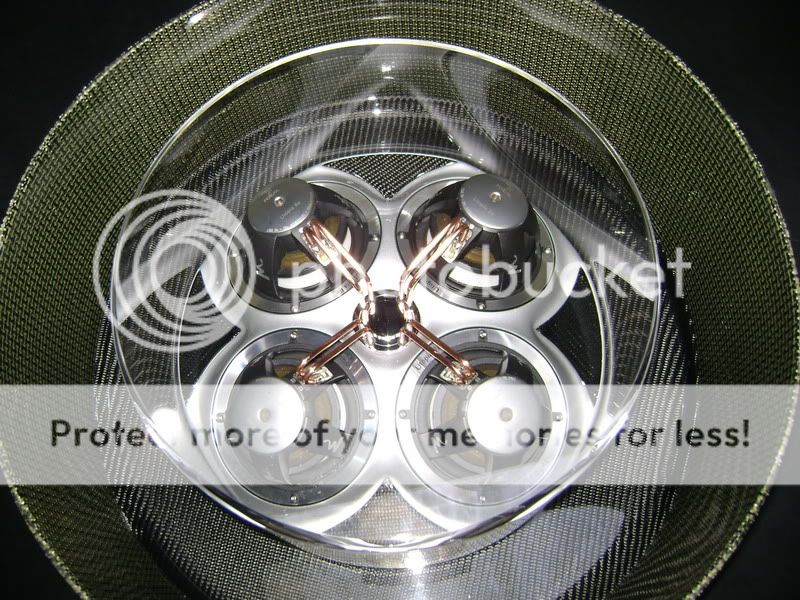

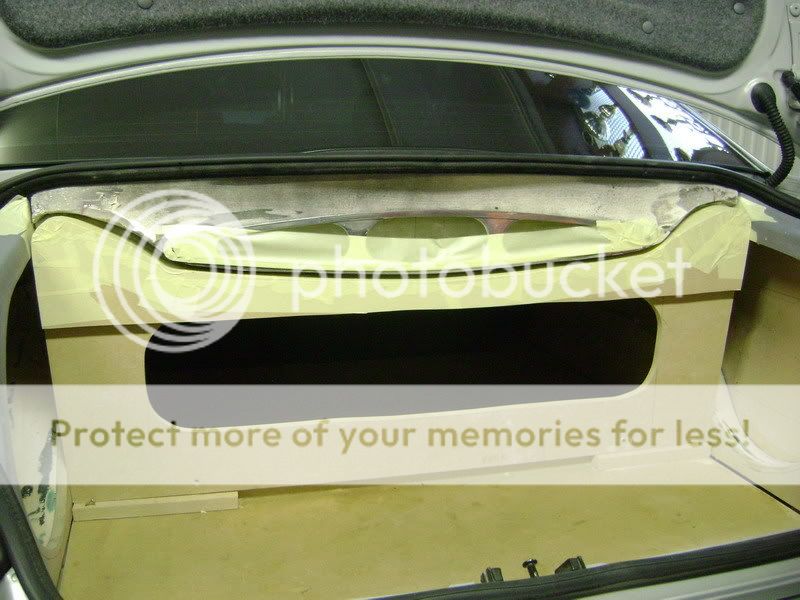

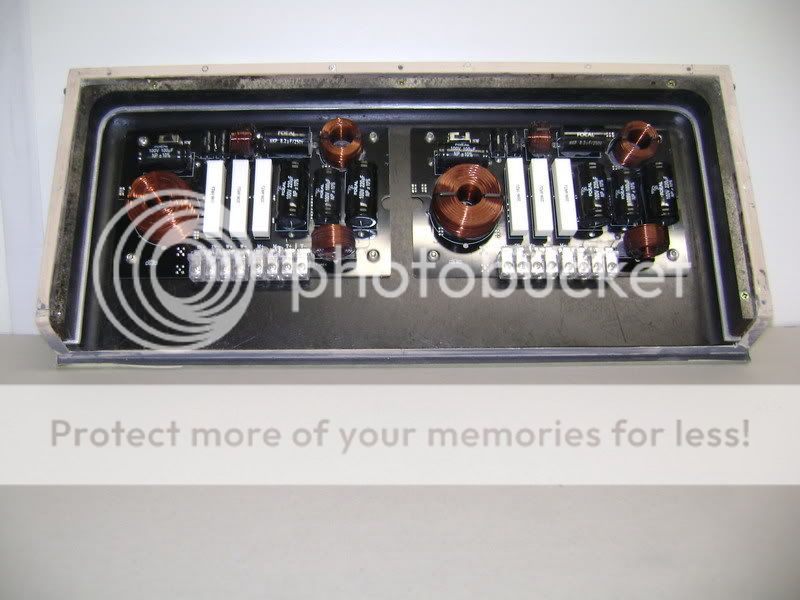

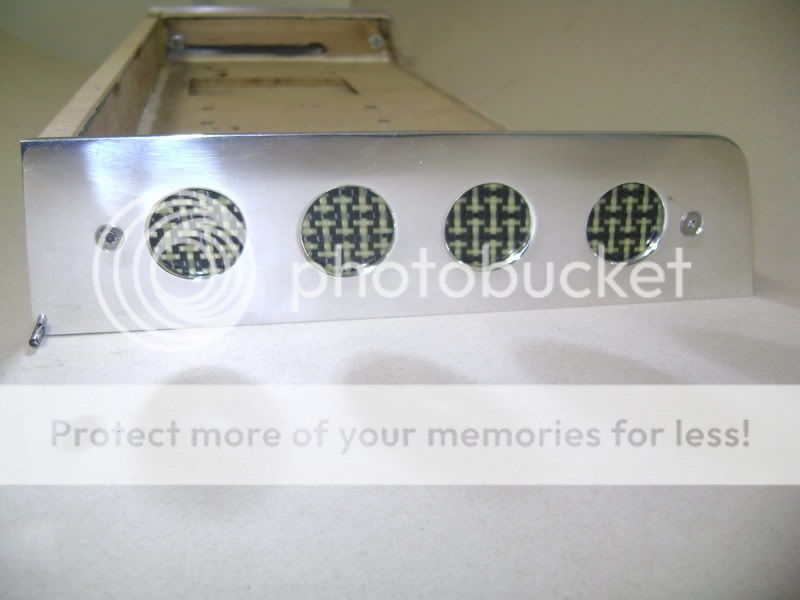

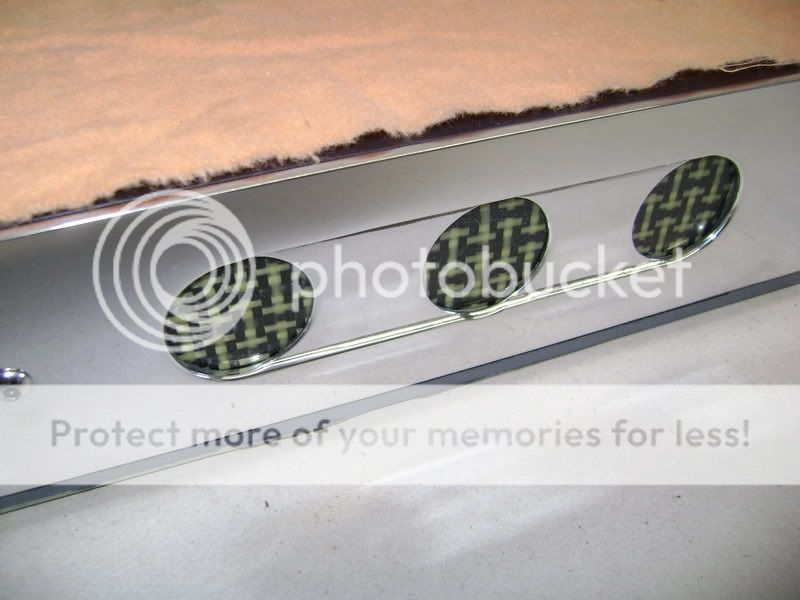

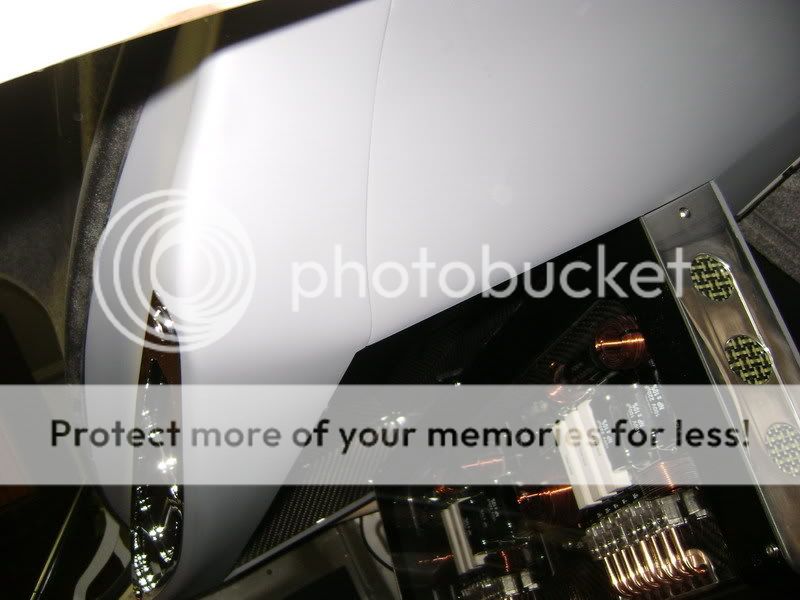

This is how everything should look like in the end.

This is how everything should look like in the end.

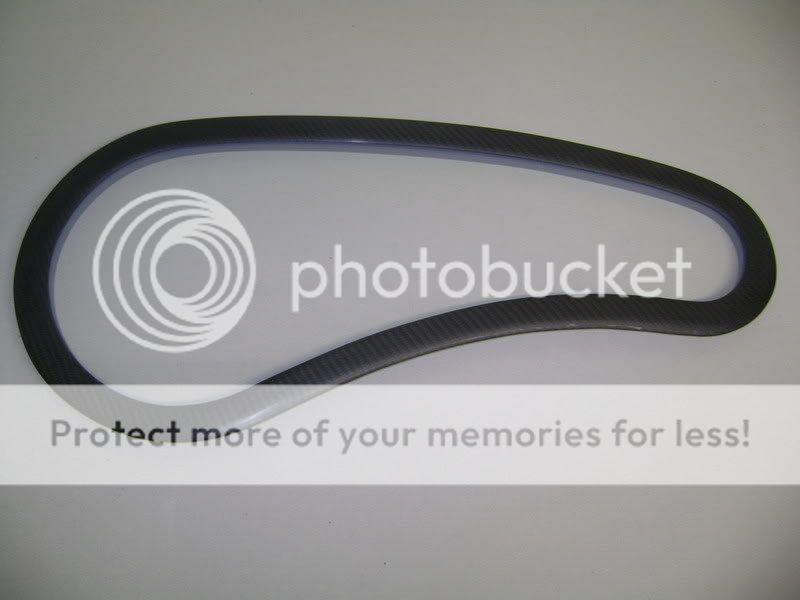

Then i've sanded the carbon frames and prepared them to get painted.

Then i've sanded the carbon frames and prepared them to get painted.

Clearcoated.

Clearcoated.

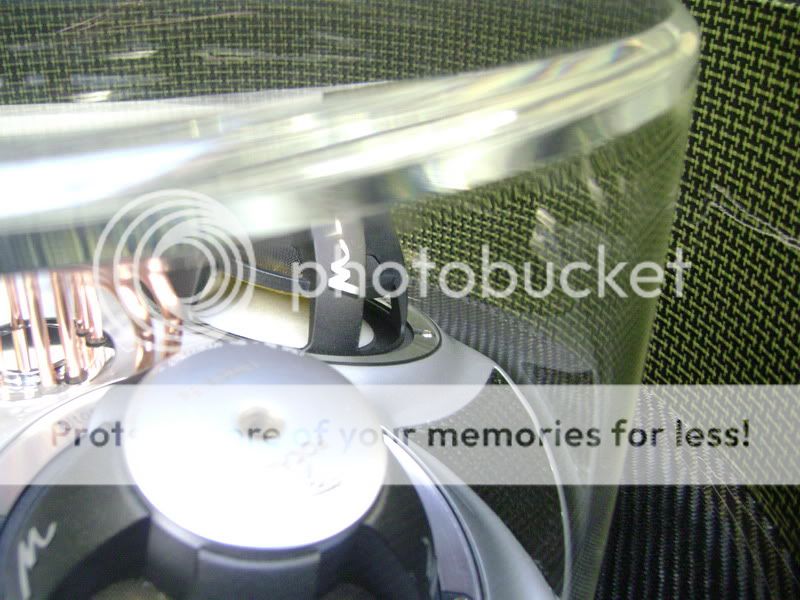

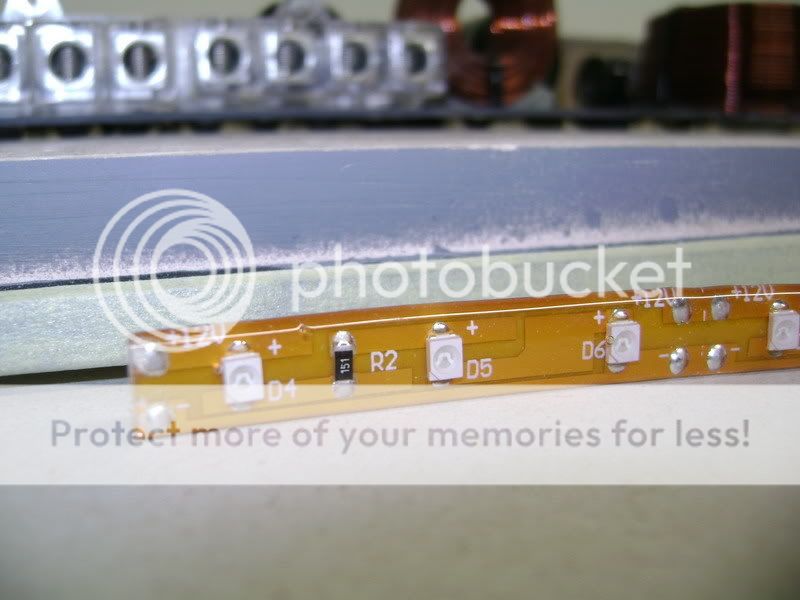

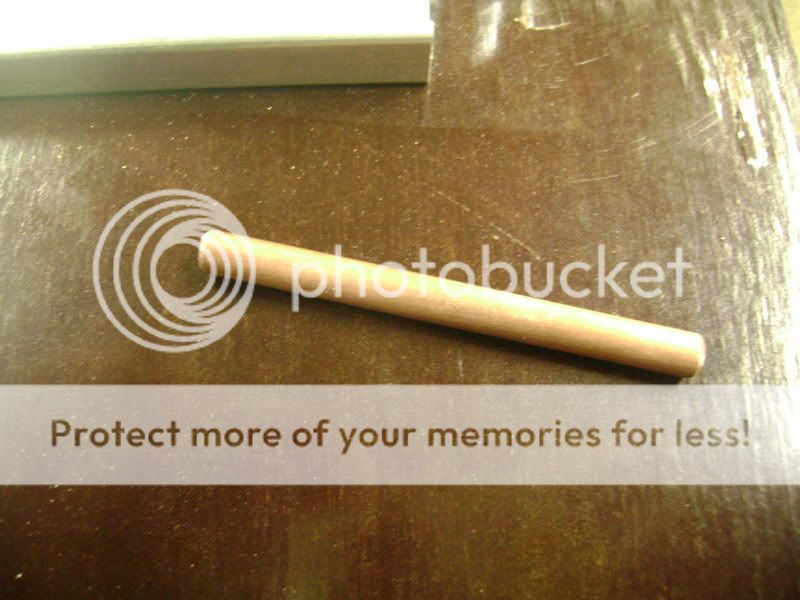

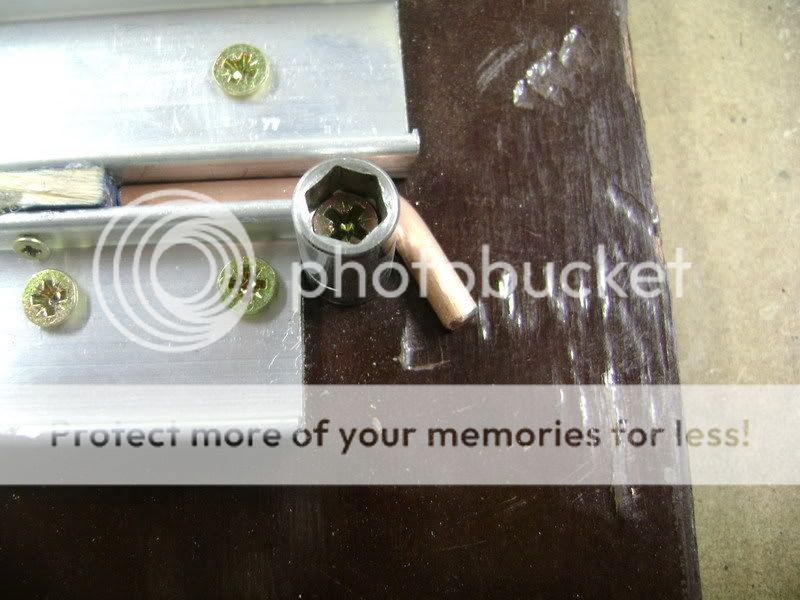

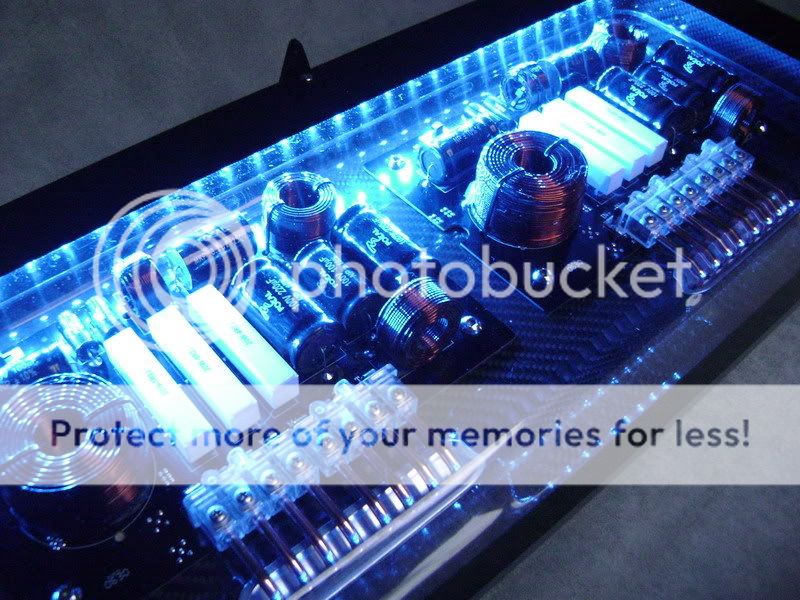

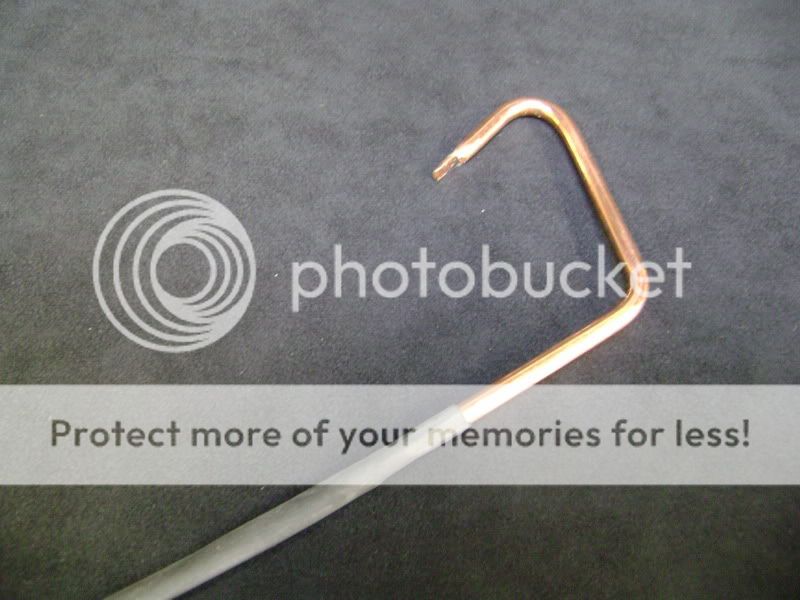

The kopper connectors have been sanded and clearcoated

The kopper connectors have been sanded and clearcoated

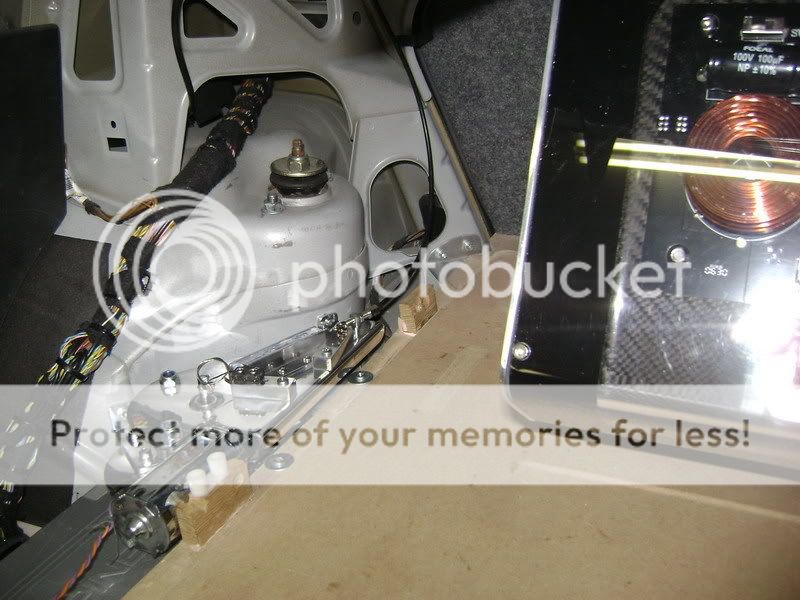

here you can see how everything works

here you can see how everything works

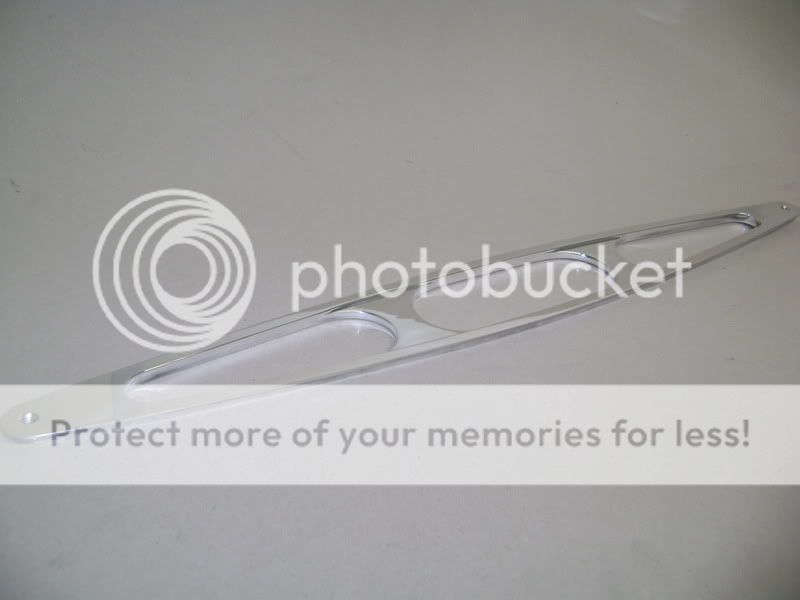

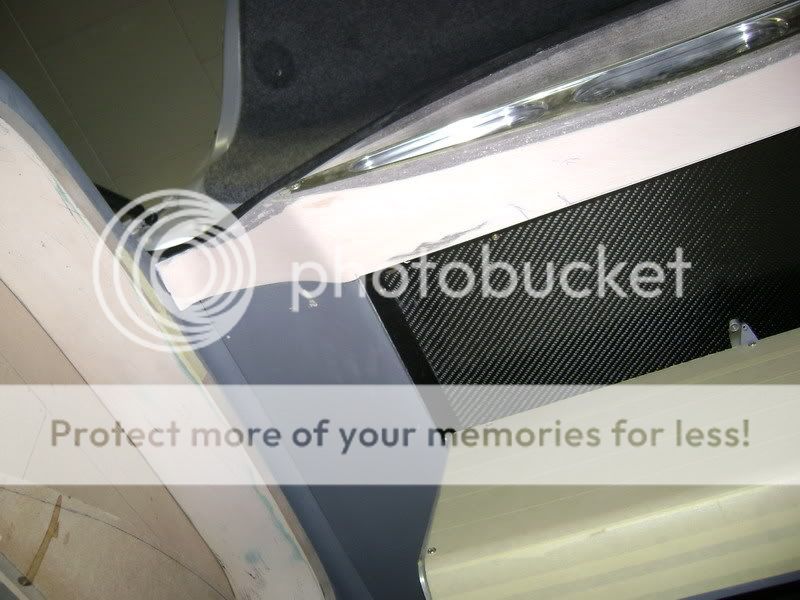

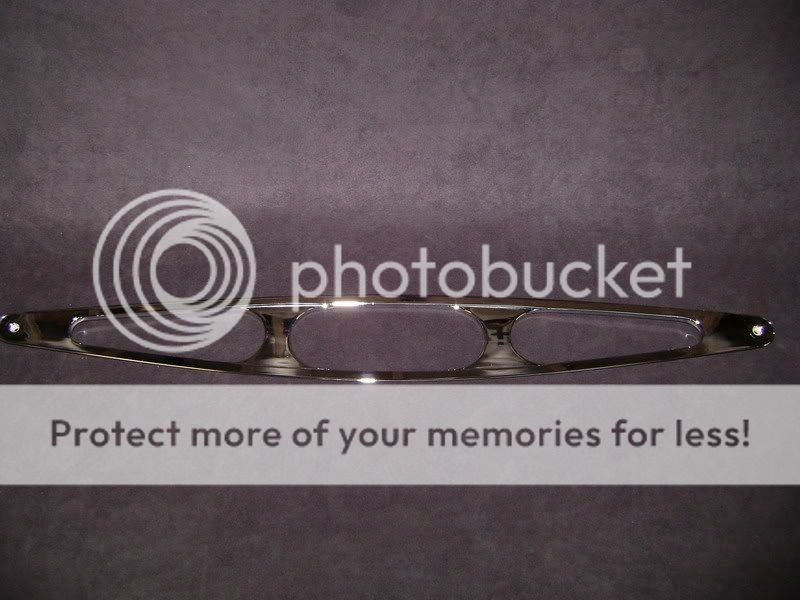

The alu plate where the copper gets through got chromed. So keeping it clean, won’t be an issue any more

The alu plate where the copper gets through got chromed. So keeping it clean, won’t be an issue any more