Posted: May 20, 2007 at 7:02 AM / IP Logged

Posted: May 21, 2007 at 11:02 AM / IP Logged

Posted: May 24, 2007 at 1:52 AM / IP Logged

Sorry, you can NOT post a reply.

This topic is closed.

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Saturday, December 20, 2025 • Copyright © 1999-2025 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Saturday, December 20, 2025 • Copyright © 1999-2025 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

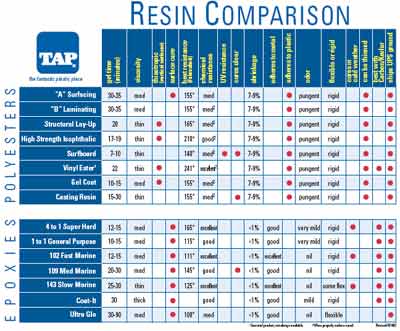

I pay $65 a gallon for this stuff from www.tapplastics.com. I worked them down to this price. This company has various pricing for various customers. All you have to do is ask. I use an expander called “micro spheres” from the same company. With this expander I can make 1 gallon of epoxy into 5 gallons, and that makes this stuff a bargain! ($49 for a 35lb. bag that will last you years). It should be noted that this expander also works with polyester. The point here though is that the price difference is insignificant.

Here are the cons

The way that this stuff is applied when you are doing cosmetic work is totally different than polyester. It requires learning new habits and techniques. Check out www.tapplastics.com for more info. The site is filled with free info and tutorials.

Instead of changing the hardener ratio to change cure time you need to change the type of hardener that you use.

You can not bond polyester products to it (but it bonds extremely well to all polyester products). So using bondo on top of it is out. I make my own bondo substitute using enough expander to make the epoxy as thick as peanut butter and a fast hardener that sets up in about 10 minutes.

If you are looking for simplicity this is not for you. If you are looking for the best product this is the ticket.

I pay $65 a gallon for this stuff from www.tapplastics.com. I worked them down to this price. This company has various pricing for various customers. All you have to do is ask. I use an expander called “micro spheres” from the same company. With this expander I can make 1 gallon of epoxy into 5 gallons, and that makes this stuff a bargain! ($49 for a 35lb. bag that will last you years). It should be noted that this expander also works with polyester. The point here though is that the price difference is insignificant.

Here are the cons

The way that this stuff is applied when you are doing cosmetic work is totally different than polyester. It requires learning new habits and techniques. Check out www.tapplastics.com for more info. The site is filled with free info and tutorials.

Instead of changing the hardener ratio to change cure time you need to change the type of hardener that you use.

You can not bond polyester products to it (but it bonds extremely well to all polyester products). So using bondo on top of it is out. I make my own bondo substitute using enough expander to make the epoxy as thick as peanut butter and a fast hardener that sets up in about 10 minutes.

If you are looking for simplicity this is not for you. If you are looking for the best product this is the ticket.