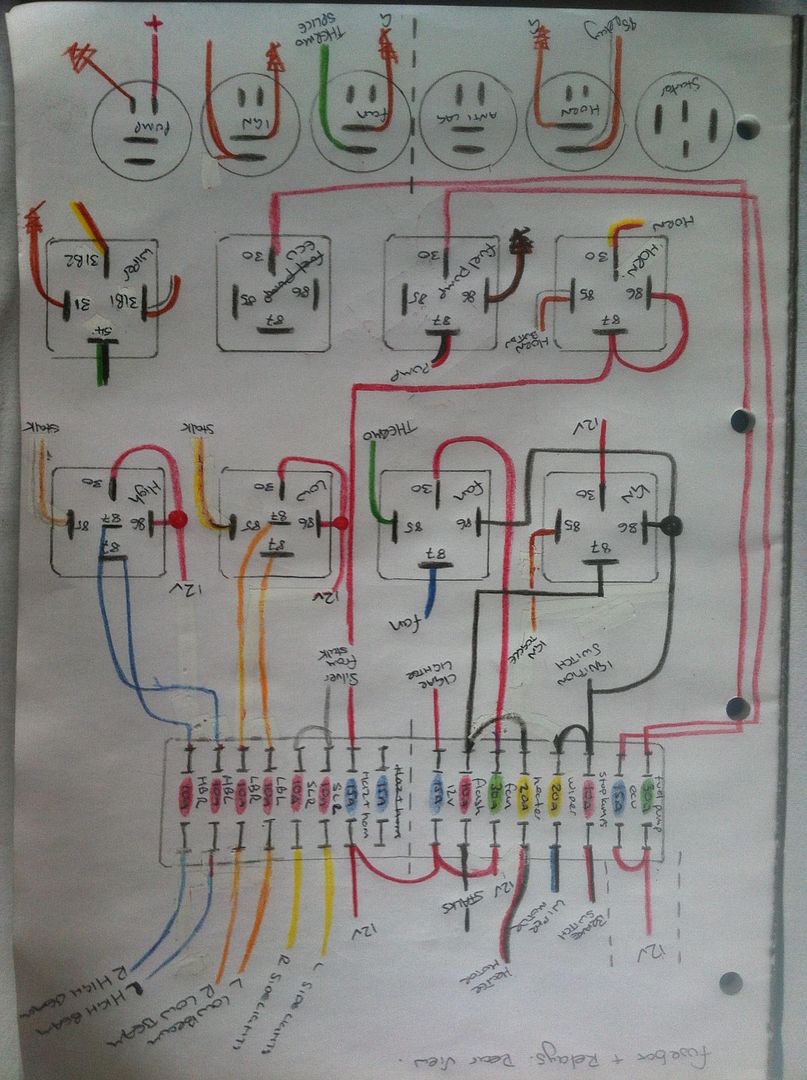

To simplify protection (fusing etc), each supply wire from a power source needs protection by a fuse (or CB etc).

The fuse shall be as close to the power source as possible/practical.

The fuse must be rated no higher than the lowest rated downstream cable and component until the next fuse. (eg, battery - 60A flink with 60A or higher cable to >=60A fusebox, then smaller fuses protect their wires and loads.)

My relay per filament was merely an example of an "electrically robust" system that survived front impacts. (And also makes headlight aiming much easier LOL.)

Since space is a premium, ditch the filament fuses and use a single fuse into the relay - but make sure cables from the relay are rated NO LESS than the (lowest rated) upstream fuse.

IMO the fan relay 86 source doesn't matter unless the IGN relay can fail and the engine keeps running.

The alternator dumps into a resistor - are you sure? That's either a heck of a big resistor, else a very small alternator!

That would only be done for a stator system & not a typical automotive alternator (or generator). Even then, a stator system is more likely to be opened rather than shorted to GND.

I think you'll find any such resistor would be a short, but for normal alternators, merely the rotor power (voltage regulator) supply would be cut or shorted to GND. But again, a kill switch should kill the engine; then the isolate switch should isolate ALL vehicle electrics from the battery.

Re your single combined kill & isolate switch. For typical vehicles I consider that unsafe.

Since that switch must be in the +12V line between the

battery & alternator and the rest of the vehicle, assuming it's not near the battery terminal it's a lot of

hot wiring that could short in and accident or fire.

Hence for accident & fire safety reasons,

remote isolation switches should (or must!) be in battery's GND circuit. But that requires a separate circuit for the engine kill, though it does isolate the alternator from the battery, and even protects against panel/body short direct to the +ve battery terminal.

As on motorbikes, the engine kill switch merely kills the engine and leaves everything else connected (lights etc).

I know of the odd competition that specifies a single engine kill and battery isolate switch. I expect they won't change that IMO stupid and irresponsible stipulation until someone dies...

GND or +12V switching of relays...?

In principle either can be used.

In practice, hot or +12V switching is preferred so that a short won't turn or keep relays on - eg, water/moisture to GND, frayed wires, etc. GND switching is otherwise preferred so save one wire or more, and to enable simple joining of alternate inputs/switches.

And of course, the FPR is controlled by the ECU (else alternator or spark etc) and not merely a toggle switch...

Safety - yeah, I only just clicked that it was an old Escort. I'd be ditching its electrics too!

And hopefully they don't have the old (TC model?) Cortina fault where the fuel line pops out of the carby and sprays the engine bay. The resulting heat was nice on cold days, but other vehicles fit heaters rather than flame engine bays. But I liked the design as an example of why you do NOT use fuel pump control to kill engines - at least for carbied cars - and hence

never oil-pressure controlled fuel pumps. (If the pistons also holed because of the leaning mixture, the relevance to EFI engines is almost complete.)

Printable version

Printable version