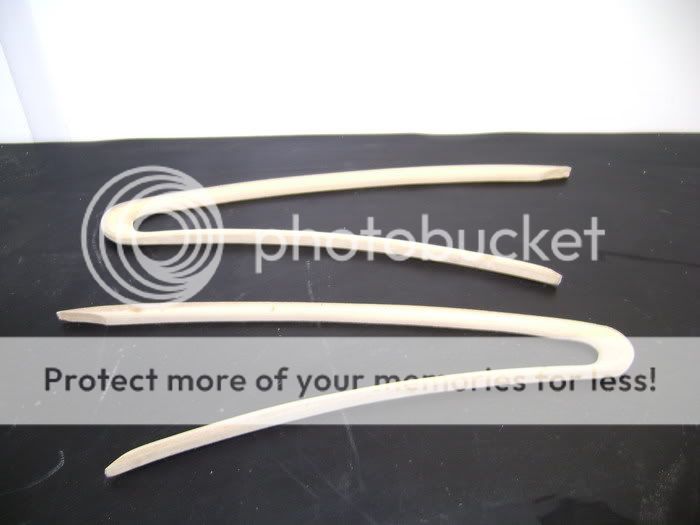

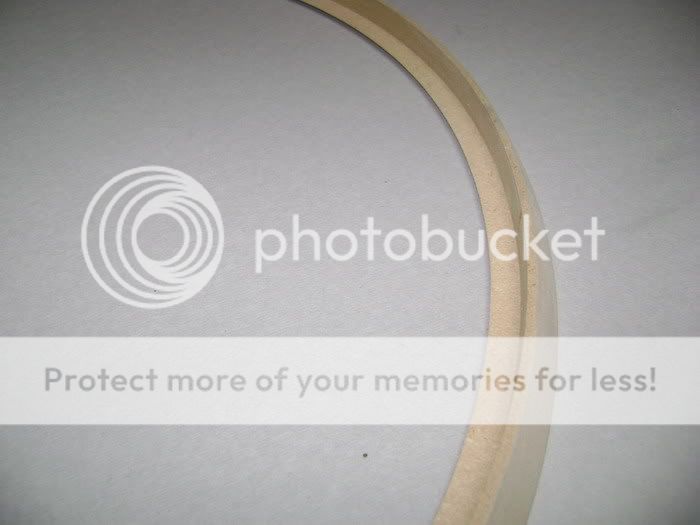

Took the uppermill and started the outer-ring.

Started to begin polishing. Is a heck of a job, people who polished with heavy machinery before know...

It's kinda hard to do this without the brushes hacking into the alu..

I did this:

Screw the piece on a piece of wood that you can hold on tight.

1) you won't burn ya fingers/hands on the alu

2) the brush can't bite himself into sth

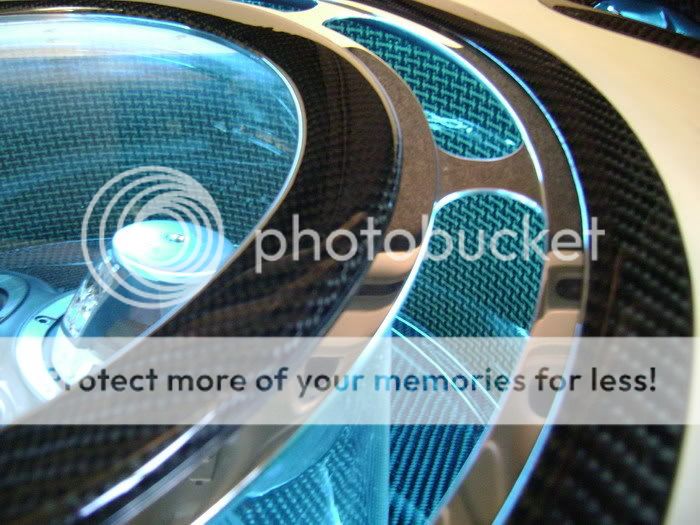

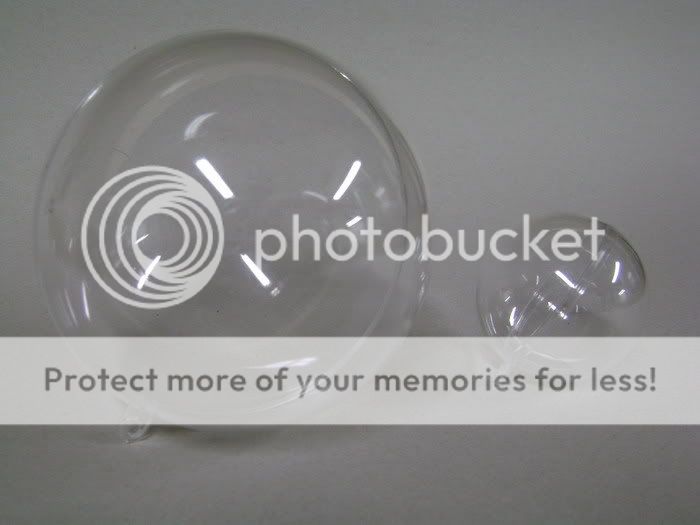

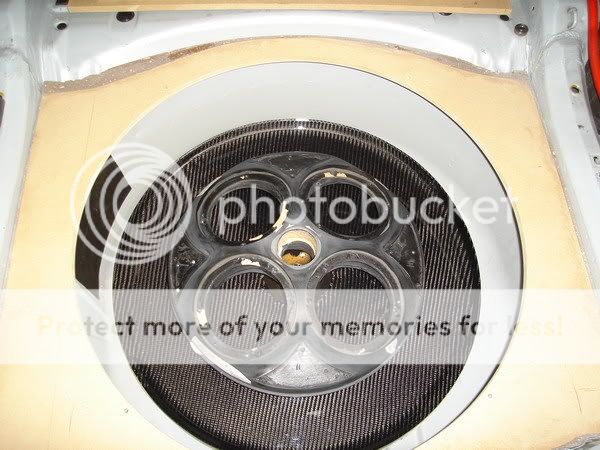

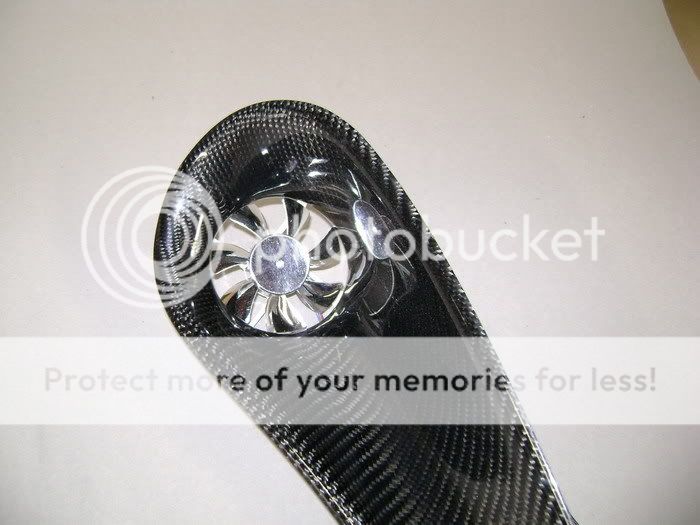

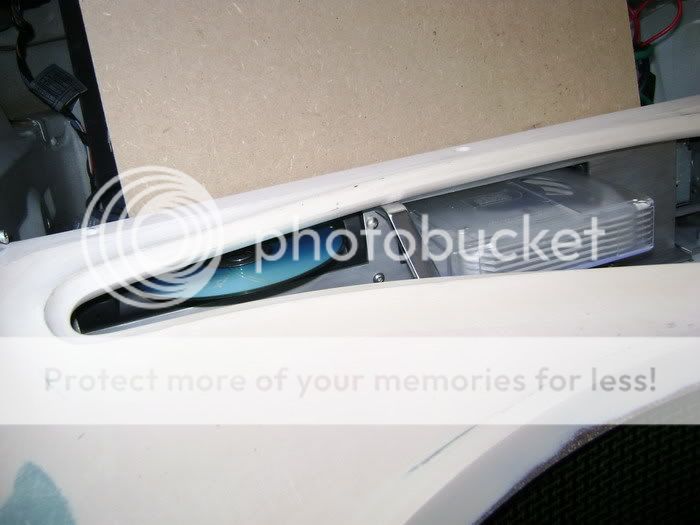

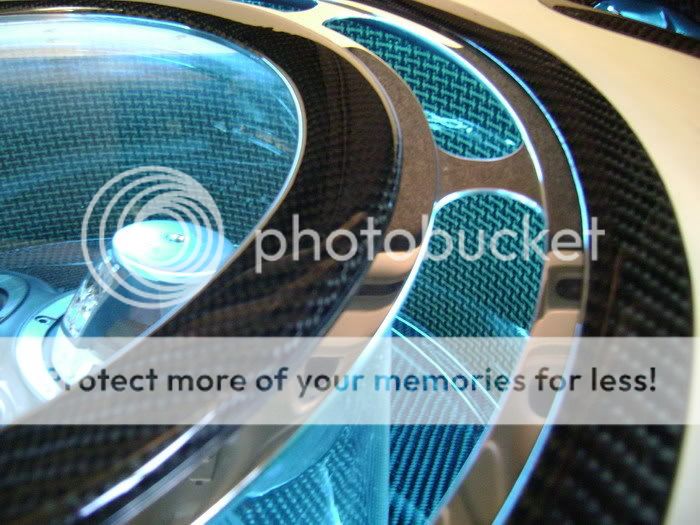

As you can see, the whoel sub part is see-able and yet, it's covered with real glass I can clean as much as he wants, without making scratches.

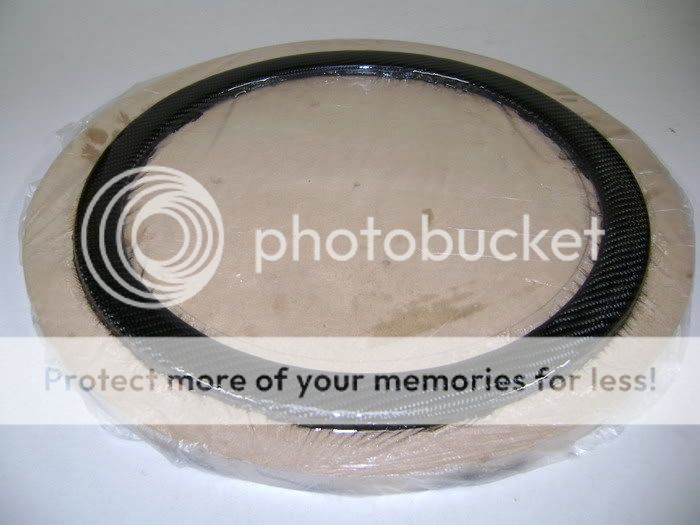

The nice thing about this grille, is that I made it with a simple milling tool. This is the proof everyone can make something really nice, with non-expensive equipment.

The grill is almost complete. for now, no Focal Logo's anymore

althought...

The next work on the list is for next days, maybe weeks.

The actuator, that bringt the amplifier to life, will get a nice place.

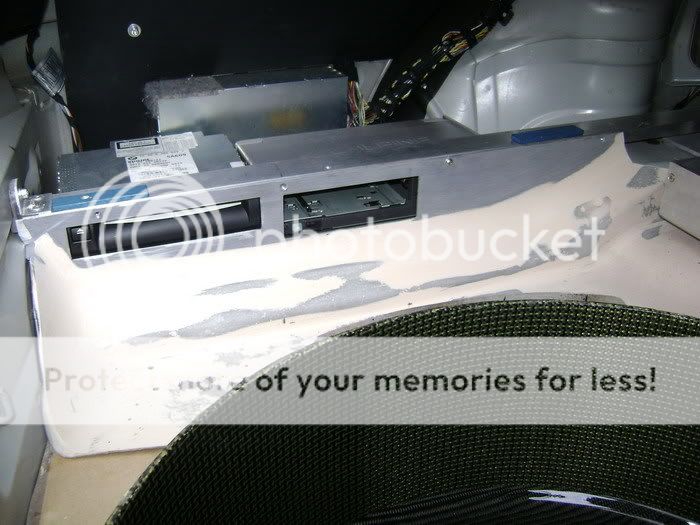

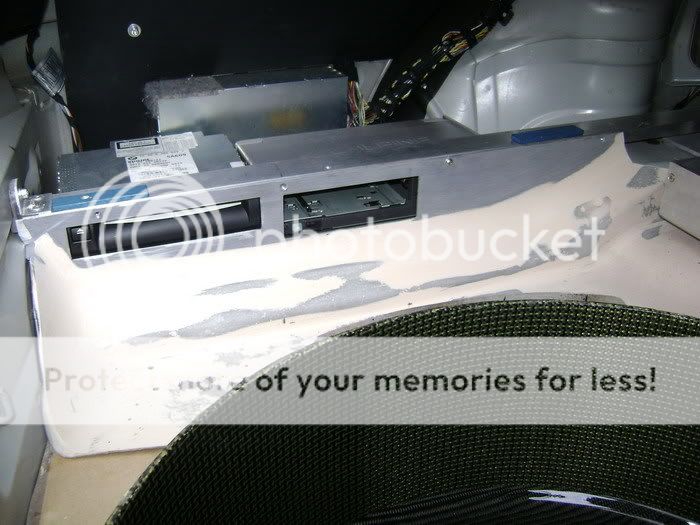

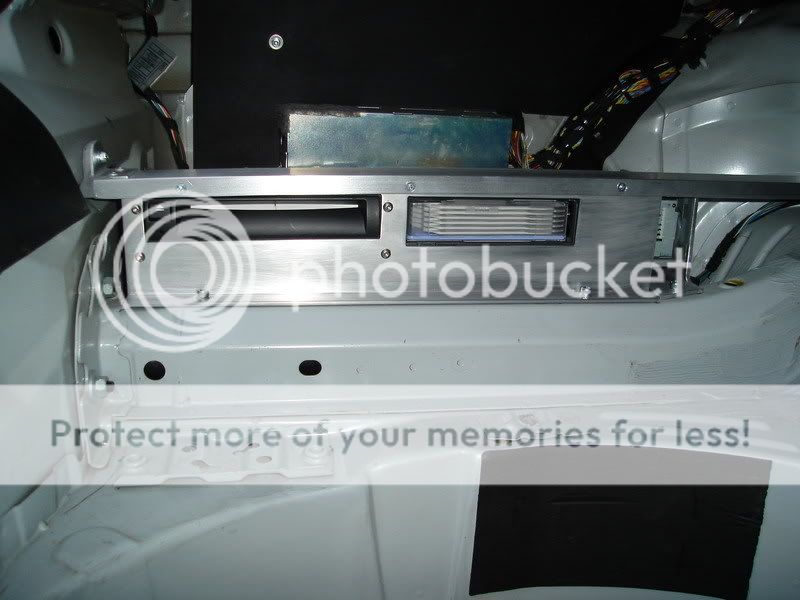

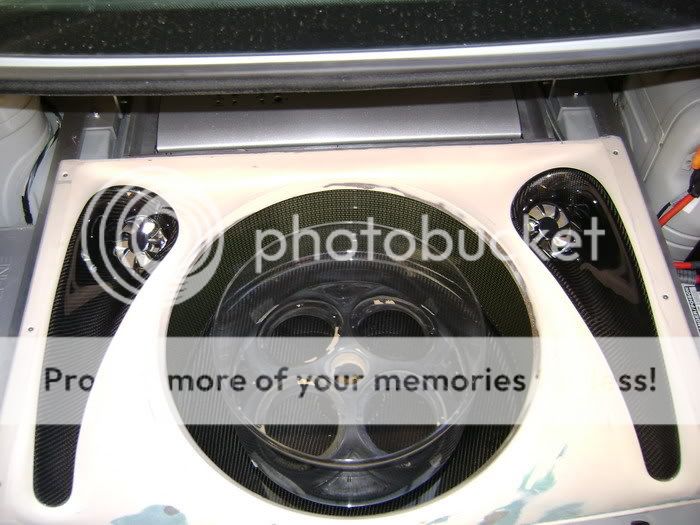

For those who forgot, this is how the motor was placed.

This was only to see if the thing worked like I wanted.

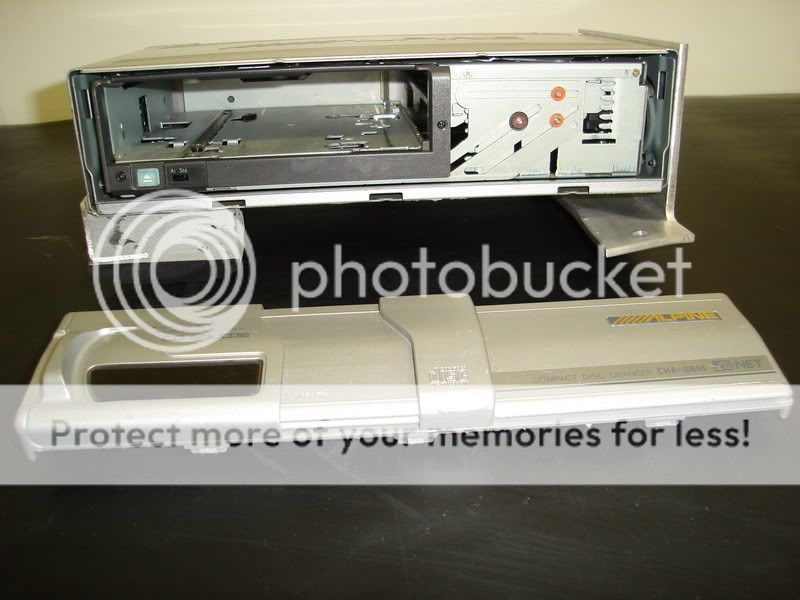

The meaning is, if you take the left carbon piece away, you see the motor and the cd-changer. If I wanted to show this, it must be made SHOWABLE

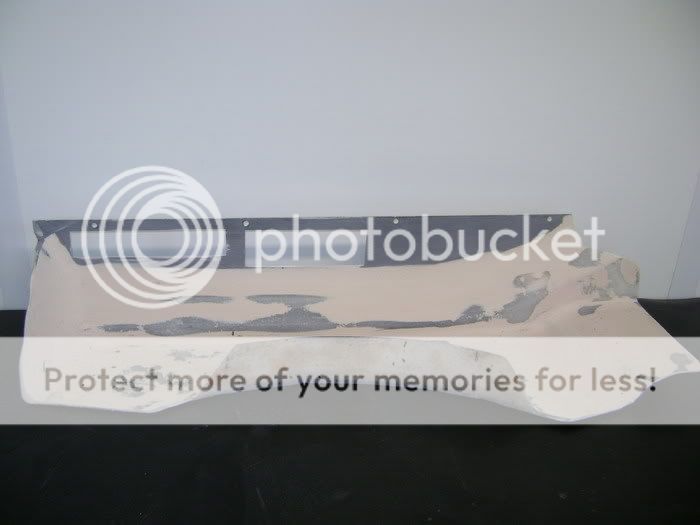

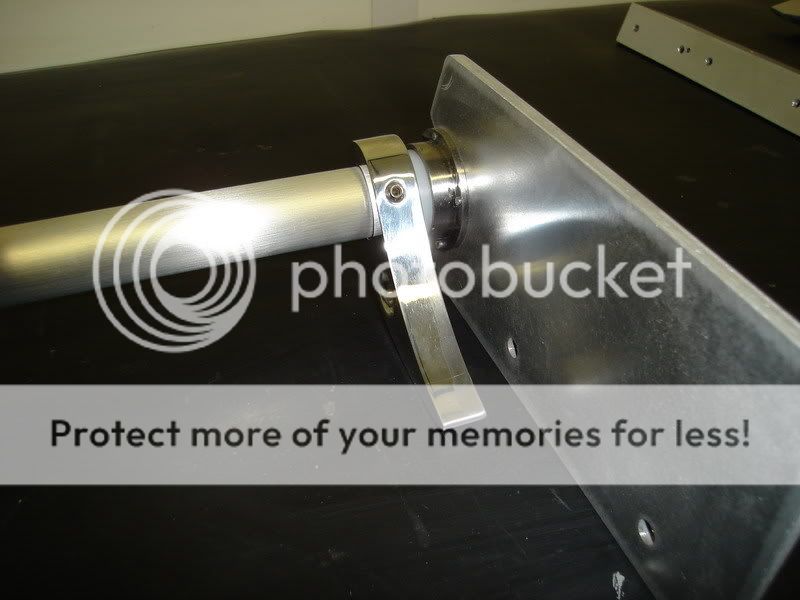

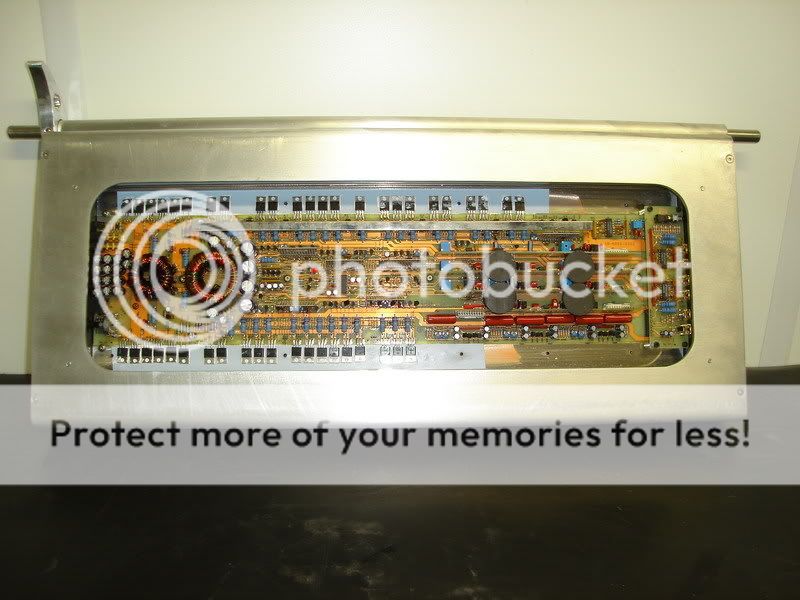

Then, I put the actuartor on a alu plate of 4mm thick.

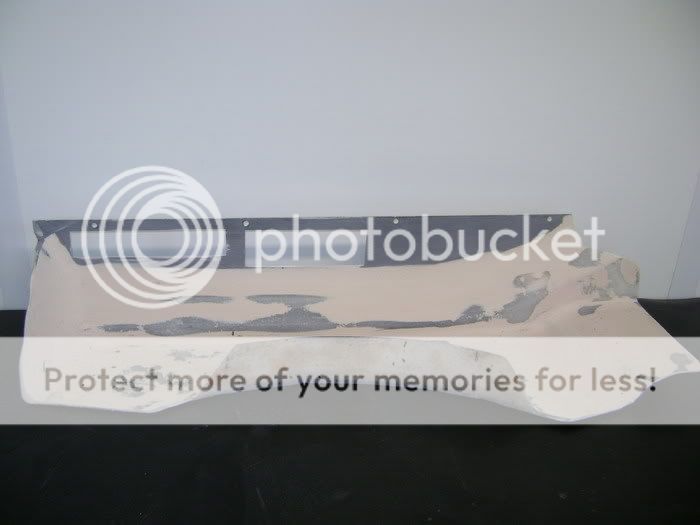

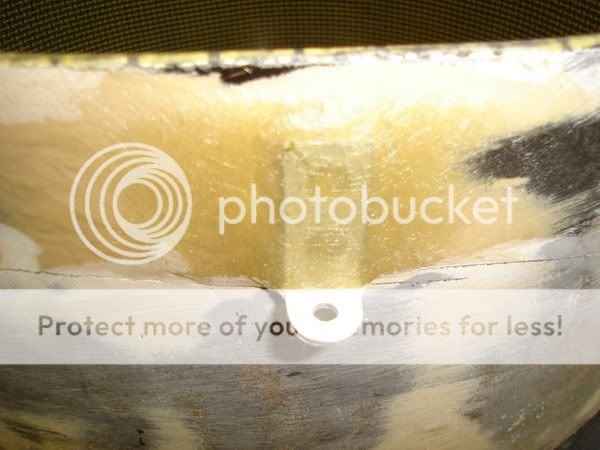

The fiberglassed part where the motor will be put on tight, is as good as ready.

I sprayed this black. Those who read all thread, now what that means .

This will be the alu plated where the motor will locked on.

As you can see, I made 4 big wholes in it. Under these, put a carbonkevlar plate. The look will be a little bit better I think.

Also you can see I made a alu piece with M5 screws. Here will be a "bar" in connection with the amp.

I took everything on a trip to polish-land.

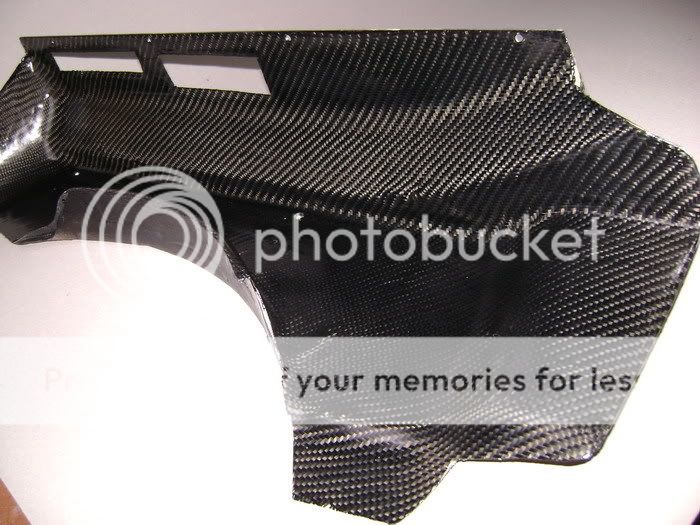

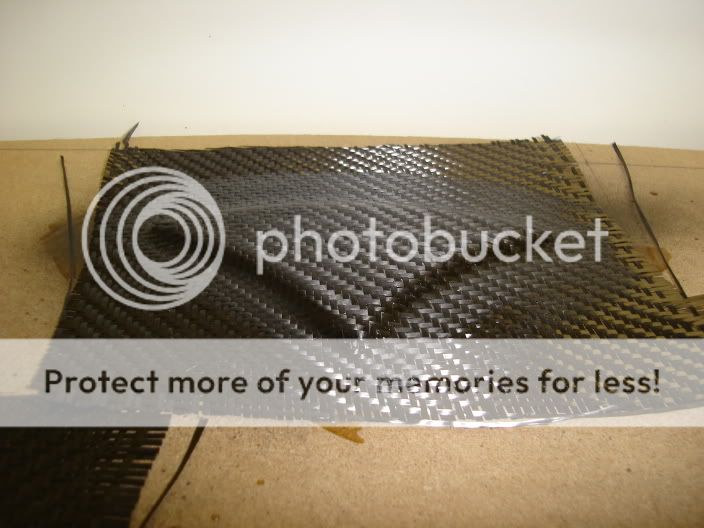

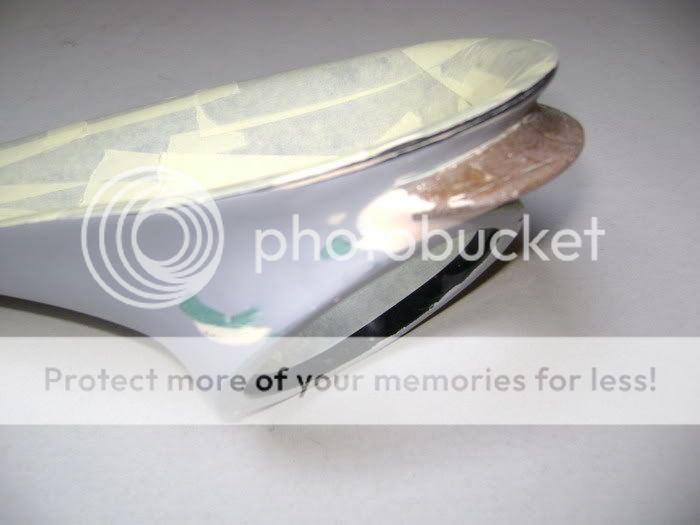

The fiberglass part that comes under the motor, is already covered in a layer of carbon... needs some more epoxy.

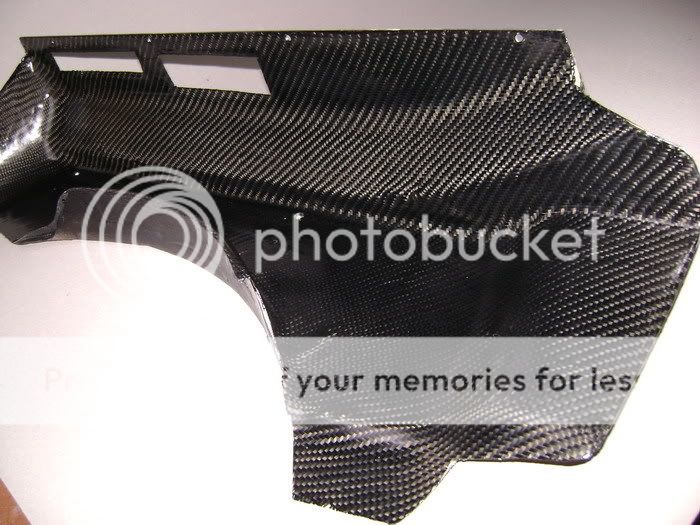

Not simple to cover it in carbon, but it worked.

Couple of layers of epoxy are needed, and then rubb the whole piece, while working on the sides..

Damn, this piece looks great, but you're not going to see much of it .

The CF piece, to put the motor on is ready... I did some long long long rubbing, but it was worth the effort.

Printable version

Printable version

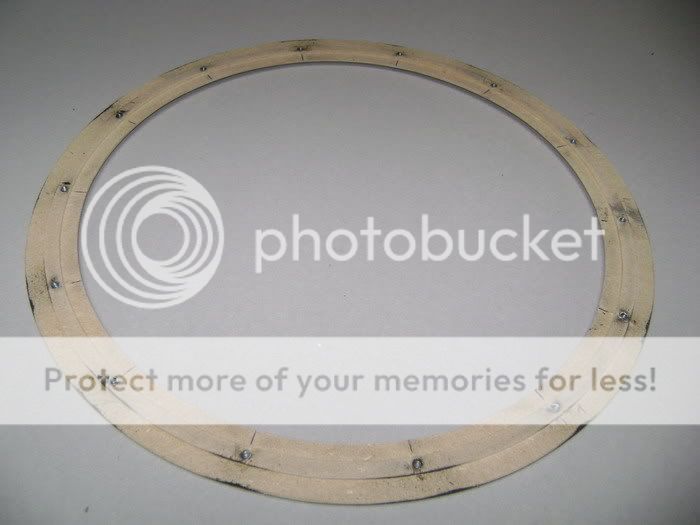

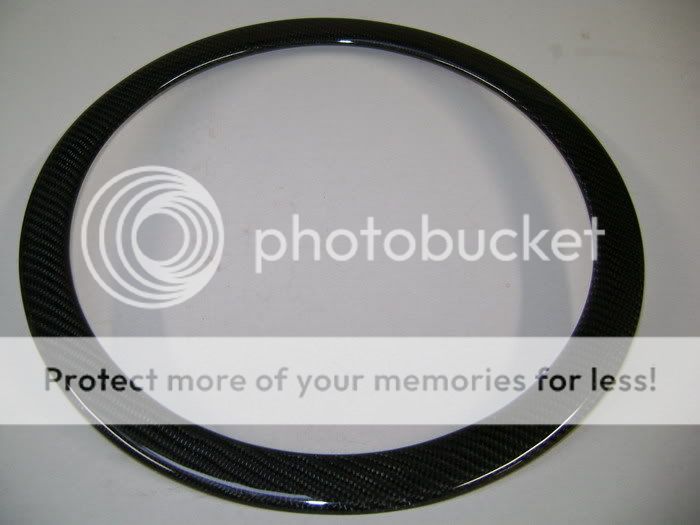

milled some rings to put the woofers in.

milled some rings to put the woofers in.

Here a picture of the bottomside, where he made wholes , to let the sound flow outside.

Here a picture of the bottomside, where he made wholes , to let the sound flow outside.

The next thing on the list is something very difficult.The connections of the speakers he'll make in copper, of 5mm thickness.Cables are so boring

The next thing on the list is something very difficult.The connections of the speakers he'll make in copper, of 5mm thickness.Cables are so boring

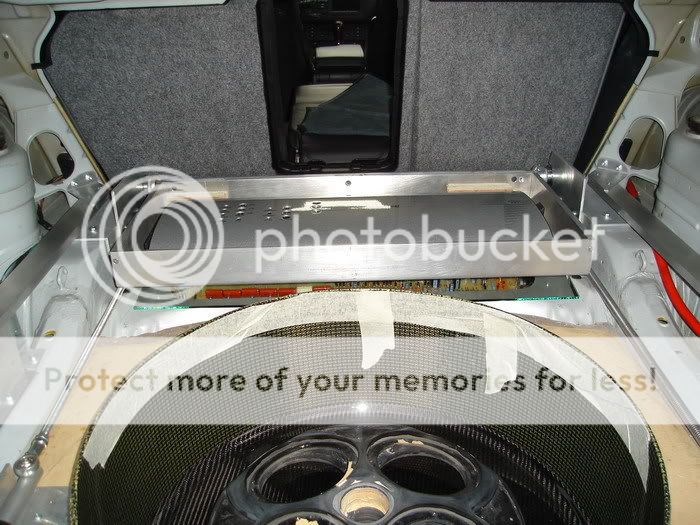

put some movement in the amp.

put some movement in the amp.

Here's a picture from the front. You can see a V where everythings slides into.

Here's a picture from the front. You can see a V where everythings slides into. Then he fiberglassed a little alu piece that is fastened bigtime.

Then he fiberglassed a little alu piece that is fastened bigtime.

In the whole those things are layed into, fiberglassed a firm alu bridge, and there the backside slides into.

In the whole those things are layed into, fiberglassed a firm alu bridge, and there the backside slides into.

On the picture, you can see he miled a little ditch.

On the picture, you can see he miled a little ditch.

this is the bottomside. You see I made some screwbusses in it.

this is the bottomside. You see I made some screwbusses in it.

The meaning is, if you take the left carbon piece away, you see the motor and the cd-changer. If I wanted to show this, it must be made SHOWABLE

The meaning is, if you take the left carbon piece away, you see the motor and the cd-changer. If I wanted to show this, it must be made SHOWABLE