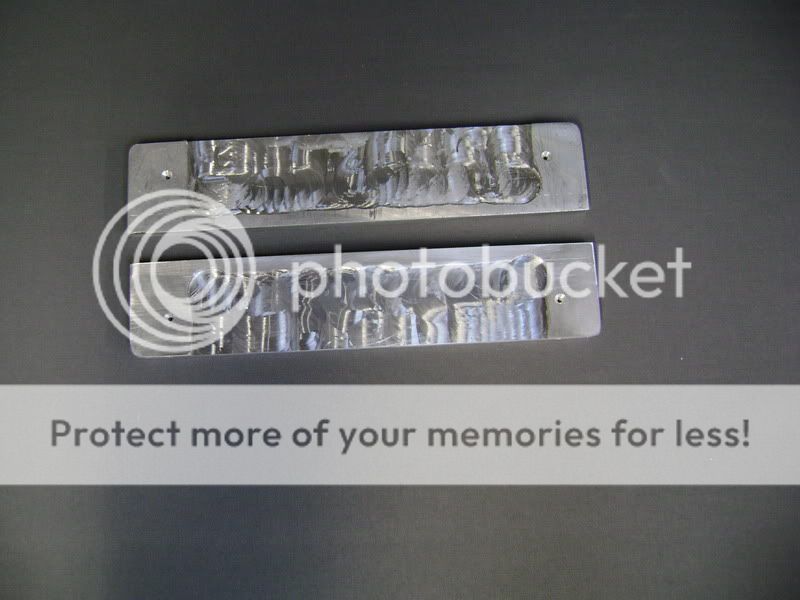

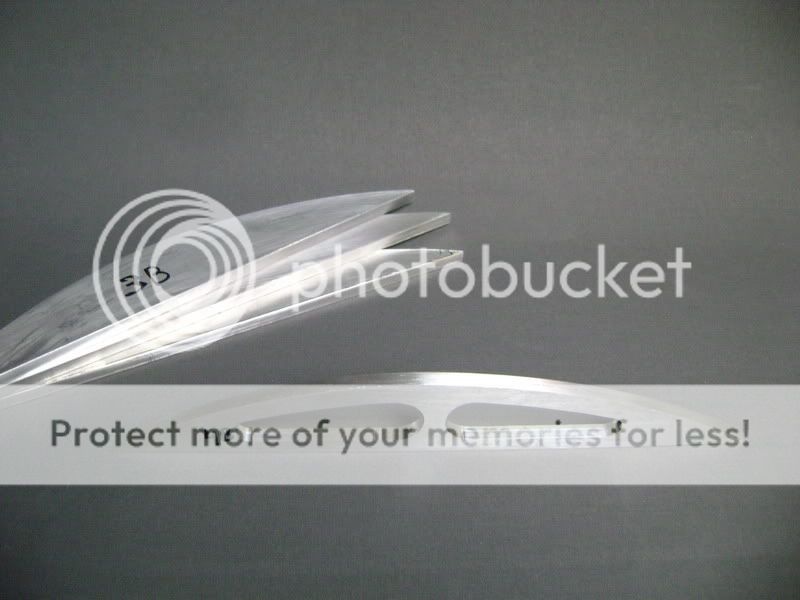

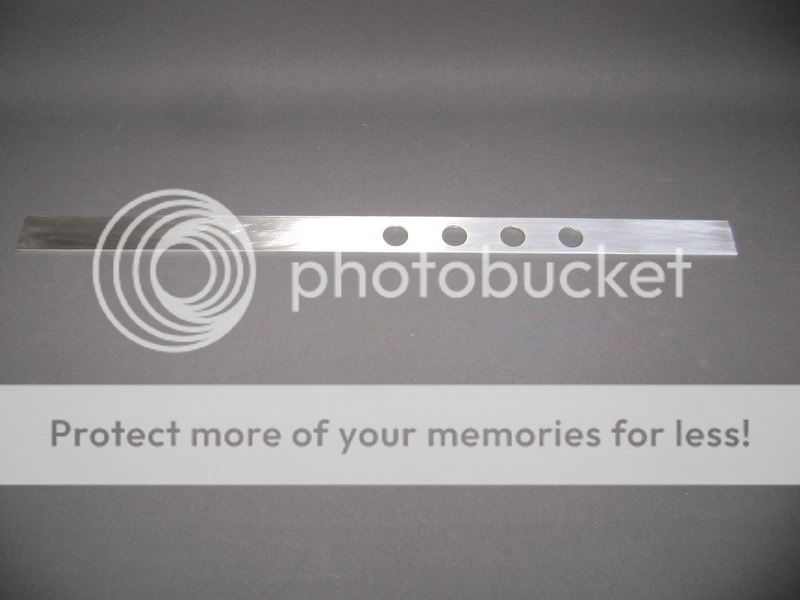

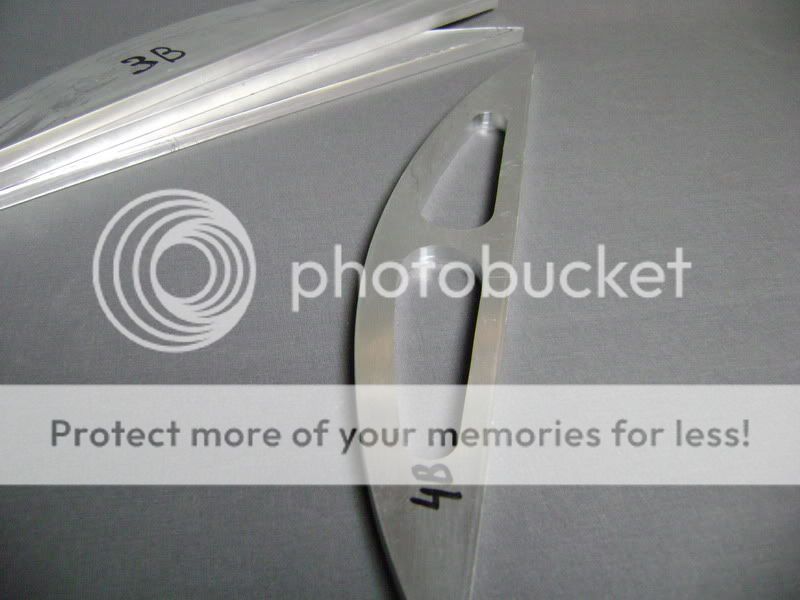

I made 4 aluminum supports of 8mm thick.

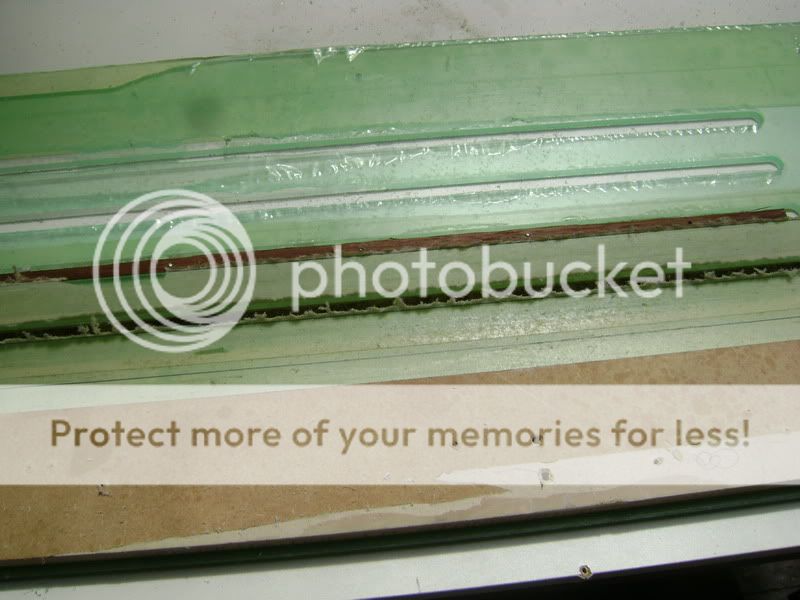

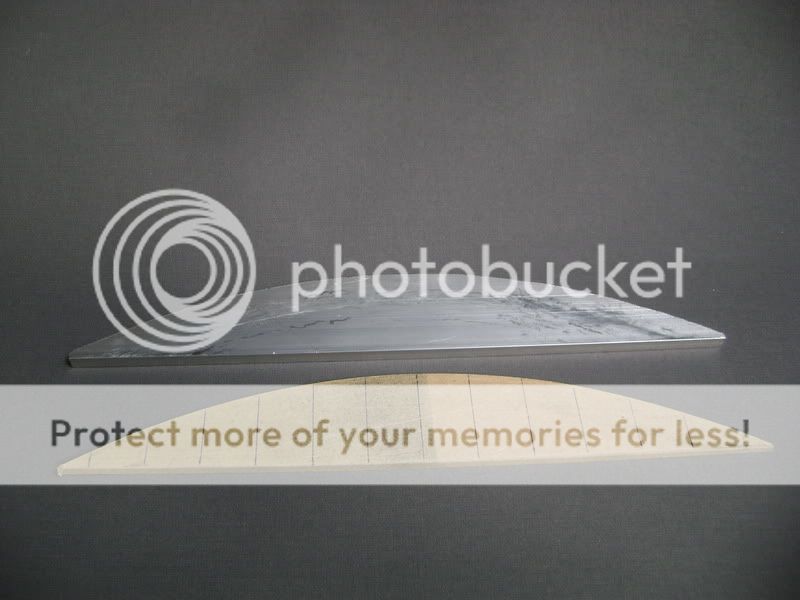

These have the same rounding as the plexi.

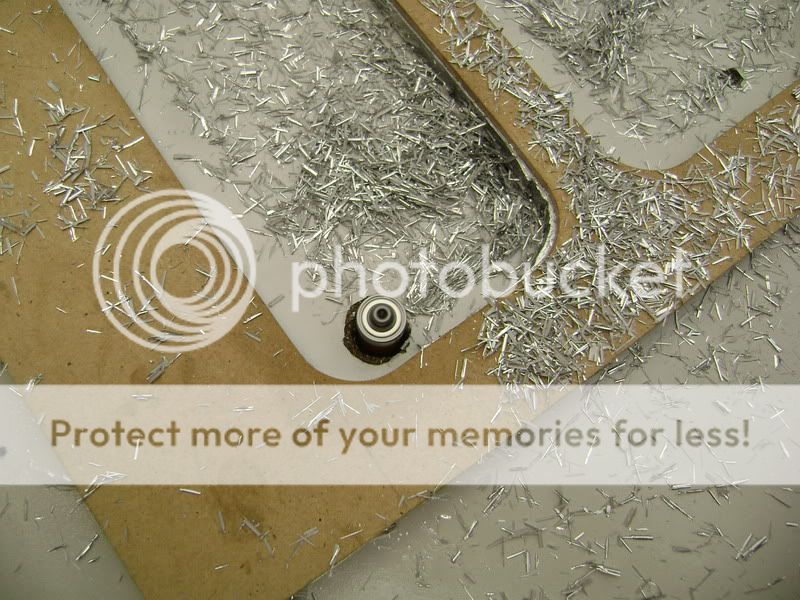

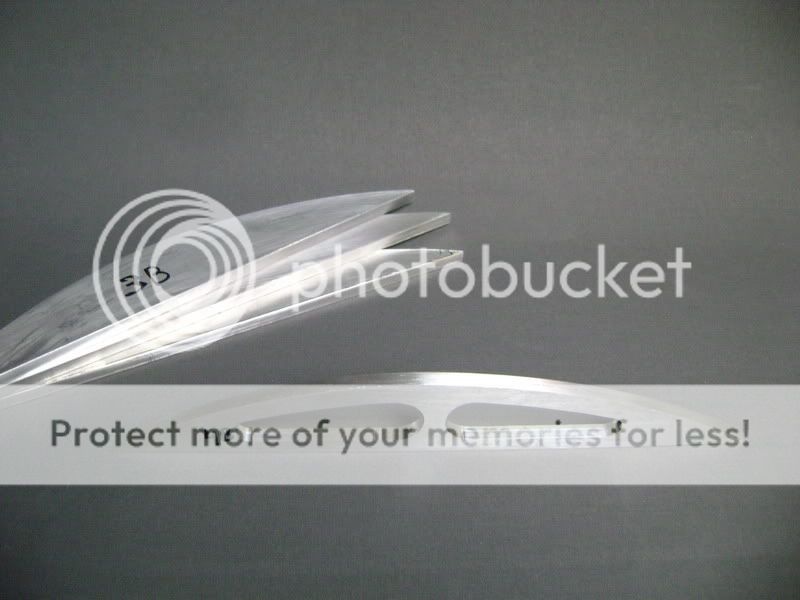

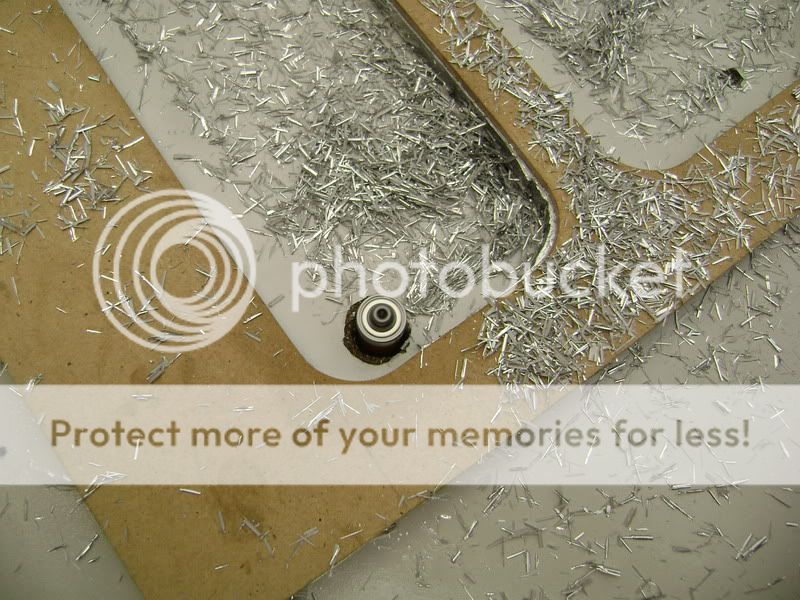

First, I made a mold out of mdf. After that, I drawed out the aluminum piece, and sawed it out.

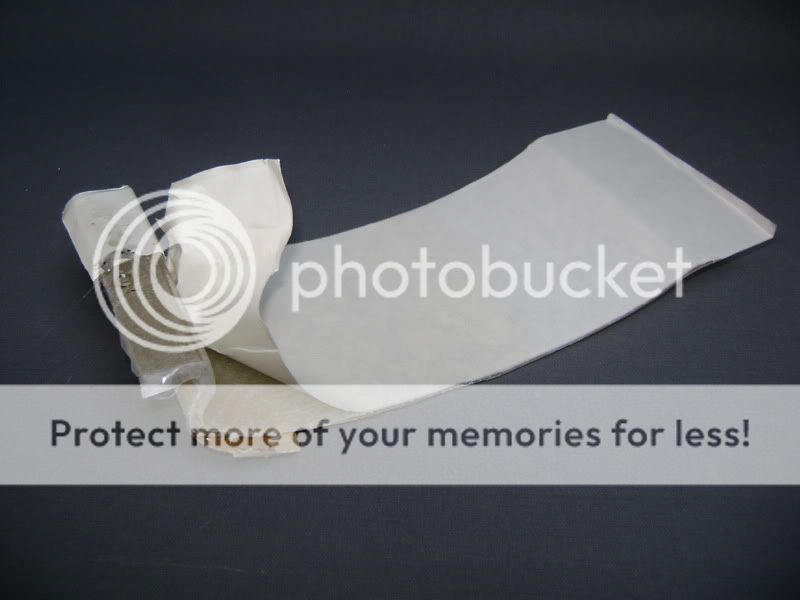

after that, with double sided tape, I sticked it all together.

Once this was done, I held it all to the copy-mill

Here a picture of how it will look.

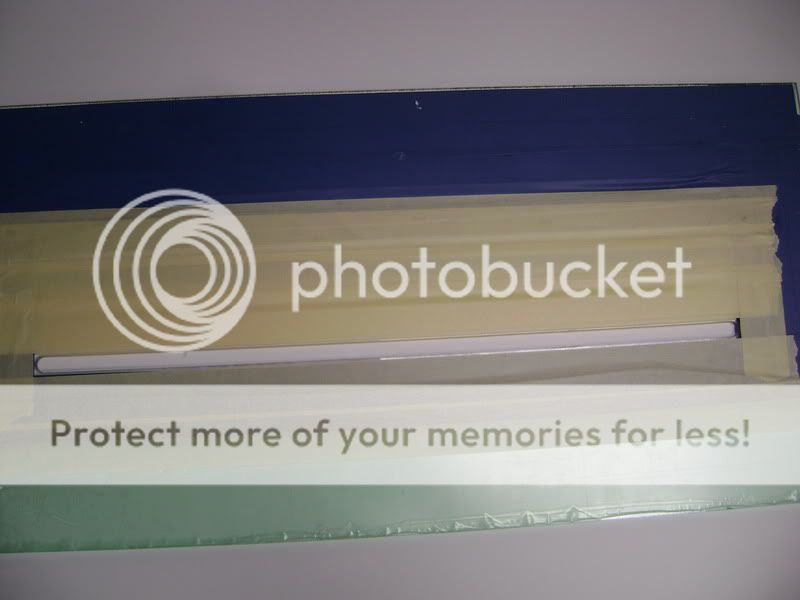

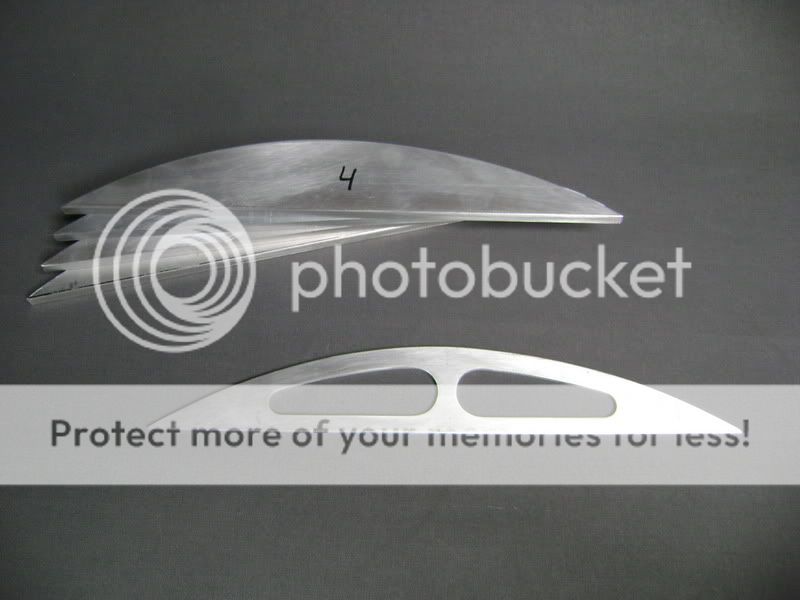

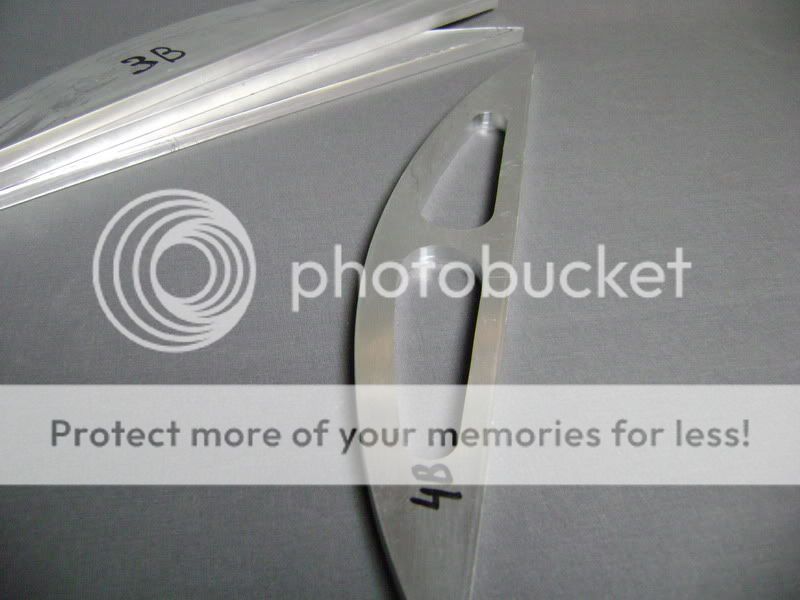

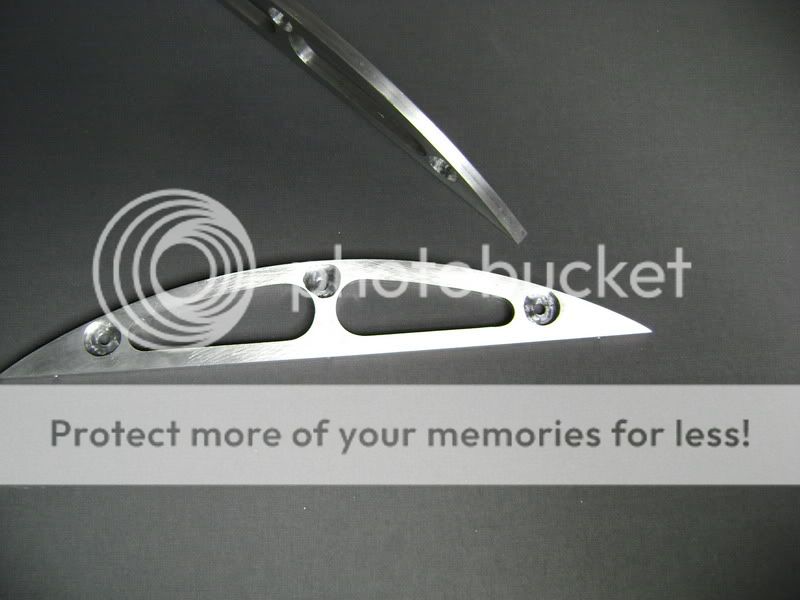

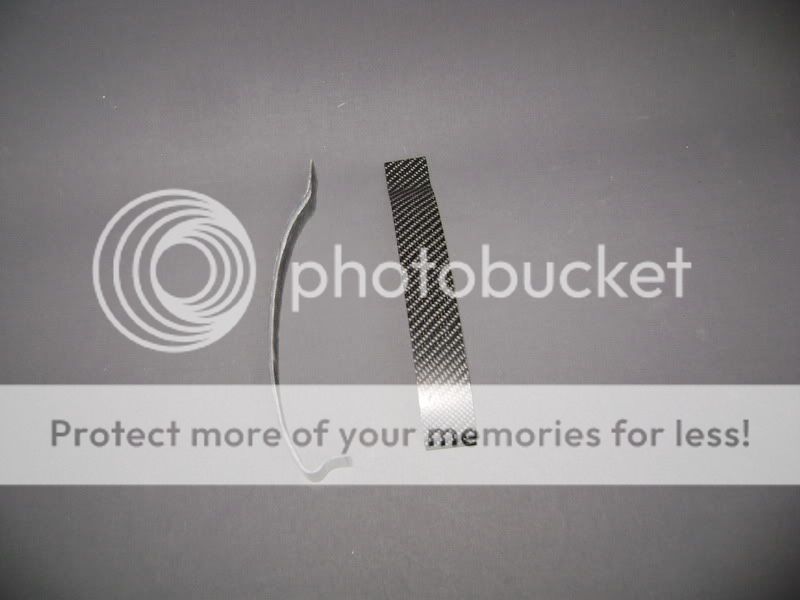

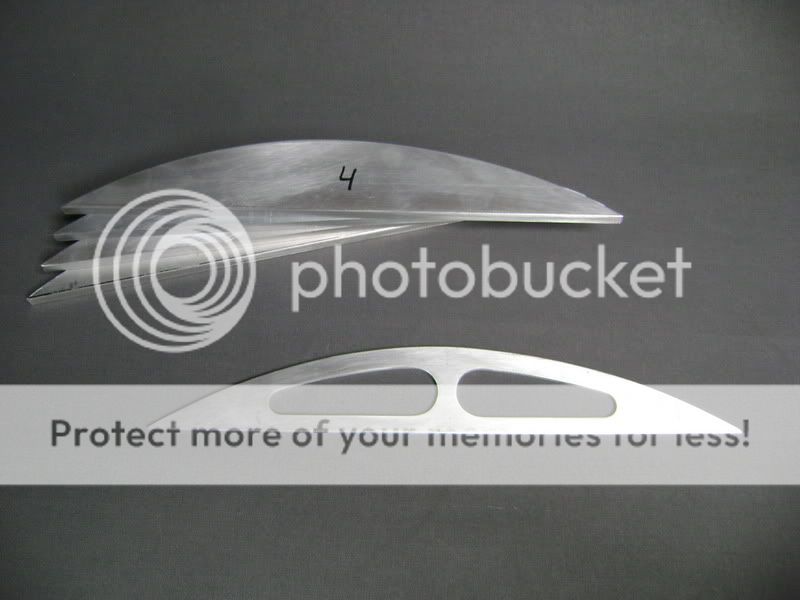

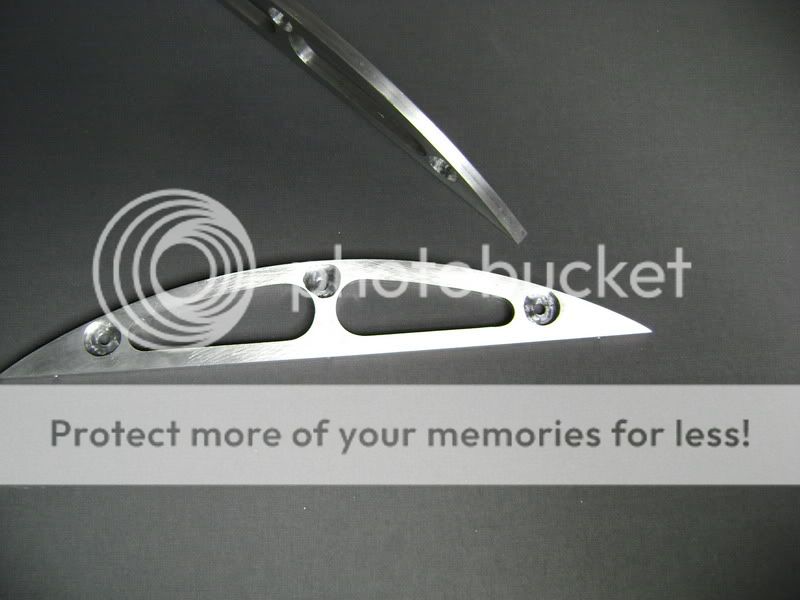

The next step was to “modify” the supports, cause it looks a bit simple like this.

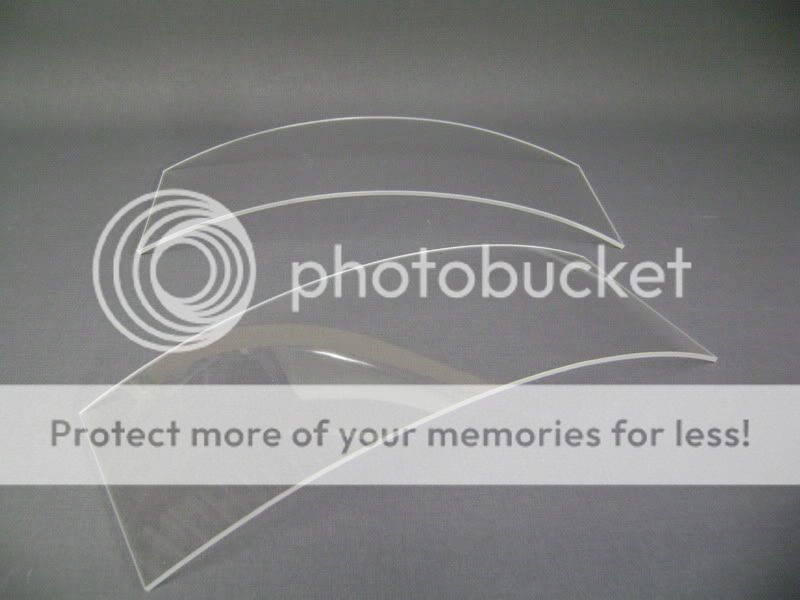

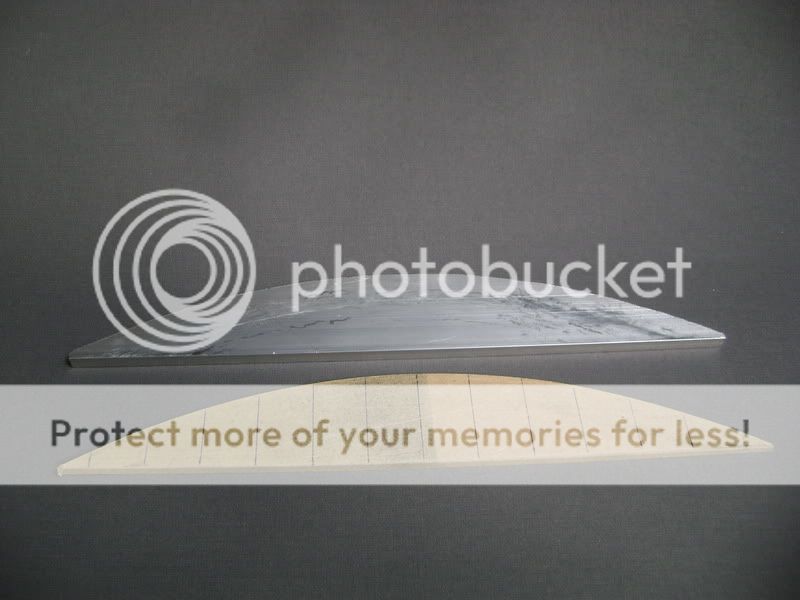

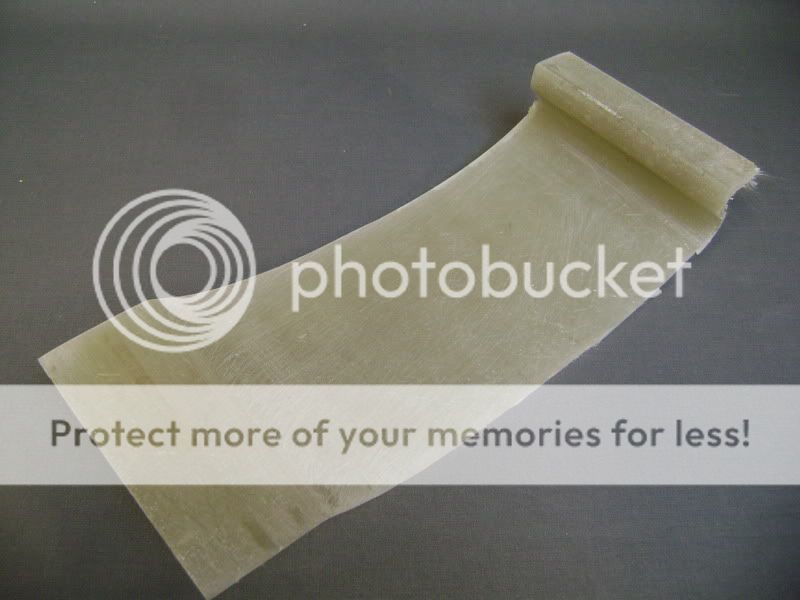

The lower plate is the model I made.

It’s only 4mm thick.

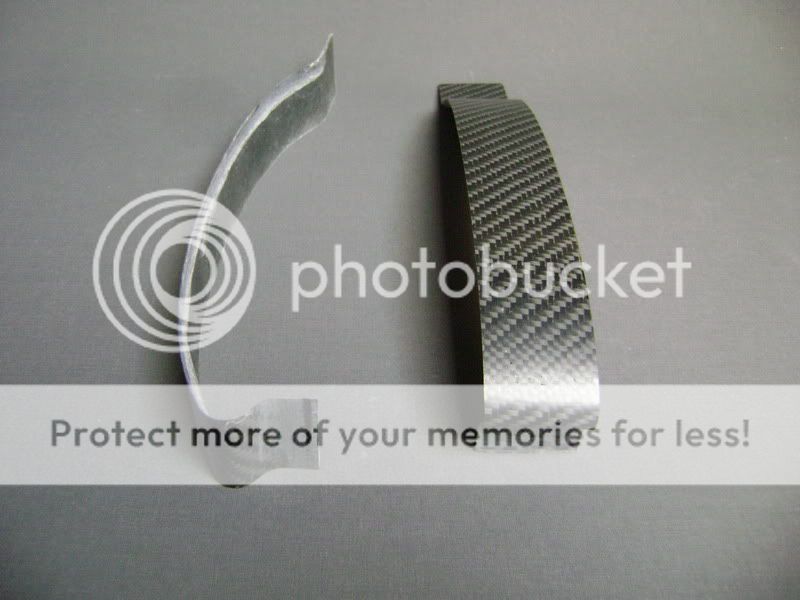

In the piece I needed, I got rid off the aluminum, and sticked it all together again, and then got the mill back in there.

Looks way cooler according to me.

The other 3 will suffer the same cause.

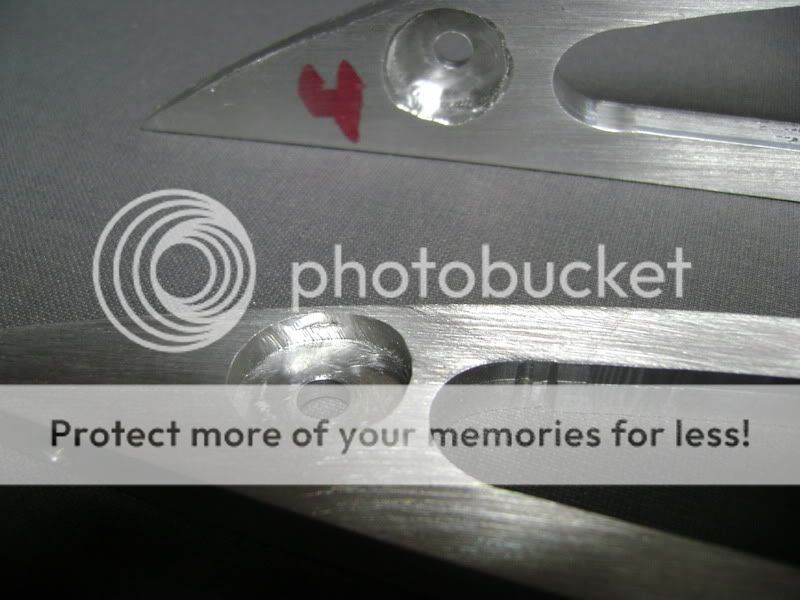

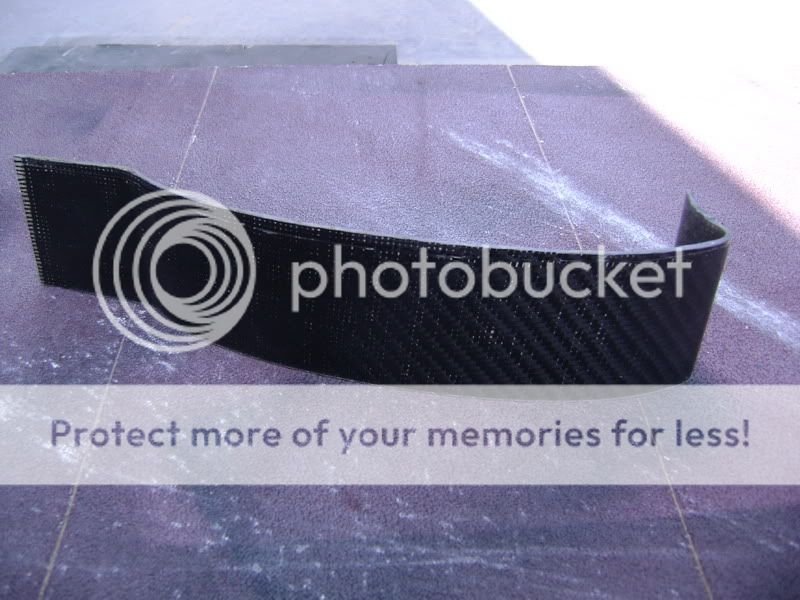

The pattern looks good, but the support still doens’t look the way I wanted too…So I guess I’m going to modify this some more.

Too some issues I didn't get the chance to do much on the ICE.

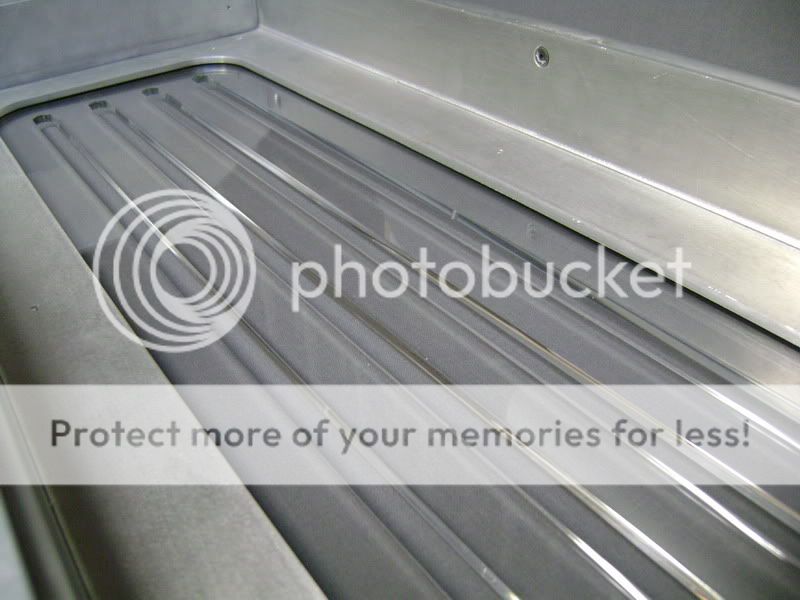

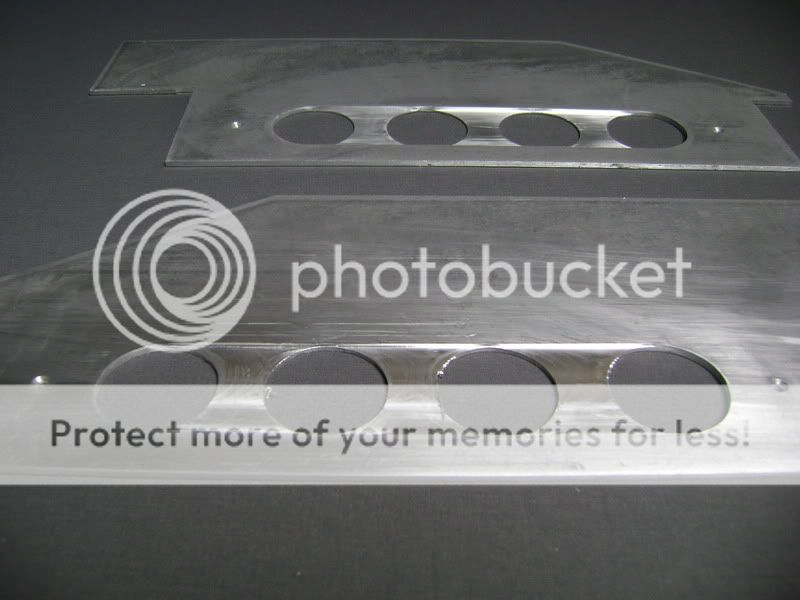

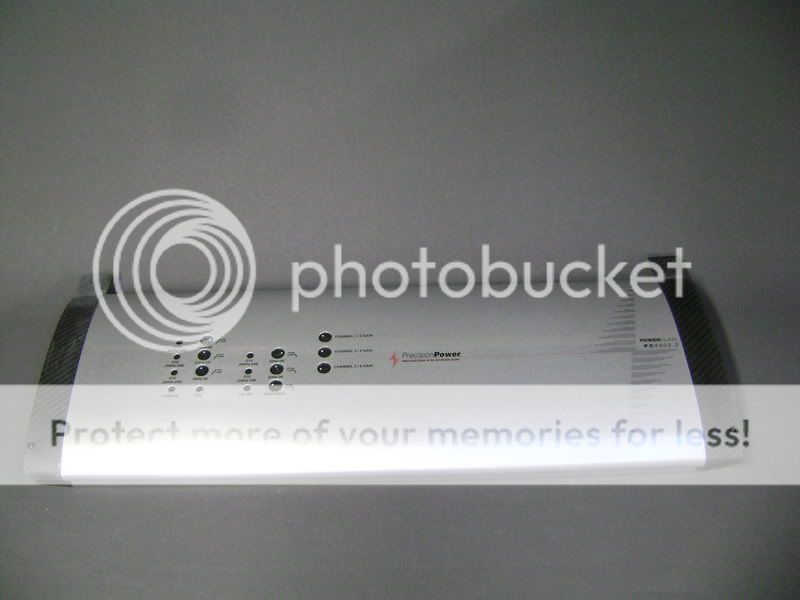

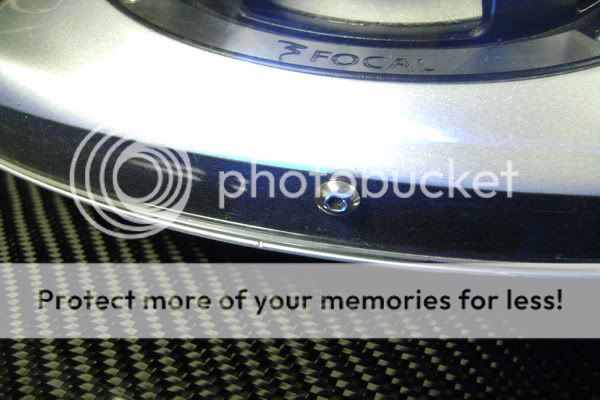

But now , a 'little' update.The 4 toggles where the plexi will lay on to are finished

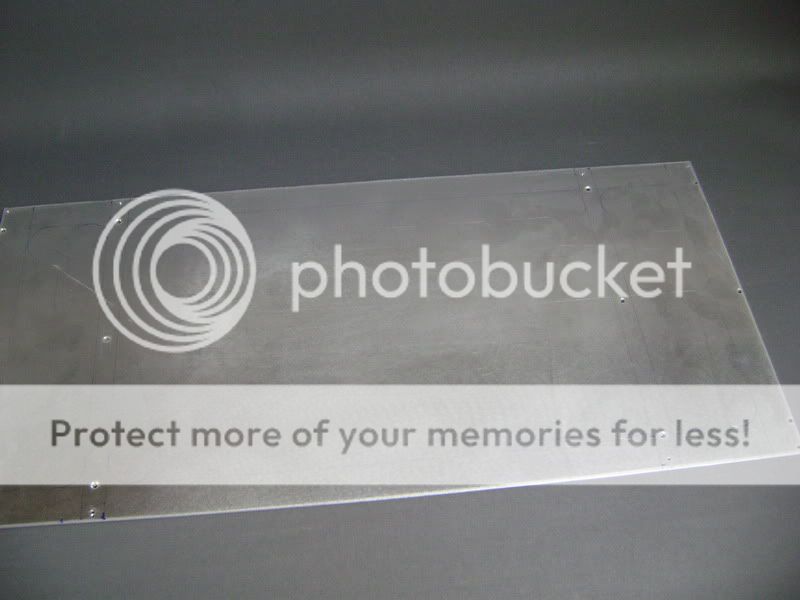

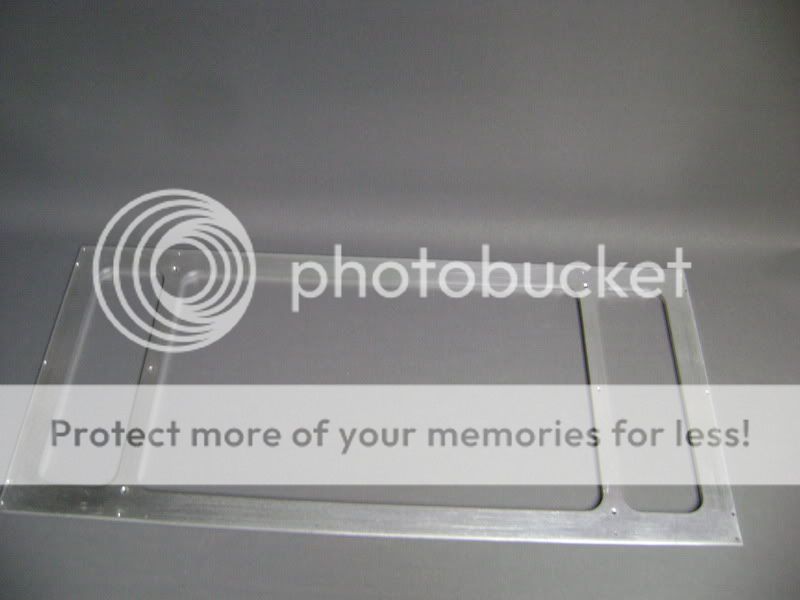

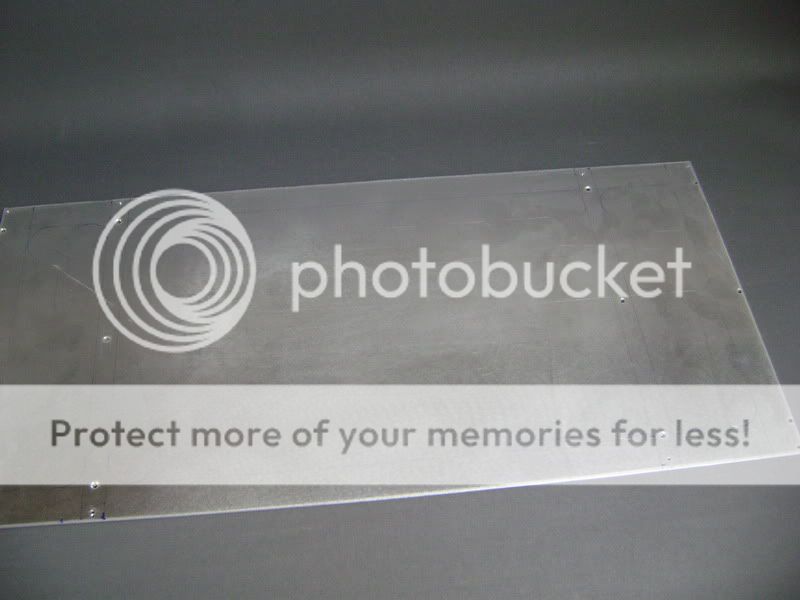

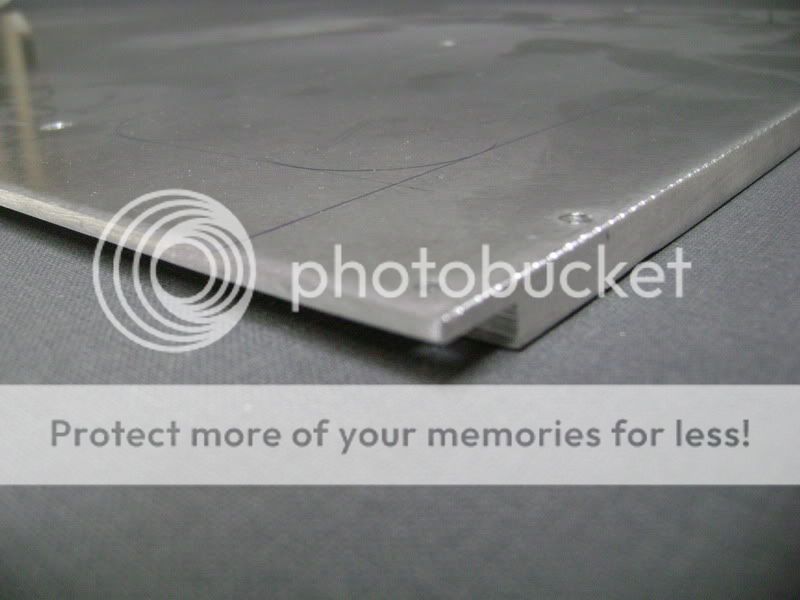

The alu-plate of 8mm where the toggles will get onto.

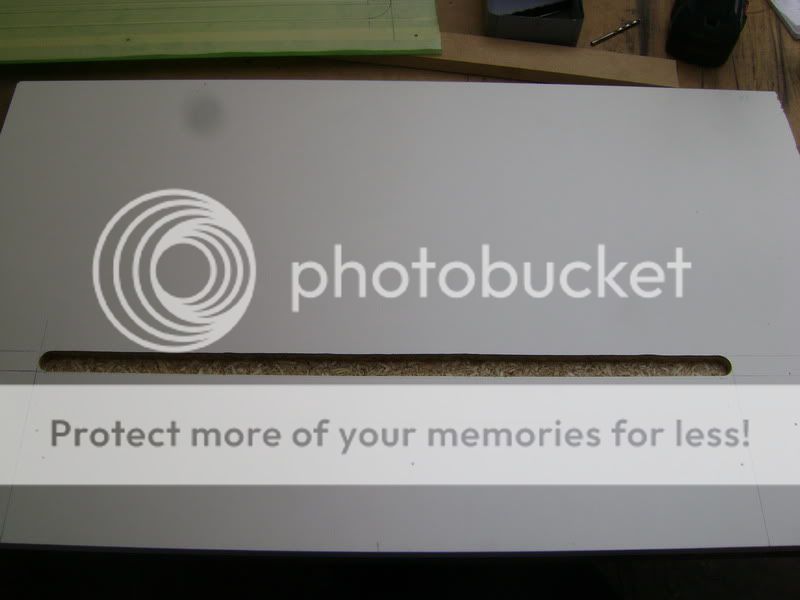

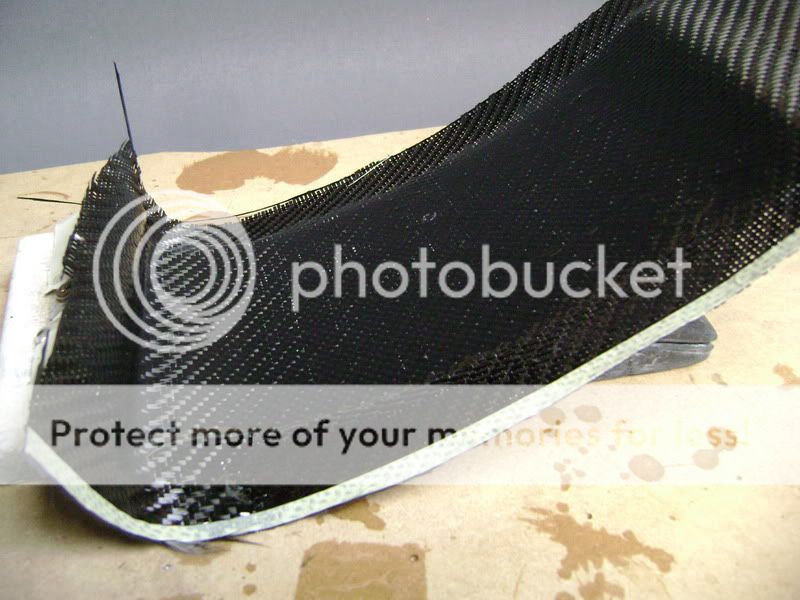

Offcourse, some holes were needed here, otherwise you wouldn't be able to see the amplifier.This is the mold I made of 4mm thick MDF wood.

Layed this on the aluminum and drawed it out

Then, I drilled some holes, and sawed it all out with the electric jigsaw

Pasted the MDF mold on to it.

Then I mounted my upper-mill once again under the table to do some dangerous stuff :)

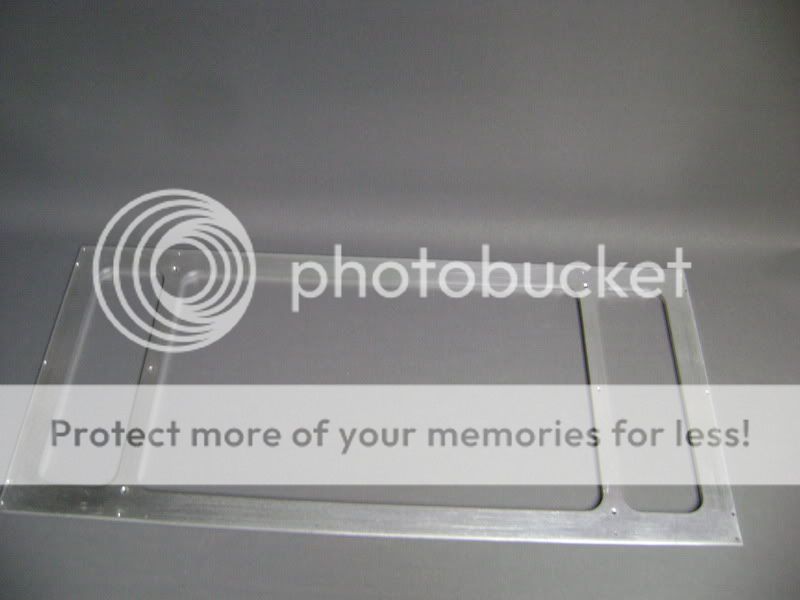

Here the result

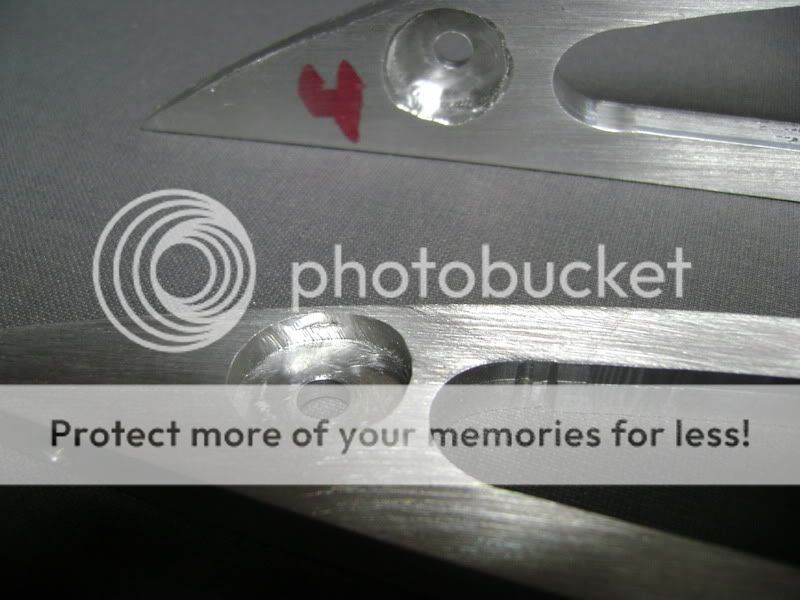

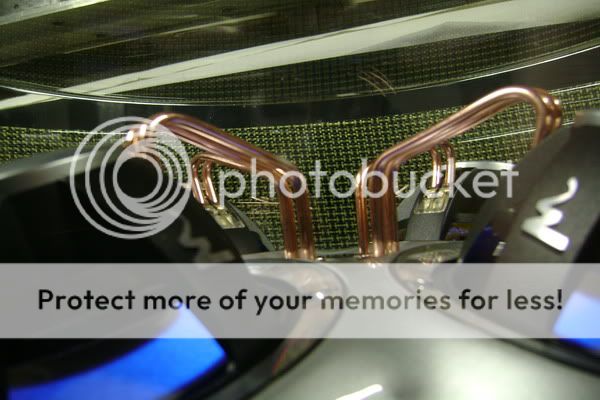

Then I 'modified' the outer toggles.

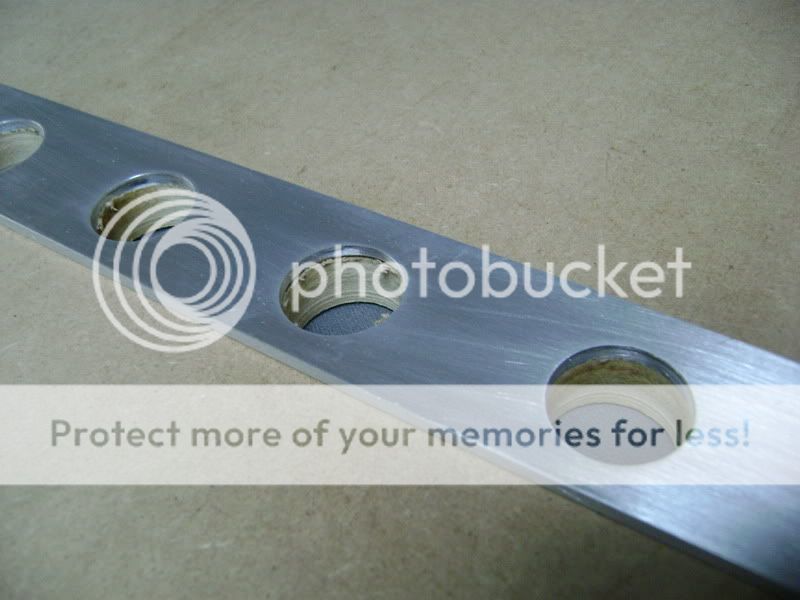

Because a M6 bar with screw-thread will get into this one, I had to drill the hole much bigger, so the nut is sunk into it all.

Made it big enough so it would be possible to get a 10 on there as well

In all toggles I tapped a screw-thread of M5, to fasten them at the bottom

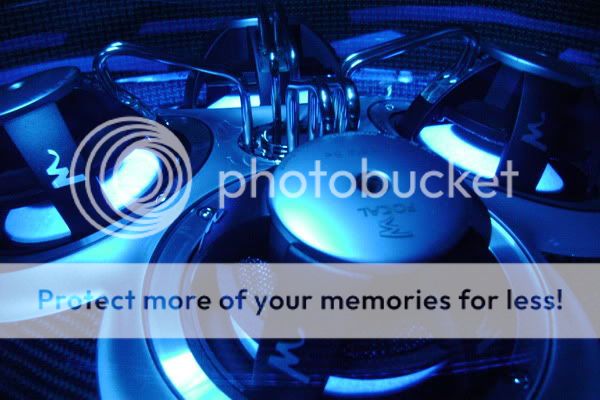

Once I had all of this, I could begin the mounting.

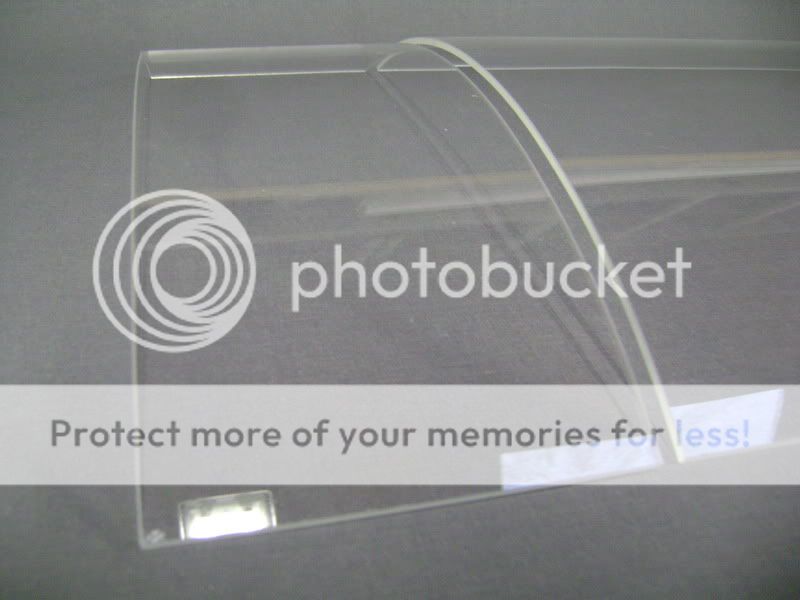

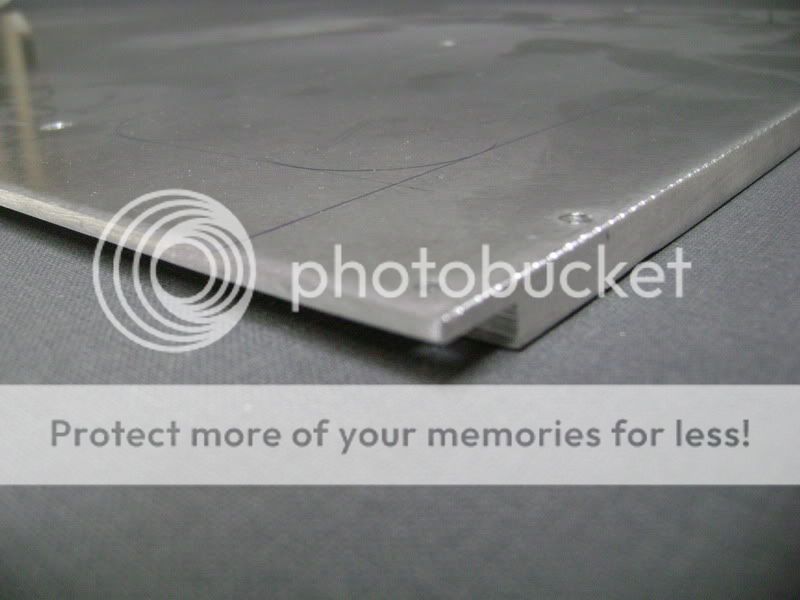

The front and back of the thick plate, I milled in a gap whereto I screwed a big L onto.SO I have a nice finishing touch, and the plexi is tense.

Printable version

Printable version

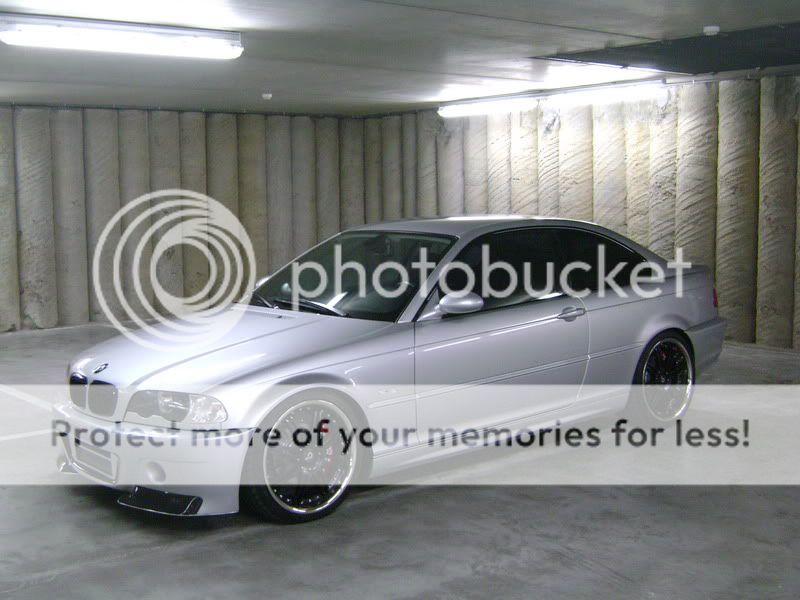

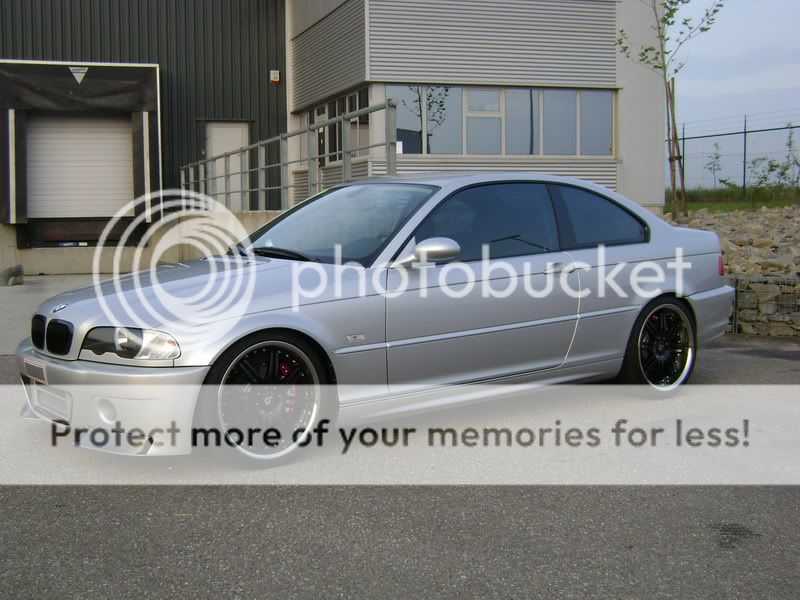

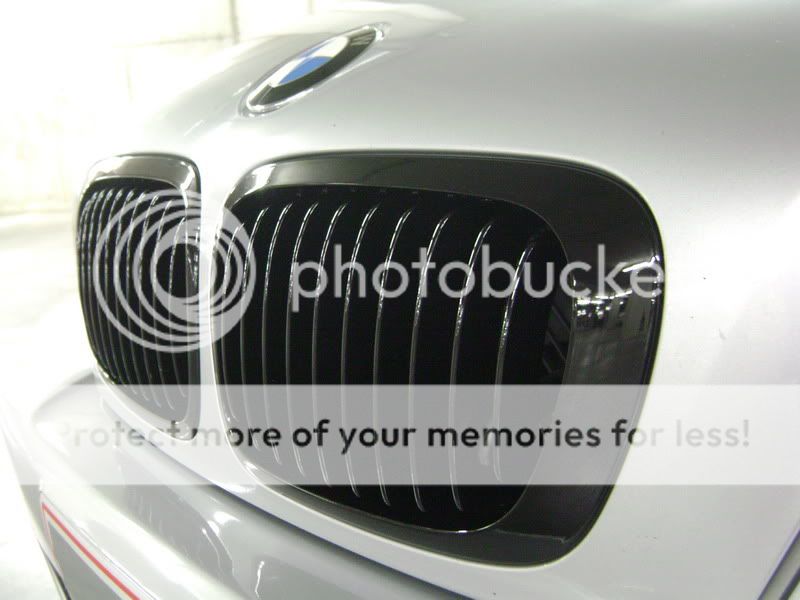

These are some pictures I took in daylight

These are some pictures I took in daylight

The windowmoldings on the side please me also more that I tought.

The windowmoldings on the side please me also more that I tought.