Posted: March 24, 2010 at 12:01 PM / IP Logged

Posted: March 29, 2010 at 12:50 AM / IP Logged

Posted: March 29, 2010 at 10:08 AM / IP Logged

Posted: March 31, 2010 at 1:34 PM / IP Logged

Posted: March 31, 2010 at 1:35 PM / IP Logged

Sorry, you can NOT post a reply.

This topic is closed.

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Thursday, January 29, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Thursday, January 29, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

You could make the entire enclosure out of fiberglass but I do not think it would be practical. In the event that you just really want to take on an entire fiberglass project I would suggest that you begin by cutting the mounting hole from your bed liner then make a plug (mold) of your enclosure using floral foam.

You could make the entire enclosure out of fiberglass but I do not think it would be practical. In the event that you just really want to take on an entire fiberglass project I would suggest that you begin by cutting the mounting hole from your bed liner then make a plug (mold) of your enclosure using floral foam.

Glue blocks together using spray glue and then sand to shape using 36 grit. Use spray glue and aluminum foil to cover your plug then wax it with regular carnauba car wax. Put it on thick and don't rub it off. Glass over that with 4 layers of 1.5 oz. mat and you have your piece.

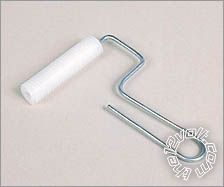

Don't worry about laying glass on a vertical surface. Get yourself a roller also available from tapplastics and role the glass as you apply it.

Glue blocks together using spray glue and then sand to shape using 36 grit. Use spray glue and aluminum foil to cover your plug then wax it with regular carnauba car wax. Put it on thick and don't rub it off. Glass over that with 4 layers of 1.5 oz. mat and you have your piece.

Don't worry about laying glass on a vertical surface. Get yourself a roller also available from tapplastics and role the glass as you apply it.  you will find that as long as the glass is not over or under saturated with resin that it will sick just fine. In fact I just glassed a sub enclosure last week that required me to apply in this manner totally upside down. I had no problems with the glass sticking. Pay attention to the temperature and the amount of MEKP that you use. I use 1cc MEKP to 1 oz. of resin 60-70 degrees and 1/2 cc. 70-75 and 1/4 cc to 1 oz for 75 degrees and up. If you use to little gravity will have a chance to pull your glass down (not on a vertical surface that has been properly rolled out but definitely on an inverted surface).

I manage a shop with a bunch of guys that along with myself do this type of stuff all day long. So when I say that this project is not practical to do entirely from fiberglass I know what I speak. Having said that I applaud anyone that truly attempts to further their own experience despite the easy road. The best of luck to you and let me know if you have any question that I might be able to answer for you.

you will find that as long as the glass is not over or under saturated with resin that it will sick just fine. In fact I just glassed a sub enclosure last week that required me to apply in this manner totally upside down. I had no problems with the glass sticking. Pay attention to the temperature and the amount of MEKP that you use. I use 1cc MEKP to 1 oz. of resin 60-70 degrees and 1/2 cc. 70-75 and 1/4 cc to 1 oz for 75 degrees and up. If you use to little gravity will have a chance to pull your glass down (not on a vertical surface that has been properly rolled out but definitely on an inverted surface).

I manage a shop with a bunch of guys that along with myself do this type of stuff all day long. So when I say that this project is not practical to do entirely from fiberglass I know what I speak. Having said that I applaud anyone that truly attempts to further their own experience despite the easy road. The best of luck to you and let me know if you have any question that I might be able to answer for you.