Posted: January 12, 2011 at 12:56 AM / IP Logged

Posted: January 13, 2011 at 3:48 AM / IP Logged

Posted: January 17, 2011 at 2:21 AM / IP Logged

Posted: January 17, 2011 at 11:31 AM / IP Logged

Posted: January 17, 2011 at 4:52 PM / IP Logged

Posted: January 17, 2011 at 10:47 PM / IP Logged

Posted: January 18, 2011 at 2:10 AM / IP Logged

Posted: January 18, 2011 at 10:16 AM / IP Logged

Posted: January 18, 2011 at 3:56 PM / IP Logged

Posted: January 19, 2011 at 1:46 AM / IP Logged

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Wednesday, March 4, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Wednesday, March 4, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

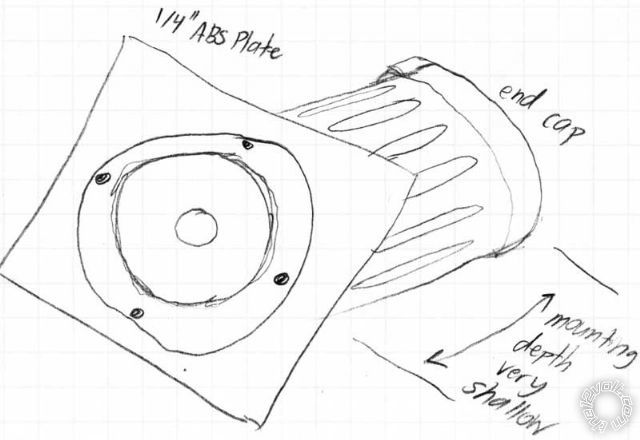

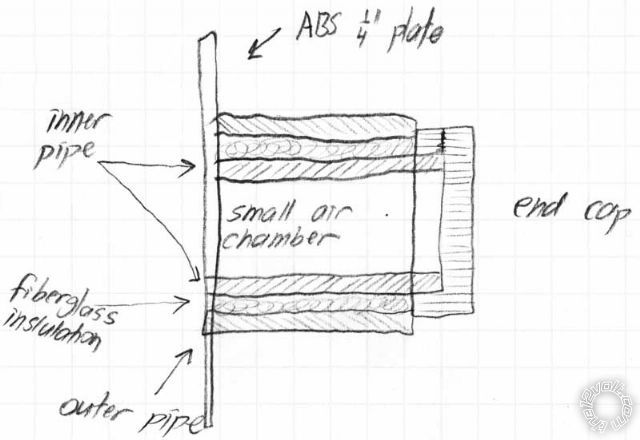

Now take another pipe slightly larger than the first pipe, and slide them together. Choose a size so that there is a decent gap between the tubes. Grab some fiberglass insulation and fill this gap. Now you have a medium inner tube with an endcap, a bunch of insulation wrapped around it, and a larger outer tube sandwiching it all together.

Now take another pipe slightly larger than the first pipe, and slide them together. Choose a size so that there is a decent gap between the tubes. Grab some fiberglass insulation and fill this gap. Now you have a medium inner tube with an endcap, a bunch of insulation wrapped around it, and a larger outer tube sandwiching it all together.

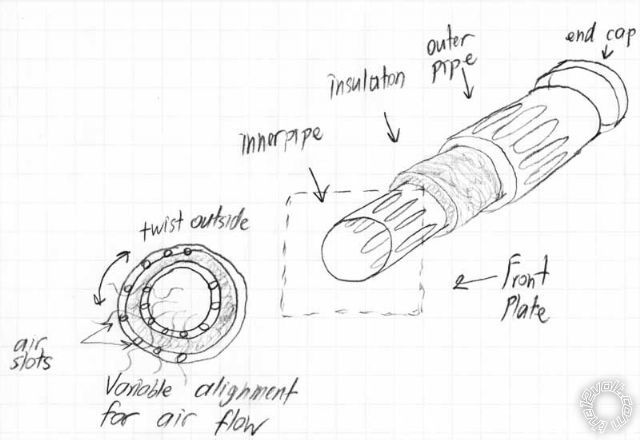

Now disassemble everything. Using whatever tools you can, create lots of slots longwise in both tubes. I'm aiming for a width of 1/4" to 3/8" and as long as possible. Most resources I have found recommend the surface area of the vent should be about 1/2 the surface area of your woofer. So for my 6" woofer (28 sq in.), I should have about 14 sq inches worth of vents.

Now disassemble everything. Using whatever tools you can, create lots of slots longwise in both tubes. I'm aiming for a width of 1/4" to 3/8" and as long as possible. Most resources I have found recommend the surface area of the vent should be about 1/2 the surface area of your woofer. So for my 6" woofer (28 sq in.), I should have about 14 sq inches worth of vents.

Notice how if you only drill slots on half or three quarters of the circumference of each tube, you can twist them to vary the amount of air allowed to "leak". Should be a super easy way to tune the aperiodic vent. For more coarse adjustments, of course we can change the amount of fiberglass we stuff in there.

One thing not noted on the drawings is to be sure the ends of the pipes are sealed. The ONLY path from the rear of the woofer to the outside of the enclosure needs to be through the inner slots, through the fiberglass, and then finally through the outer slots. I plan to find some rubber gaskets for this in the plumbing department at the hardware store.

--

Comments and critique welcome!

-J

Notice how if you only drill slots on half or three quarters of the circumference of each tube, you can twist them to vary the amount of air allowed to "leak". Should be a super easy way to tune the aperiodic vent. For more coarse adjustments, of course we can change the amount of fiberglass we stuff in there.

One thing not noted on the drawings is to be sure the ends of the pipes are sealed. The ONLY path from the rear of the woofer to the outside of the enclosure needs to be through the inner slots, through the fiberglass, and then finally through the outer slots. I plan to find some rubber gaskets for this in the plumbing department at the hardware store.

--

Comments and critique welcome!

-J

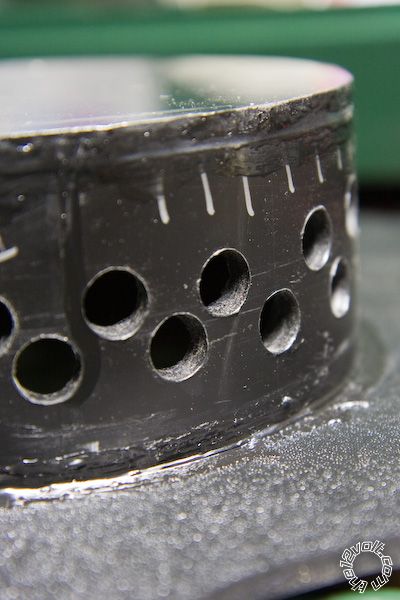

To glue the ABS together, I'm using a sweet technique I found elsewhere. Keep all the fine dust-like shavings created when cutting/sawing/sanding the abs pipe into shape. Then, mix it with a little bit of acetone to create a thick sludge. I find the bottom of a coke can works great for this. Apply the sludge (generously) to both faces you want to "weld" together, and clamp overnight. Working time once you mix the shavings and acetone is at least a few minutes, or until the acetone evaporates. I'm surprised how well this worked, it's like welding with a q-tip !

To glue the ABS together, I'm using a sweet technique I found elsewhere. Keep all the fine dust-like shavings created when cutting/sawing/sanding the abs pipe into shape. Then, mix it with a little bit of acetone to create a thick sludge. I find the bottom of a coke can works great for this. Apply the sludge (generously) to both faces you want to "weld" together, and clamp overnight. Working time once you mix the shavings and acetone is at least a few minutes, or until the acetone evaporates. I'm surprised how well this worked, it's like welding with a q-tip !

I'll post some more over the next few days.

I'll post some more over the next few days.

-J

-J

The padding is held in place by a strip of sheet metal along the top edge because the woofer basket needs the clearance. The bottom is held in place by a C-shape section of the 6" pipe that has been trimmed down to size.

The padding is held in place by a strip of sheet metal along the top edge because the woofer basket needs the clearance. The bottom is held in place by a C-shape section of the 6" pipe that has been trimmed down to size.

Installed in the door, makes for a very tight fit. Cannot comment on performance yet, need to get some sleep first. And yes, that is Grace Water Shield roofing material on the door, don't laugh (okay maybe a little). It's 1/10'th the cost of dynamat or other "professional" products, the adhesive is a thousand times better, it weighs the same, and does not smell like asphalt. I'm using it to seal the door as air-tight as possible, not prevent sound from coming through the door.

For that, I have a sheet of Acoustiblok ready to lay over the top. If you're not familiar with it,

Installed in the door, makes for a very tight fit. Cannot comment on performance yet, need to get some sleep first. And yes, that is Grace Water Shield roofing material on the door, don't laugh (okay maybe a little). It's 1/10'th the cost of dynamat or other "professional" products, the adhesive is a thousand times better, it weighs the same, and does not smell like asphalt. I'm using it to seal the door as air-tight as possible, not prevent sound from coming through the door.

For that, I have a sheet of Acoustiblok ready to lay over the top. If you're not familiar with it,  -J

-J