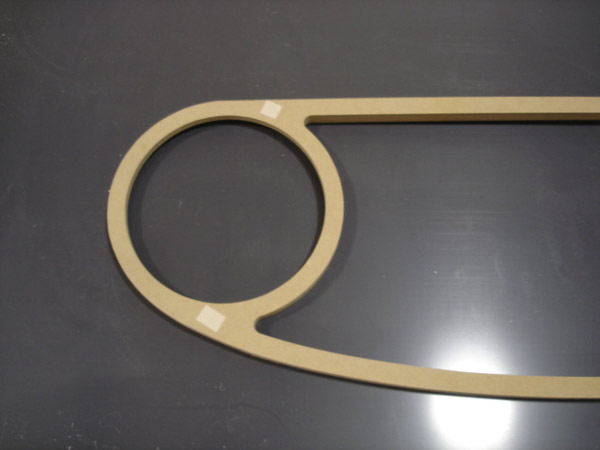

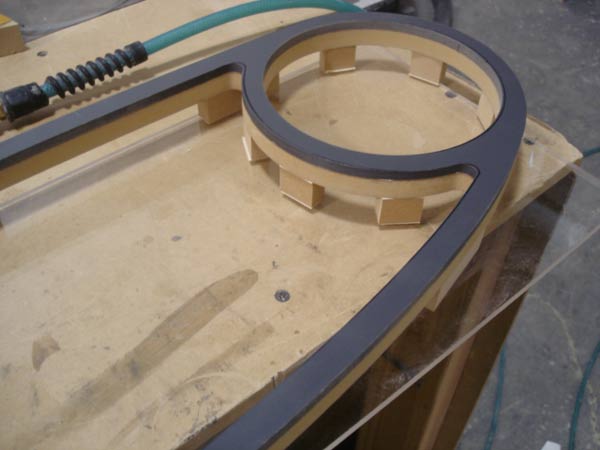

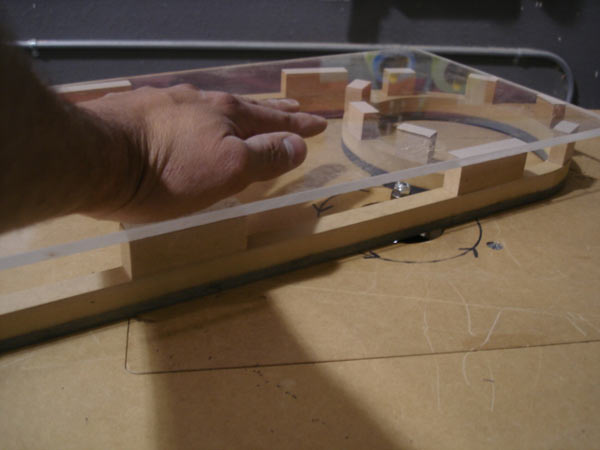

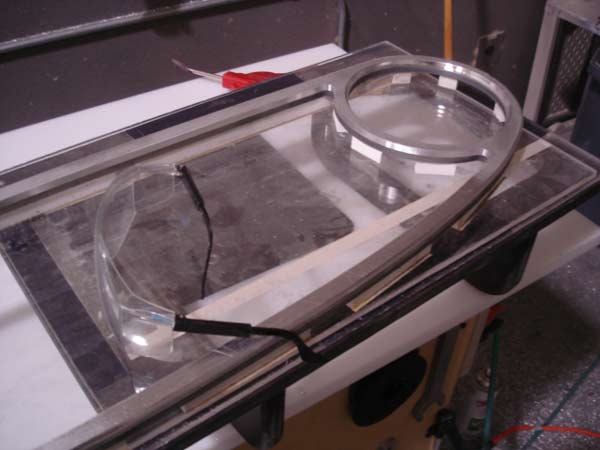

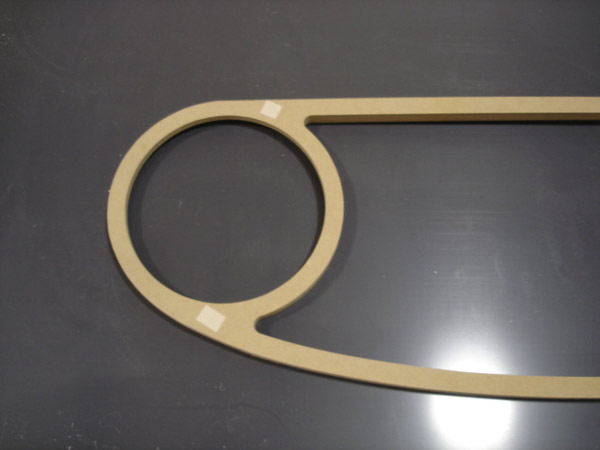

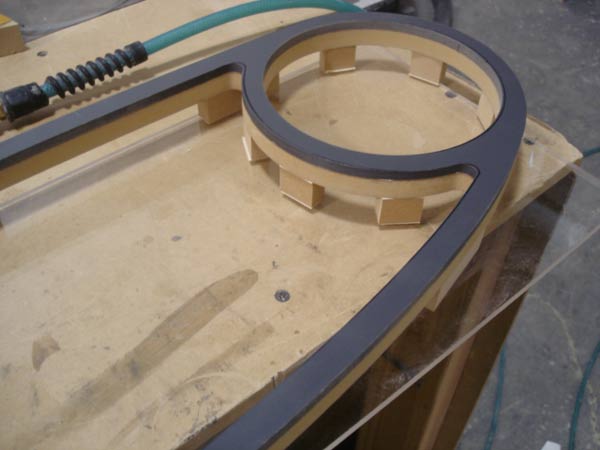

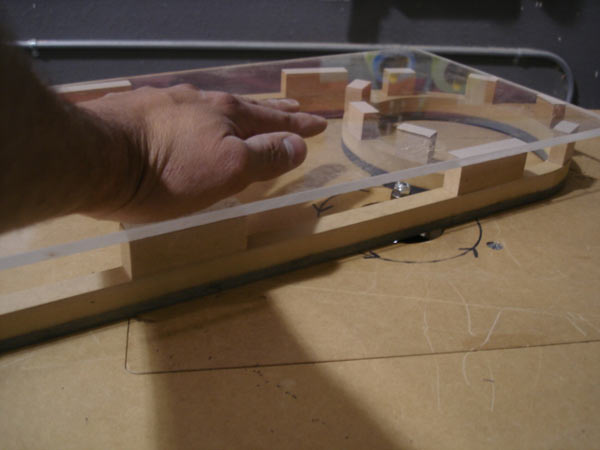

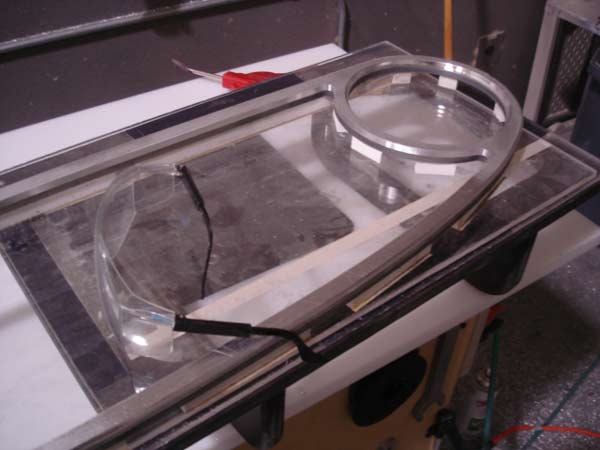

Cut/rout the parts that you want make out of aluminum out of ¾ MDF. Make them perfect. Then rout a duplicate part out of ¼” PVC. You can get it here www.tapplastics.com. Then rough cut your part from 1/8” – ¼ “ aluminum. Use your PVC part as a guide. I use double stick tape to laminate the PVC part to the aluminum sheet. Then I rest the base plate of my jig saw directly on the PVC part. This way the aluminum chips do not get wedged between the jig saw base and the aluminum base and dig into the surface of the aluminum sheet. Then adhere the MDF- PVC-aluminum stack to a sheet of plexi or a router shield. Apply cutting oil to the surface of the aluminum that the router will be cutting. Only apply oil and rout a 12” section or so at a time. Any more than that and you risk the oil eating a way at the double sided tape and the aluminum breaking away while you are routing. Take care not to get oil on the tape edge. Don’t use spray type oils!

Standard router bits cut through aluminum effortlessly as long as you take it easy. I use run of the mill $15 dollar two flute bits. I do a lot of cutting and these last for a couple of moths.

Larger diameter bits cit smoother and stay cooler. I use a ¾” diameter ½” shank flush cut for most of my work.

I specify PVC for many reasons. Get PVC for best results. If you decide not to and you have luck with another material please let me know.

Use non foam double side tape. Foam tape has to much give. Don’t use the clear stuff designed for emblems. It has a very low working temp. I use the stuff that looks and feels like double sided masking tape. You can find it here: www.tapplastics.com.

If the part that I am working on is intricate and lacks surface area I use heat activated contact cement in lieu of the tape (brushed on, heat the aluminum). You can find it here: www.selectproducts.com

Get creative with routering decorative edges on your pieces. This can make your piece really outstanding.

Just like wood don’t burn the bit. If your piece is hot to touch you are going to fast.

You can also laminate plexi (black or clear looks cool) to a thinner aluminum and rout them as one piece for a cool look.

Don’t use a standard metal jig saw blade. I use a Bosh aluminum/fiberglass bi-metal blade. You can find them any where Bosh blades are sold.

Things to know when buying aluminum:

Soft aluminum is more difficult to cut but easier to polish.

Harder grades of aluminum are easier to cut (dose not build up on blade as easily) but is harder to polish.

When purchasing sheets of aluminum the price goes up for pieces thinner than 1/8” do to manufacturing difficulties and thicker than ¼” do to mass. 1/8” is the easiest to get and easiest to work with.

In spite of the long explanation I have provided here this is all quite simple and easy to do given a little experimentation doing so. I have tried to include enough info to keep you out of any pitfalls. PM me with any questions. Good luck.

Printable version

Printable version

Mine doesn't have the gauges just a blank. I want to extend both ends of the console. I want to make it longer to go between the seat for the cup holders and forward and up to meet the dash for the ipod and head unit.

From reading the forum I get the idea of glass and how to but just scratching my head to make the frame for this.

I am thinking of using wood side panels that are attached to the console to make the long part for the cup holders. Then using foam for the funky head unit part. I don't know any thoughts on this would be greatly appreciated. Here is a pic of what I am sort of trying to achieve.

Mine doesn't have the gauges just a blank. I want to extend both ends of the console. I want to make it longer to go between the seat for the cup holders and forward and up to meet the dash for the ipod and head unit.

From reading the forum I get the idea of glass and how to but just scratching my head to make the frame for this.

I am thinking of using wood side panels that are attached to the console to make the long part for the cup holders. Then using foam for the funky head unit part. I don't know any thoughts on this would be greatly appreciated. Here is a pic of what I am sort of trying to achieve.

Brad

Brad