Posted: December 29, 2007 at 4:02 PM / IP Logged

Posted: December 29, 2007 at 7:05 PM / IP Logged

Sorry, you can NOT post a reply.

This topic is closed.

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Saturday, February 7, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Saturday, February 7, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

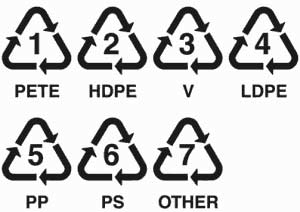

PP, PPE, PPO are not compatible with polyester fiberglass resins or fillers. ABS, PC,PVC are.

There are several expensive epoxy based products intended for automotive bumper repair that will not work for you either due to the limited surface area that you have to work with. I do not suggest going down that road.

I suggest purchasing the basic two part 30 minute syringe type epoxy that you can find at any hardware store. Grind the back of your door panel. You want a very rough surface to bond to. Cut 3 pieces of 3”x3” fiberglass woven cloth (Not matt it is not compatible). Wet the repair surface with epoxy. Lay down one layer of cloth. Wet again, and so on. Use two bondo cards to work the epoxy into the cloth (one to hold cloth one to squeegee).

And you do not have to worry about any material running down the panel because the panel will be horizontal on a work table and in a warm room for 24 hours while the epoxy fully cures.

PP, PPE, PPO are not compatible with polyester fiberglass resins or fillers. ABS, PC,PVC are.

There are several expensive epoxy based products intended for automotive bumper repair that will not work for you either due to the limited surface area that you have to work with. I do not suggest going down that road.

I suggest purchasing the basic two part 30 minute syringe type epoxy that you can find at any hardware store. Grind the back of your door panel. You want a very rough surface to bond to. Cut 3 pieces of 3”x3” fiberglass woven cloth (Not matt it is not compatible). Wet the repair surface with epoxy. Lay down one layer of cloth. Wet again, and so on. Use two bondo cards to work the epoxy into the cloth (one to hold cloth one to squeegee).

And you do not have to worry about any material running down the panel because the panel will be horizontal on a work table and in a warm room for 24 hours while the epoxy fully cures.