The anti-cap argument is more about cost, waste, and effectiveness.

Cheaper batteries will give at least the same transient response but usually have 100's or 1,000's of time the reserve power of a cap.

My recommendation has been to fit a small AGM (VRLA) battery in place of the cap.

The 12V-7AH battery is of similar volume to a cap and, being a VERY common battery, is very cheap (typically the "best bang for bucks" for small batteries). It also has the potential (no pun) to jump start your car (7AH where common in emergency starter packs, though these days they tend to use ~15AH).

I was most impressed recently when I found Yuasa (good brand) NP7-12 (12V 7AH)AGM batteries for AUD$35. That's cheaper than equivalent sealed and gel batteries (typically $50). [Note however this NP battery was intended for standby use - but it still has low ESR and delivered cranking current despite its "45A" rating! But maybe cyclic versions are also cheap.]

But even larger AGMs are often cheaper than stiffening caps.

And I have yet to see a vehicle crank off a capacitor!

The arguments about extra loads or strain after discharge are not that relevant.

The cap will not drop below battery or alternator voltage (excluding line losses).

The alternator is self limiting. (In any case, it has a short-circuit current capability double its transient short circuit current. That's its sub-transient reactance - not its steady-state reactance/impedance!)

If power to recharge was an argument, then the capacitor would always win an efficiency argument because it is nearly 100% efficient. Battery efficiencies are far less.

FYI - The above recharge arguments are often used to argue against other things - like electric fuel pumps, electric fans, etc. Their arguments are usually flawed. (Probably always, but their may be some validity.)

As to caps - when have you seen a discussion of their performance for a sustained bass note?

Wot - no bass note is ever held for more than a second, or fraction of a second?

Wot - the cap fully recharges in between bass notes (despite a LOWER battery and alternator voltage)?

That ends a lot of discussions. I wonder why?

And the above is merely a steady-state situation.

Try getting into transient state discussions!

Even on this site I haven't seen much. My question as to the effect of having a low ESR AGM and lower ESR cap feed a much HIGHER ESR amp (a steady-state even "DC" question) is still unanswered. (And do PWM/SMPS really need input voltage smoothing?)

But as one wise person recently said:

If you want the cap because its chrome, lights up, and looks cool, it'll do good. lol

Otherwise use a cheaper battery. (But note the issues with paralleling batteries.)

(Won't a battery look cooler than a cap? A battery means SERIOUS power. And then a voltmeter of your choice - though that should be in the cabin. So a battery temp meter instead! Yeah..!)

Amen!

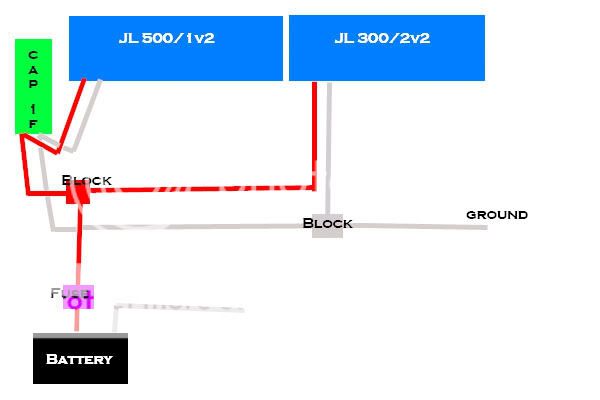

PS - nice seeing others in agreement with "only one fuse" at the battery end. (Assuming end equipment has its own protective fusing - as they should! - and the fuse suits the smallest downstream cable.)

I so often met posts that insist that fuses must "match" their cable and the more downstream fuses for smaller cables.

I prefer cables that swap load currents with a fuse that handles the load. (Thereby also protecting the cable because the fuse is smaller that the "cable" fuse required.)

Only smaller downstream cables (taps) need be additionally fused.

Alas those that follow a rule only. (Can I use a 100A fuse instead of the cable's 250A fuse? YES!)

Printable version

Printable version