I have seen many posts asking how many layers of glass to use when building and enclosure.

When I see fiberglass projects from other people I always see the same mistakes.

1. Not enough layers

2. Too much resin

3. Lack of core material

4. The use of the wrong type of resin

Sub boxes need to be as strong as possible. You can not do too many layers! The stronger your enclosure is the more efficient your sub will be. The tricks of the trade involve using 1.5 oz. Random Stranded mat or higher, using a roller, balteck mat as a core, and using vinyl-ester instead of polyester resin.

When done right you can lay 7 layers or so in one shot and get a lightweight nearly bullet proof shell.

Use 1.5 oz random weave stranded mat or heavier. Mat is held together by starch. When weted out with resin the starch breaks down and the mat turns into chop (nothing holding it together). This allows you to make the mat conform to any shape with out those pesky little stands poking out. The key to breaking down the starch is giving the resin solvents a little time (3 minutes or so) and the physical motion of rolling out the resin soaked mat with a roller. I cant stress the roller part enough! The roller will force the resin down into the mat and once the starch breaks down It will force the mat to compact and excess resin will rise to the top. At this point you can lay down more mat to soak up that extra resin. It now becomes apparent just how far resin can really stretch. Much farther than you thought! F the brush! Just use it to get the resin onto the mat and then roll it out to perfection.

Now that you understand that the mat is held together by starch and that you need to dissolve this to get the mat to cooperate it is easy to see why you donít want to use several layers of lighter weight mat to do the same job. More starch! More hassle! Always get the heaviest random weave mat possible. If you need a lighter weight matt just delaminate your heavy weave matt and apply (it pulls apart easily).

Donít poor excessive amounts of resin into an area. Resin is heavy, brittle, and flexible (compared to glass).

After two or three layers of glass (remember that you can apply all of these in one shot), Lay down a core of baltech. Presoak this material on a piece of plastic or cardboard by pooring on the resin and rolling it out. Then place it over subsequent layers of glass. Roll it out. Use two or three layers of this on large sub boxes. Next layer on more glass mat just like before.

After you have three layers of glass, two or three layers of baltech, and another three layers of glass you should wait for a couple of hours for it to cure throughly. Then assess the strength of your project. You will find that you have a steel like structure that is thin and comparitively light weight.

Its worth mentioning that the baltech only needs to be applied on the large flat surfaces. Donít worry about curved surfaces because they are exponentially stronger.

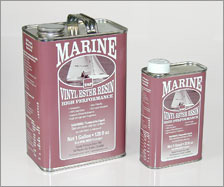

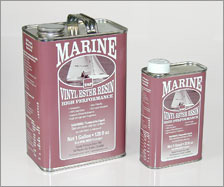

Donít use polyester resin for lay up.

Use vinyl-ester resin. This will cost you about $8 more per gallon (I pay $58 a gallon) but it will wet out so much better that you will use less and it is so much stronger that you will need less layers and you will end up with a thinner lighter weight end product.

Vinyl-ester resin will cure in the same amount of time. It uses the same hardener (mekp) And uses the same mix ratio. Donít put your vinyl-ester project in the sun while curing. The ultraviolet sun rays will screw with the resin and create delaminating problems. Just keep it out of direct sun light until you are done laminating. After that you can stick it in the sun if you like. During cold weather you can put your project under a heat lamp to shorten cure time.

Last but not least get your self a 5 gallon bucket (with lid) and pour three gallons of acetone into it. Keep your rollers and brushes here. When you are not using these items they should live here. Rollers will last for years and disposable brushes will last for months. Also donít worry about contaminating your resin with the acetone. Any acetone that is in your brush or roller will evaporate quickly and will have little to no effect on your project.

Check out www.tapplastics.com

and

www.westsystem.com

for fiberglass products and more information

I hope this helps

Printable version

Printable version

When I see fiberglass projects from other people I always see the same mistakes.

1. Not enough layers

2. Too much resin

3. Lack of core material

4. The use of the wrong type of resin

Sub boxes need to be as strong as possible. You can not do too many layers! The stronger your enclosure is the more efficient your sub will be. The tricks of the trade involve using 1.5 oz. Random Stranded mat or higher, using a roller, balteck mat as a core, and using vinyl-ester instead of polyester resin.

When done right you can lay 7 layers or so in one shot and get a lightweight nearly bullet proof shell.

When I see fiberglass projects from other people I always see the same mistakes.

1. Not enough layers

2. Too much resin

3. Lack of core material

4. The use of the wrong type of resin

Sub boxes need to be as strong as possible. You can not do too many layers! The stronger your enclosure is the more efficient your sub will be. The tricks of the trade involve using 1.5 oz. Random Stranded mat or higher, using a roller, balteck mat as a core, and using vinyl-ester instead of polyester resin.

When done right you can lay 7 layers or so in one shot and get a lightweight nearly bullet proof shell.

Use 1.5 oz random weave stranded mat or heavier. Mat is held together by starch. When weted out with resin the starch breaks down and the mat turns into chop (nothing holding it together). This allows you to make the mat conform to any shape with out those pesky little stands poking out. The key to breaking down the starch is giving the resin solvents a little time (3 minutes or so) and the physical motion of rolling out the resin soaked mat with a roller. I cant stress the roller part enough! The roller will force the resin down into the mat and once the starch breaks down It will force the mat to compact and excess resin will rise to the top. At this point you can lay down more mat to soak up that extra resin. It now becomes apparent just how far resin can really stretch. Much farther than you thought! F the brush! Just use it to get the resin onto the mat and then roll it out to perfection.

Use 1.5 oz random weave stranded mat or heavier. Mat is held together by starch. When weted out with resin the starch breaks down and the mat turns into chop (nothing holding it together). This allows you to make the mat conform to any shape with out those pesky little stands poking out. The key to breaking down the starch is giving the resin solvents a little time (3 minutes or so) and the physical motion of rolling out the resin soaked mat with a roller. I cant stress the roller part enough! The roller will force the resin down into the mat and once the starch breaks down It will force the mat to compact and excess resin will rise to the top. At this point you can lay down more mat to soak up that extra resin. It now becomes apparent just how far resin can really stretch. Much farther than you thought! F the brush! Just use it to get the resin onto the mat and then roll it out to perfection.

Now that you understand that the mat is held together by starch and that you need to dissolve this to get the mat to cooperate it is easy to see why you donít want to use several layers of lighter weight mat to do the same job. More starch! More hassle! Always get the heaviest random weave mat possible. If you need a lighter weight matt just delaminate your heavy weave matt and apply (it pulls apart easily).

Now that you understand that the mat is held together by starch and that you need to dissolve this to get the mat to cooperate it is easy to see why you donít want to use several layers of lighter weight mat to do the same job. More starch! More hassle! Always get the heaviest random weave mat possible. If you need a lighter weight matt just delaminate your heavy weave matt and apply (it pulls apart easily).

Donít poor excessive amounts of resin into an area. Resin is heavy, brittle, and flexible (compared to glass).

After two or three layers of glass (remember that you can apply all of these in one shot), Lay down a core of baltech. Presoak this material on a piece of plastic or cardboard by pooring on the resin and rolling it out. Then place it over subsequent layers of glass. Roll it out. Use two or three layers of this on large sub boxes. Next layer on more glass mat just like before.

After you have three layers of glass, two or three layers of baltech, and another three layers of glass you should wait for a couple of hours for it to cure throughly. Then assess the strength of your project. You will find that you have a steel like structure that is thin and comparitively light weight.

Its worth mentioning that the baltech only needs to be applied on the large flat surfaces. Donít worry about curved surfaces because they are exponentially stronger.

Donít poor excessive amounts of resin into an area. Resin is heavy, brittle, and flexible (compared to glass).

After two or three layers of glass (remember that you can apply all of these in one shot), Lay down a core of baltech. Presoak this material on a piece of plastic or cardboard by pooring on the resin and rolling it out. Then place it over subsequent layers of glass. Roll it out. Use two or three layers of this on large sub boxes. Next layer on more glass mat just like before.

After you have three layers of glass, two or three layers of baltech, and another three layers of glass you should wait for a couple of hours for it to cure throughly. Then assess the strength of your project. You will find that you have a steel like structure that is thin and comparitively light weight.

Its worth mentioning that the baltech only needs to be applied on the large flat surfaces. Donít worry about curved surfaces because they are exponentially stronger.

Donít use polyester resin for lay up.

Use vinyl-ester resin. This will cost you about $8 more per gallon (I pay $58 a gallon) but it will wet out so much better that you will use less and it is so much stronger that you will need less layers and you will end up with a thinner lighter weight end product.

Vinyl-ester resin will cure in the same amount of time. It uses the same hardener (mekp) And uses the same mix ratio. Donít put your vinyl-ester project in the sun while curing. The ultraviolet sun rays will screw with the resin and create delaminating problems. Just keep it out of direct sun light until you are done laminating. After that you can stick it in the sun if you like. During cold weather you can put your project under a heat lamp to shorten cure time.

Last but not least get your self a 5 gallon bucket (with lid) and pour three gallons of acetone into it. Keep your rollers and brushes here. When you are not using these items they should live here. Rollers will last for years and disposable brushes will last for months. Also donít worry about contaminating your resin with the acetone. Any acetone that is in your brush or roller will evaporate quickly and will have little to no effect on your project.

Check out www.tapplastics.com

and

www.westsystem.com

for fiberglass products and more information

I hope this helps

Donít use polyester resin for lay up.

Use vinyl-ester resin. This will cost you about $8 more per gallon (I pay $58 a gallon) but it will wet out so much better that you will use less and it is so much stronger that you will need less layers and you will end up with a thinner lighter weight end product.

Vinyl-ester resin will cure in the same amount of time. It uses the same hardener (mekp) And uses the same mix ratio. Donít put your vinyl-ester project in the sun while curing. The ultraviolet sun rays will screw with the resin and create delaminating problems. Just keep it out of direct sun light until you are done laminating. After that you can stick it in the sun if you like. During cold weather you can put your project under a heat lamp to shorten cure time.

Last but not least get your self a 5 gallon bucket (with lid) and pour three gallons of acetone into it. Keep your rollers and brushes here. When you are not using these items they should live here. Rollers will last for years and disposable brushes will last for months. Also donít worry about contaminating your resin with the acetone. Any acetone that is in your brush or roller will evaporate quickly and will have little to no effect on your project.

Check out www.tapplastics.com

and

www.westsystem.com

for fiberglass products and more information

I hope this helps