Posted: October 06, 2008 at 9:41 PM / IP Logged

Posted: October 06, 2008 at 9:52 PM / IP Logged

Posted: October 07, 2008 at 1:51 PM / IP Logged

Posted: October 11, 2008 at 10:42 PM / IP Logged

Posted: October 17, 2008 at 11:01 AM / IP Logged

Posted: October 19, 2008 at 12:52 PM / IP Logged

Posted: October 19, 2008 at 12:54 PM / IP Logged

Posted: October 25, 2008 at 9:51 PM / IP Logged

Posted: October 26, 2008 at 9:54 PM / IP Logged

Sorry, you can NOT post a reply.

This topic is closed.

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Tuesday, February 3, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Tuesday, February 3, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

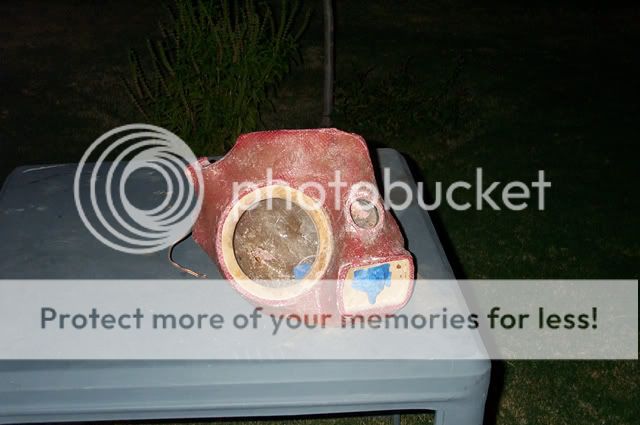

This is the skeleton of my kick panel with the rings (I had to use bondo to stick them cause the super glue wasn't working at all).

This is the skeleton of my kick panel with the rings (I had to use bondo to stick them cause the super glue wasn't working at all). And this is the same picture without the flash...I think its a much better pic :)So yeah once I paint it I will post the finished product on here.This is after the first coat of primer on it. It still has a few dips and pinholes that the spraycan high build primer wasn't doing too good at filling, so I started spraying it on thick.This is after the fleece has been resined. 3M Super 77 spray did a horrible job of keeping the fleece on the 6.5" ring, I had to cut out the piece and redo it and used staples just to get it to stay...This is the same pod with the speakers fitted into them.

And this is the same picture without the flash...I think its a much better pic :)So yeah once I paint it I will post the finished product on here.This is after the first coat of primer on it. It still has a few dips and pinholes that the spraycan high build primer wasn't doing too good at filling, so I started spraying it on thick.This is after the fleece has been resined. 3M Super 77 spray did a horrible job of keeping the fleece on the 6.5" ring, I had to cut out the piece and redo it and used staples just to get it to stay...This is the same pod with the speakers fitted into them.

_.jpg) I painted the inner part of the rings a matte black since the inner part will slightly show through the speaker grill and the bottom of the crossover (which won't really be noticable since its so low and facing straight).

I wasn't really too concerned with the smooth finish on the inner part of the rings since, well they wont really show much anyway, just maybe the edges.

Right now I am clear coating the kick panel :)

I painted the inner part of the rings a matte black since the inner part will slightly show through the speaker grill and the bottom of the crossover (which won't really be noticable since its so low and facing straight).

I wasn't really too concerned with the smooth finish on the inner part of the rings since, well they wont really show much anyway, just maybe the edges.

Right now I am clear coating the kick panel :) The pictures never seem to work for me on these forums.

The pictures never seem to work for me on these forums.