Posted: September 12, 2011 at 8:25 PM / IP Logged

Posted: September 12, 2011 at 8:29 PM / IP Logged

Posted: September 13, 2011 at 3:43 AM / IP Logged

Posted: September 13, 2011 at 11:47 AM / IP Logged

Posted: September 13, 2011 at 1:23 PM / IP Logged

Posted: September 15, 2011 at 11:27 PM / IP Logged

Posted: September 16, 2011 at 12:58 AM / IP Logged

Posted: September 17, 2011 at 3:11 AM / IP Logged

Posted: September 17, 2011 at 3:13 AM / IP Logged

Posted: September 17, 2011 at 3:43 AM / IP Logged

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Friday, December 19, 2025 • Copyright © 1999-2025 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Friday, December 19, 2025 • Copyright © 1999-2025 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

additionally, the flasher module i'm looking at is this one (i am not promoting the brand at all, merely asking for advice on wiring, and products http://www.ebay.ca/itm/4x-4W-LED-WHITE-Flash-Strobe-Light-Headlight-USA-SELLER-/400225987719?pt=Motors_Car_Truck_Parts_Accessories&hash=item5d2f53ec87

additionally, the flasher module i'm looking at is this one (i am not promoting the brand at all, merely asking for advice on wiring, and products http://www.ebay.ca/itm/4x-4W-LED-WHITE-Flash-Strobe-Light-Headlight-USA-SELLER-/400225987719?pt=Motors_Car_Truck_Parts_Accessories&hash=item5d2f53ec87

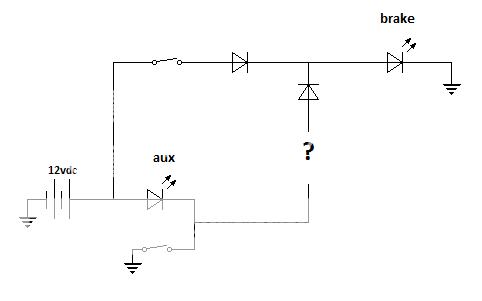

ok, additional question, i want the brake lights to flash along with the led strobes, so here's the situation i'm thinking is going to come up, right now, none of this hardware, except for the top switch exists, it's all new parts that are going to be coming... i'm also not sure if it is a switched ground, or switched positive... i have a set here right now that are a switched ground, which makes me worry a little...

ok, additional question, i want the brake lights to flash along with the led strobes, so here's the situation i'm thinking is going to come up, right now, none of this hardware, except for the top switch exists, it's all new parts that are going to be coming... i'm also not sure if it is a switched ground, or switched positive... i have a set here right now that are a switched ground, which makes me worry a little...

essentially, the aux light should be looked at as an LED strobe, and i want the brake light to strobe on, at the same time as the aux (not an issue if the brakes over ride it)

this same problem persists with my reverse lights, with how i want to wire them up... what do i put in place of the question mark, that will be able to keep up with the fast strobing? i could use a NO relay with constant power, but i can't see the relay lasting very long with the strobing effect...

essentially, the aux light should be looked at as an LED strobe, and i want the brake light to strobe on, at the same time as the aux (not an issue if the brakes over ride it)

this same problem persists with my reverse lights, with how i want to wire them up... what do i put in place of the question mark, that will be able to keep up with the fast strobing? i could use a NO relay with constant power, but i can't see the relay lasting very long with the strobing effect...