Posted: March 18, 2013 at 2:43 AM / IP Logged

Posted: March 21, 2013 at 11:34 AM / IP Logged

Posted: March 24, 2013 at 12:48 AM / IP Logged

Posted: March 24, 2013 at 9:20 PM / IP Logged

Posted: March 29, 2013 at 8:47 PM / IP Logged

Posted: April 06, 2013 at 6:05 PM / IP Logged

Posted: April 13, 2013 at 1:49 PM / IP Logged

Posted: April 13, 2013 at 2:00 PM / IP Logged

Posted: April 14, 2013 at 1:15 PM / IP Logged

Posted: April 15, 2013 at 6:29 PM / IP Logged

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Tuesday, January 6, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Tuesday, January 6, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

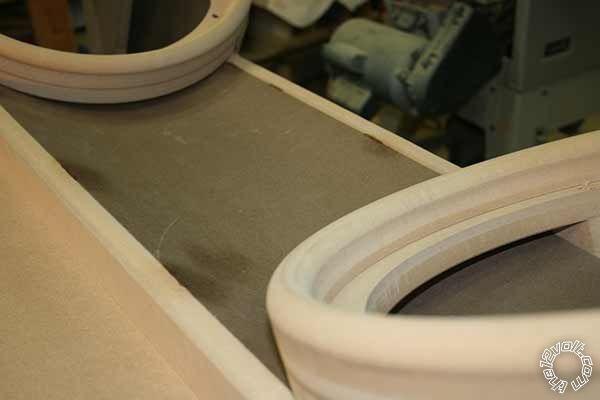

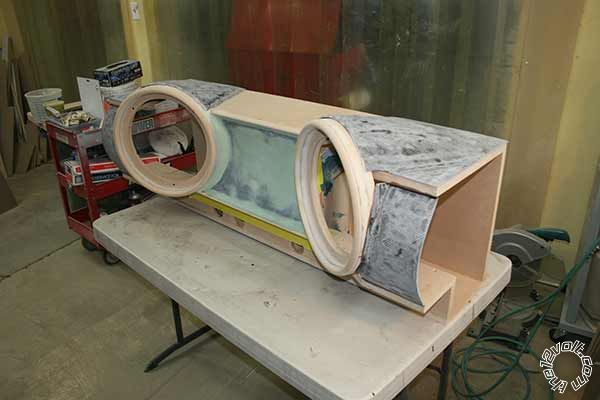

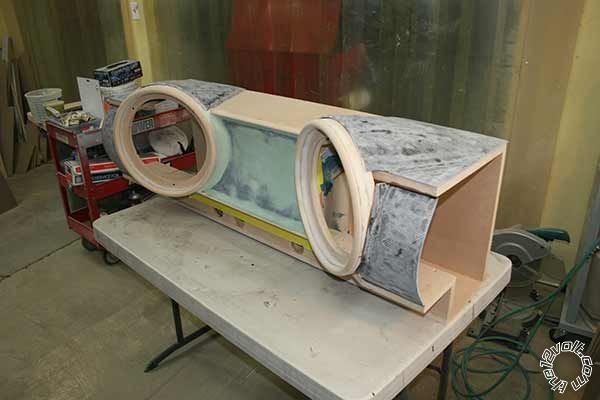

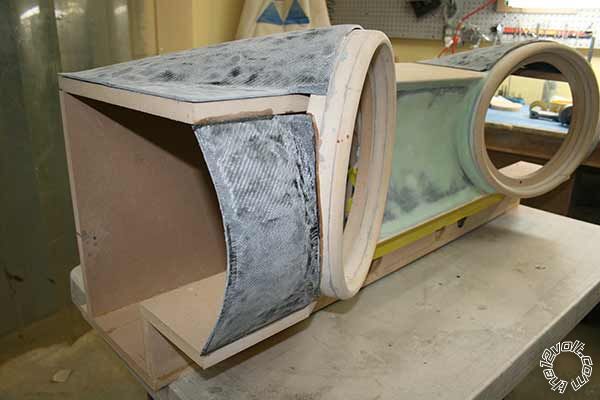

My favorite part of doing it this way is that there is vert little glass and filler to be done on the surface. The back of the chipboard can be reinforced if need be.

Complex shapes that would normally require expensive and time consuming foam can be made this way.

My favorite part of doing it this way is that there is vert little glass and filler to be done on the surface. The back of the chipboard can be reinforced if need be.

Complex shapes that would normally require expensive and time consuming foam can be made this way.

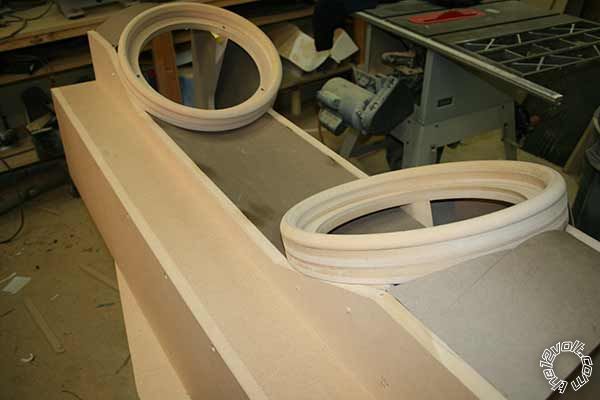

I have found that if you rabbit a grove into the edge of the MDF for the chipboard to sit in you get a nice smooth transition that will need very little effort to glass over seamlessly.

I have found that if you rabbit a grove into the edge of the MDF for the chipboard to sit in you get a nice smooth transition that will need very little effort to glass over seamlessly.

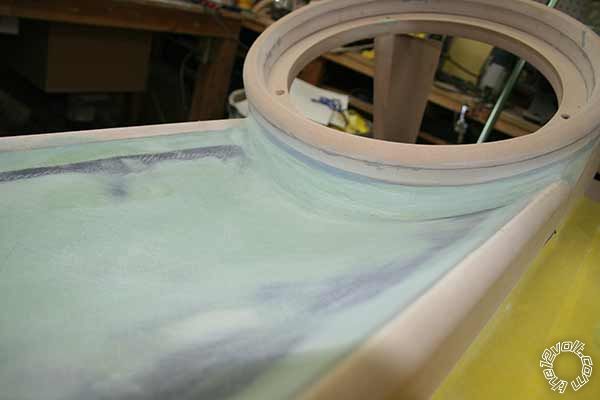

Notice the black fiberglass showing through the green body filler (I use black glass). This is due to the surface being so close to perfect that only a thin layer of filler is required.

I would like thoughts and ideas but if you are a DIY or experimenter please don't pass off opinions as fact. I appreciate all input from creditable sources and all questions or ideas from anyone. Thanks.

Notice the black fiberglass showing through the green body filler (I use black glass). This is due to the surface being so close to perfect that only a thin layer of filler is required.

I would like thoughts and ideas but if you are a DIY or experimenter please don't pass off opinions as fact. I appreciate all input from creditable sources and all questions or ideas from anyone. Thanks.

This was one of those boxes that ended wrapped in suede. I have photos of the process I can also post.

This was one of those boxes that ended wrapped in suede. I have photos of the process I can also post.