Have you considered LEDs for headlights? They only use a few Watts, and are getting reasonably cheap.

Pushbikes use them. I have a few focusable torches that are ~200 Lumen and run off 3x1.5V AAA batteries, ie 4.5V. Though I got my originals for ~AUD$25, my last was $10 from a computer "swap meet" (no used stuff there!) but I've seen them on eBay for ~$4.

I suspect they will be cheaper than your "special" halogen bulbs.

Wire a few in parallel if needed, but on narrow beam, they illuminate

100m with ease.

And I reckon use a 6V flasher can. They are not difficult to make - a timer and a relay. And if you convert your flashers to LEDs, you can omit the relay and drive the LEDs direct else through a transistor.

You could add current sensing to imitate traditional cans (ie, fast flashing if a bulb has failed), but these days the cans for LEDs omit that feature. (LED flasher cans - the new rip-off.)

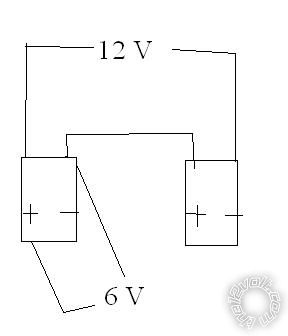

As to the batteries, if 12V is still needed, I suggest a relay to switch them from parallel to series.

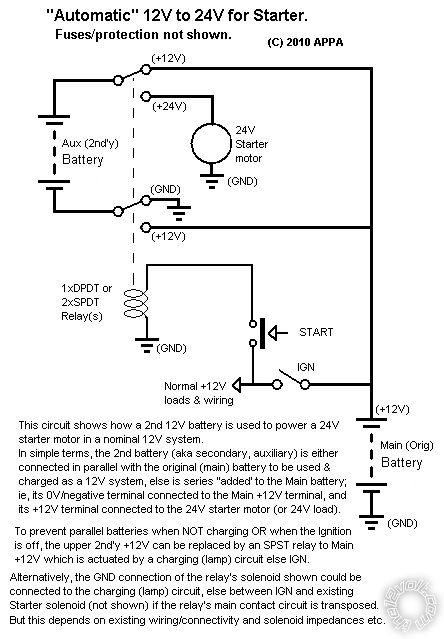

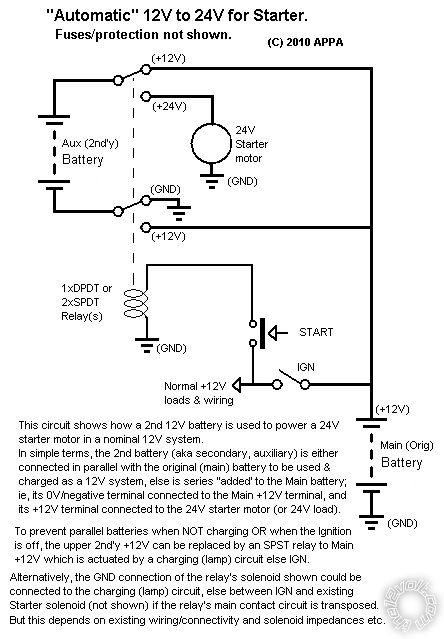

That's been done in

charging two 12v batteries in series for a 24V starter motor, but change to 6V relays and batteries and it's the same. I'll post that link's diagram below. Note that the alternator is not shown - that is connected across the main battery.

Note too that there is no break involved wrt the "main" 6V battery. (I had a brain fart and thought there was, and then thought of a workaround, but then regained sanity.)

The indicator switch would actuate the series to parallel relay.

The main battery would charge as per normal.

The "imbalance" caused by the 2nd battery not being charged - which long term will wreck the battery(s) - is not an issue because, upon being returned to their "normal" parallel connection, the 2nd battery will charge at a higher rate and re-balance. (Yes, in case you have read from the many (sites) that say otherwise, you can parallel dissimilar batteries when they are being charged.)

There is no need for diodes to prevent feedback... there is no feedback. In short, you'll have the "main" 6V battery across the

alternator, and that's that. (The other battery can't "push thru" etc. You'd need a connection from the +12V end to the regulator or something else intimately connected...)

Besides, diodes would create other problems.

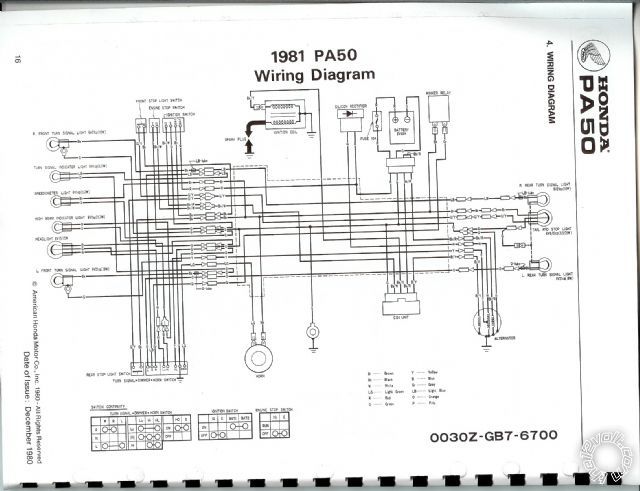

I wonder what your charging system is. Although the lights can be AC, DC must be provided for/to the battery. That can be done by my previously mentioned zenor-diode dumping system, but then I'd expect 2 stator-winding outputs - one for the lights (AC) and another winding for the DC.

A single-circuit system (which can still have multiple stator coils) would have a bride-rectifier (diodes) for the DC after the AC take-off point.

Confused? (Sorry, it's 11:30AM and I've been up all night. Not that that'll make much difference to my writing!)

But in retrospect, I like the LED headlights idea. And why not tails and indicators too? To put LEDs in context, a normal LED uses 40mW (0.04W) - that's 1/75th of a 3W bulb (but a

6V LED is 3x40mW = .12W, & for 12V would be .24W - still ~1/10th of a 12V/3W bulb).

As if this isn't already long enough - now I'm inserting that diagram...

Printable version

Printable version