Oh dear, another oil pumper.

That practice should have died years ago. Yes I know some vehicle manufacturers implemented it as OEM (tho usually as a backup) but they later ceased, and some fools refer to the fly logic "

why do so many people do it then?" (I don't know - ask them!).

Assuming you are using a switch for safety in case of an accident, oil pressure is not that way to do it. Pumps can run on for way too long - I know of engines whose switches remained engaged 40 seconds after stopping.

If you are using it to protect the engine in case of oil failure, fuel cutting is not the answer. Not only can it be dangerous, but it can also cause far greater engine damage - especially on carbied or surge-tanked engines - ie lean burn & holed pistons; and some argue injector damage). If oil pressure engine protection is the intent you use an ignition kill but that is never AFAIK implemented in vehicles for safety reasons (tho time delay circuits with a manual overrides have been used).

In short, oil pressure controlled fuel pumps are, in general, undesirable as both safety or engine protection methods.

The best simple OEM and add-on systems use the alternator charge light, viz:

... as per

fuel pump which is probably worth a read.

Alternatives - especially where the alternator charge-light circuit may not be able to supply the +12V current required for the relay coil (assuming people don't want to add a MOSFET or transistor buffer) includes air flaps (if fitted to EFI etc systems).

Otherwise oil pressure is better than an IGN only powered fuel pump, but as above, that is not generally appropriate for engine protection nor safety and it is considered dangerous. (Why does low oil pressure usually trigger an idiot light and NOT an engine kill?)

Of course EFI EMS's should have fuel pump control tho some do not (eg, old Bosch and VAGs). (Even some of those still use the oil pressure switch as a backup - IOW even if the EMS kills the pump, the pump can keep running...)

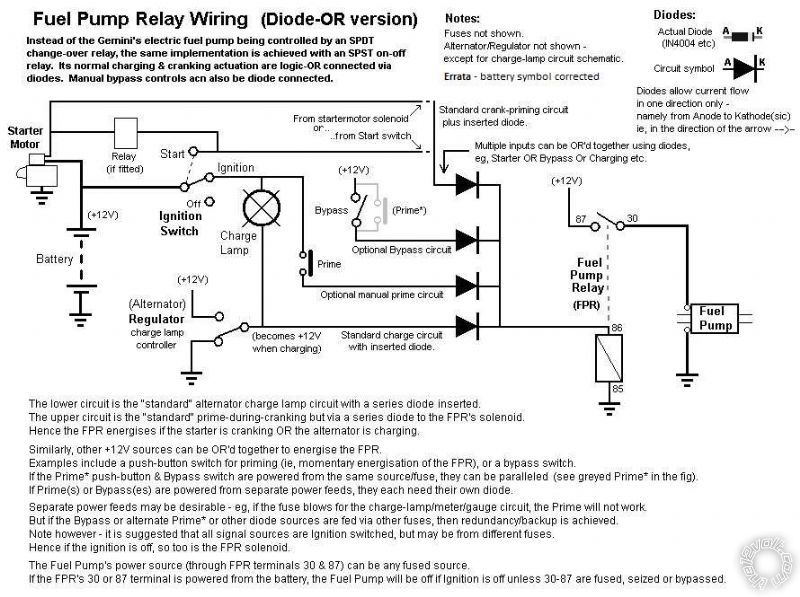

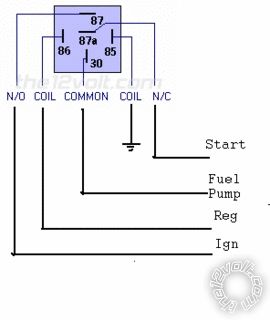

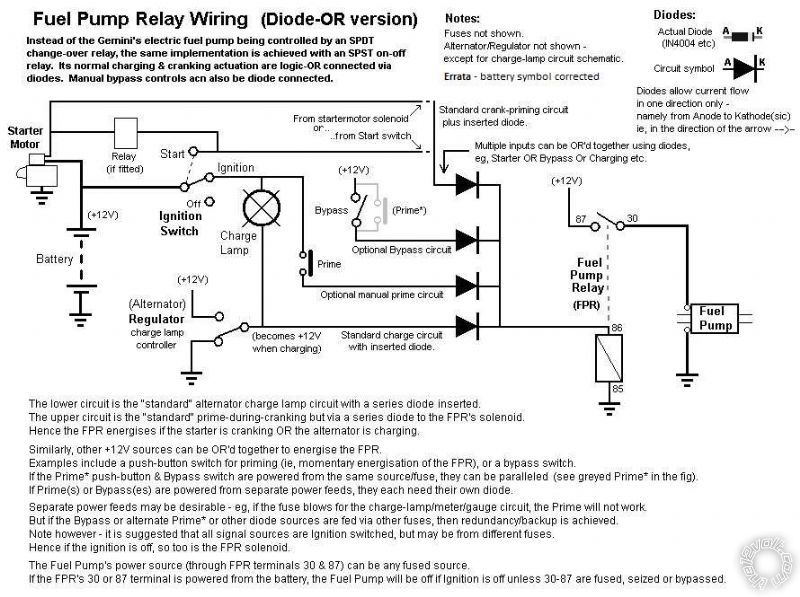

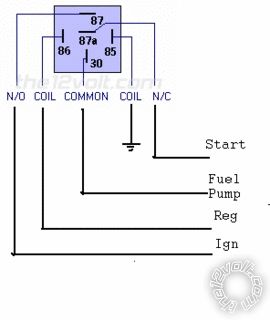

And FYI - tho using an SPDT relay as per the above diagram requires only the relay (and charge-light circuit) to provide fuel during cranking and engine running, I prefer SPST wiring using diodes (even tho I use SPDT relays for all SPST relay applications).

That enables other controls to be added - eg, a momentary switch for per-crank priming or toggle switch to milk the tank etc.

And note that should the alternator fail, the relay can be activated by disconnecting the alternator's voltage regulator - ie, disconnect its D+ or L output by disconnecting the alternator's

small connector if it's a newer

all in one internally regulated type, or disconnect the voltage regulator if an external type. The dash charge light and other connected "IGN-on test" bulbs should be enough to energise the relay for limp-home mode.

For SPST with diode examples see

here tho below is a better quality and corrected version (the original battery symbol was incorrect).

FYI - similar and additional info exists under UIBI

aka Ultimate Intelligence Battery Isolator threads. In my case the UIBI was inspired from the above simple SPDT relay diagram - a battery isolator being exactly the same in principle as electric fuel pump & choke etc controls but without the crank priming (except when dual batteries are desired for cranking).

Printable version

Printable version

... as per

... as per