I kept myself busy with improving the diaphragm. The biggest problems are gone, and I'm satisfied how it all works now.

The first thing I need to have, was a good slider/conductor where the nylon wire slides over when the diaphram opens and closes.

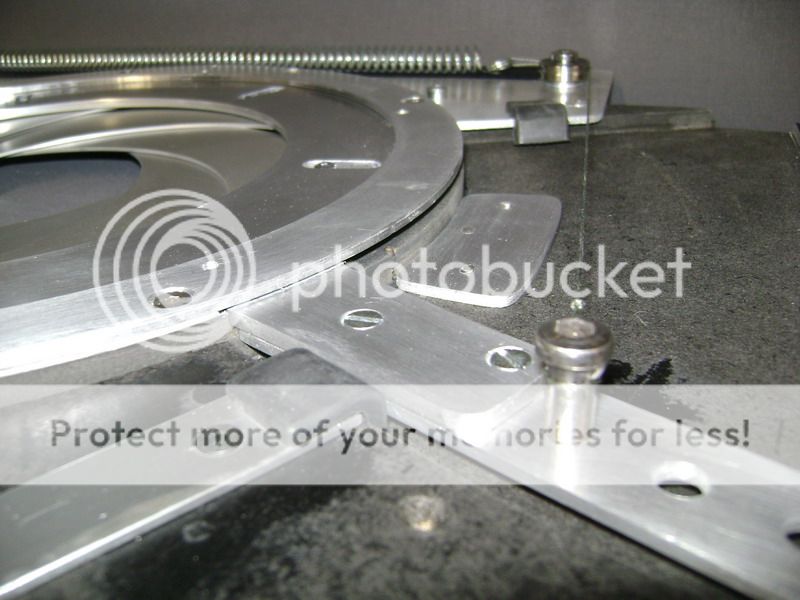

Cause a roller would be perfect for the job, I editted one with the disc.

The meaning of this was that I needed a sloth where the cable nicely stays in turn.I immediately put a screw in the roller with the propper roundels so it all was TIGHTEN.

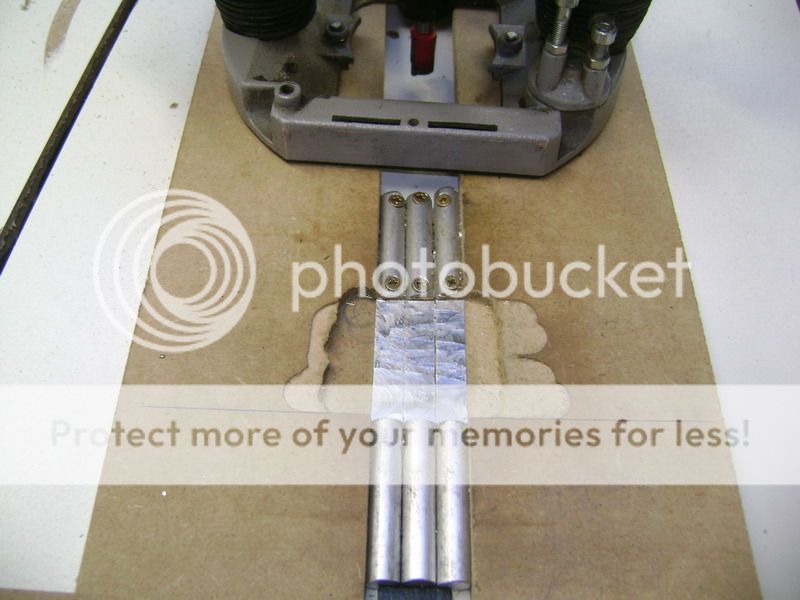

The I put it in my drilling machine, and put in the center of my mill.

As you can see, fireworks were early this year :-) but it went perfect.

After that I just let it turn, and held a piece of sandpaper against it, to smoothen' it some more.

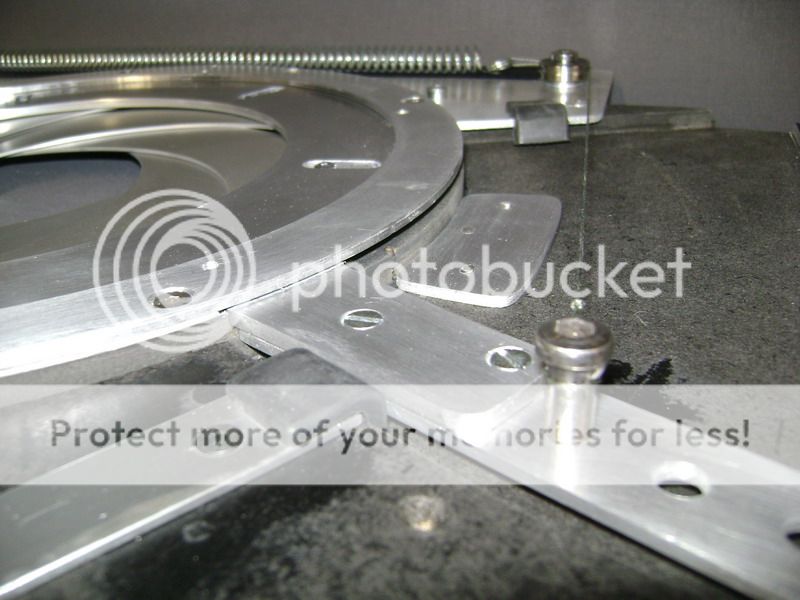

On the left you can see the roller, tuned by Robolop.

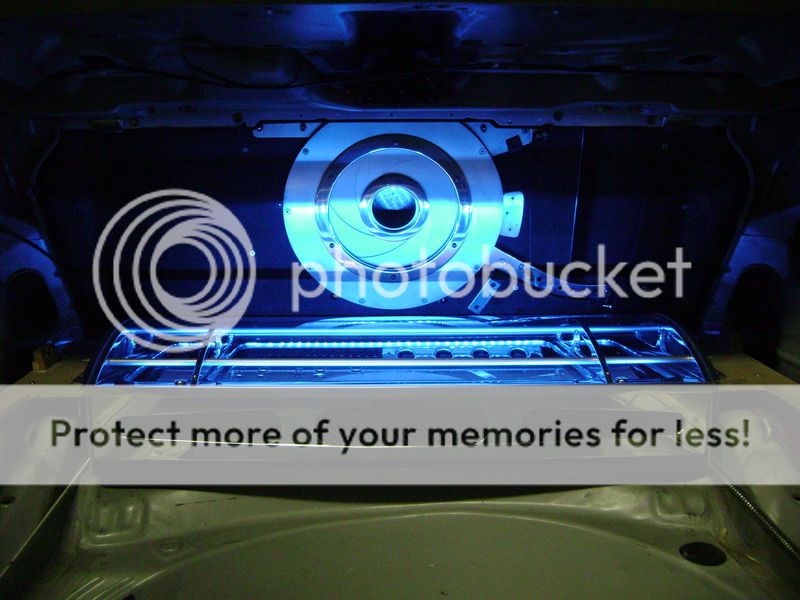

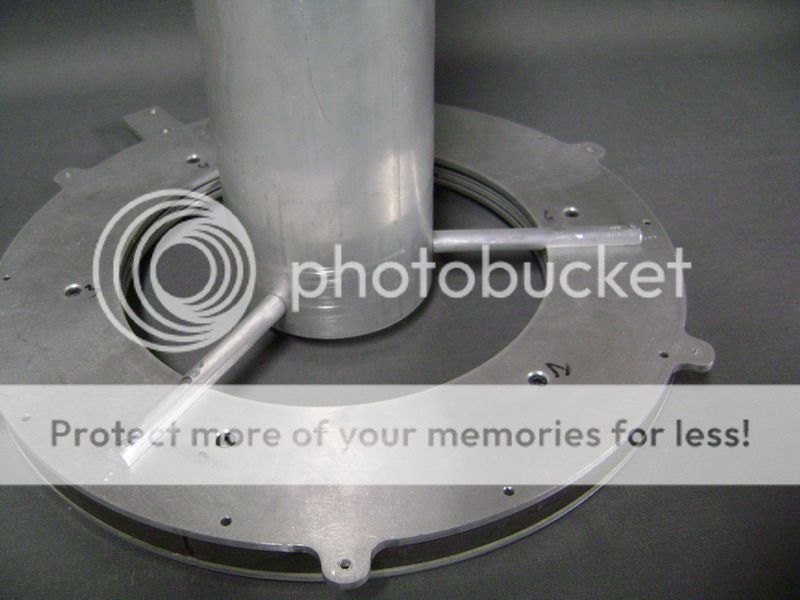

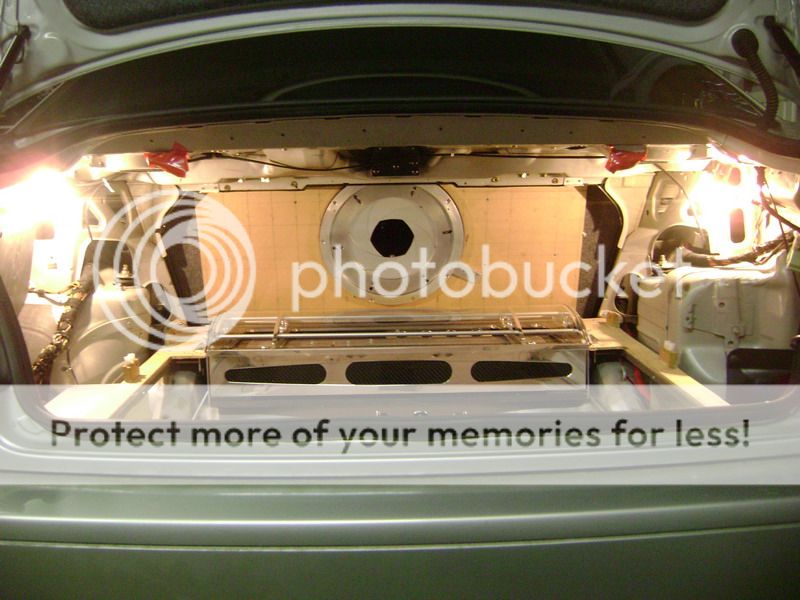

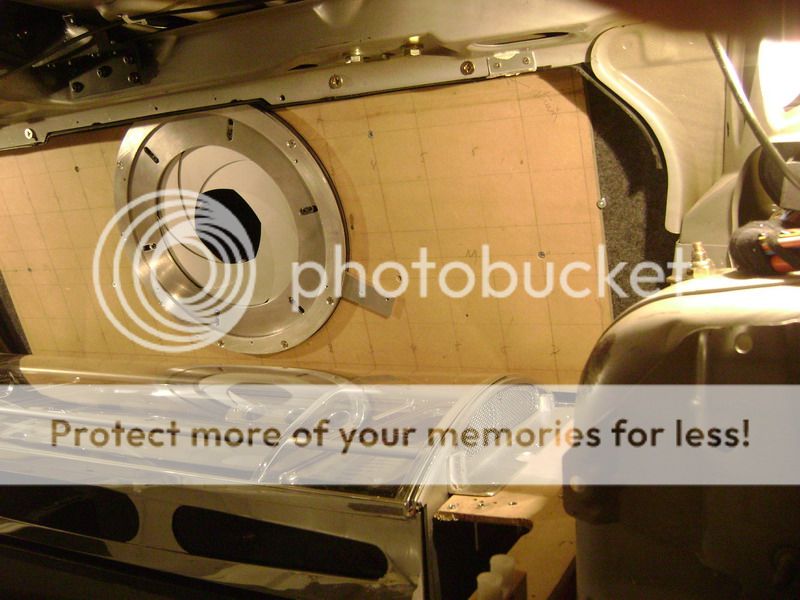

Here you can see the total picture of the MDF board as it'll come into the trunk.

My biggest concern is the spring. I really want to get this out of sight. Since I had some place between the seat I put it there.

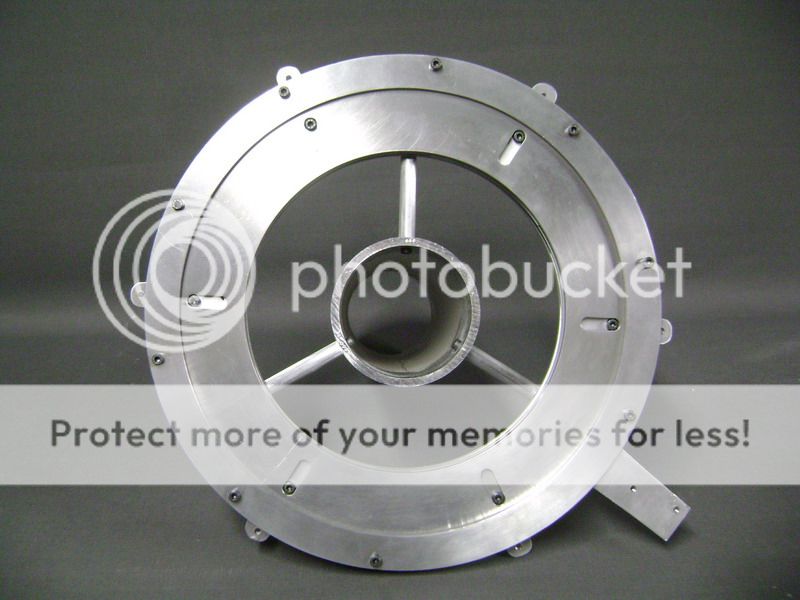

I had to make a seperate piece of aluminum to mount it all on. To do this, I first had to tighten the MDF on the back of the rearseat, and after that I could screw on the aluminum.

I had to make this in 2 pieces, cause it all was to big to get in between.

Underneath the spring, I taped a piece of vilt, so it can't make any noise. I'm planning of adding something around the spring to reduce vibration and noise towards zero.

Here you can see the tuned roller, within the cable, that's in connection with the lever.

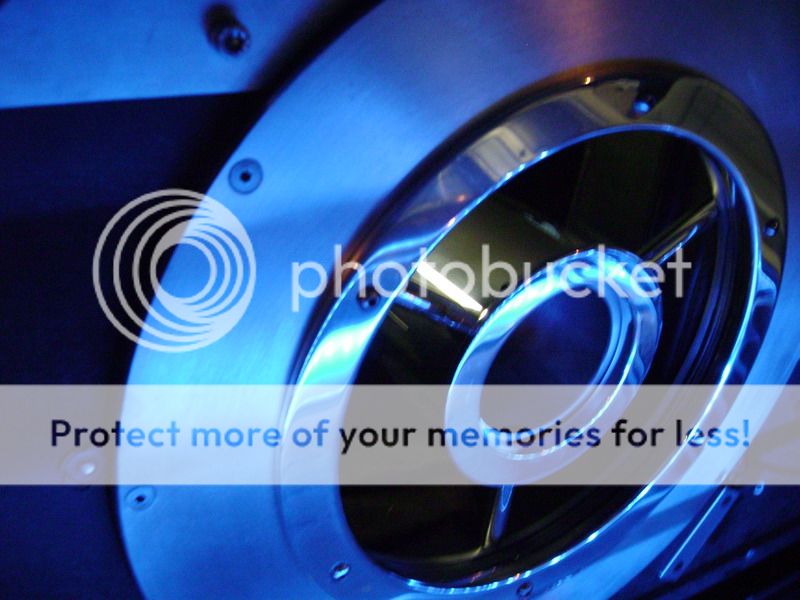

†Here you can see it working when closed.

†

You can also see I added some rubbers, where the lever stops.

Here the inox-cable will lay into, witch stands in connection with the windowwipermotor.

†

The motor is already firmly tightened in the trunk, besides the end loop contacts, it's all ready to mount in the bimmer.

As for now, I'm really satisfied with how it all works and looks.

This I cannot say about Marilyn Manson his performance yesterday in the Lotto Arena here in Belgium.

The donut hole didn't feel like performing according to me, he stopped after an hour.

the loser.

Printable version

Printable version

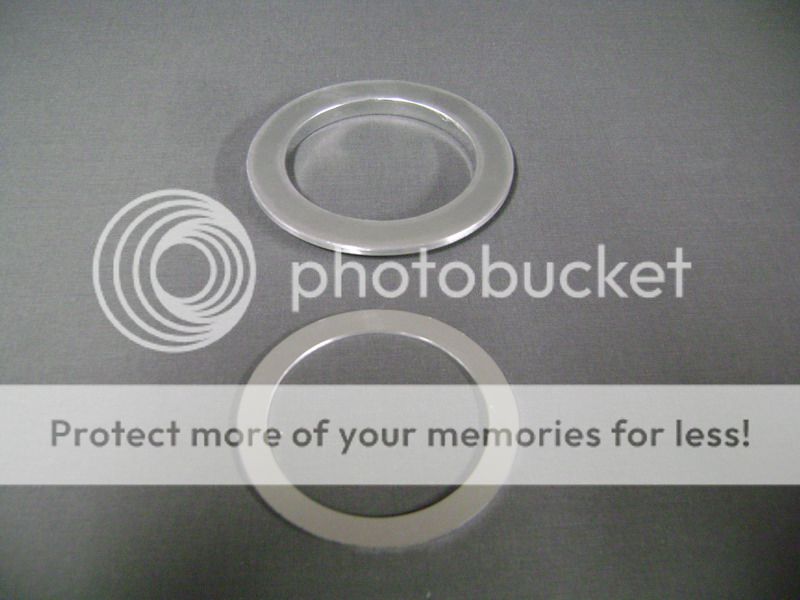

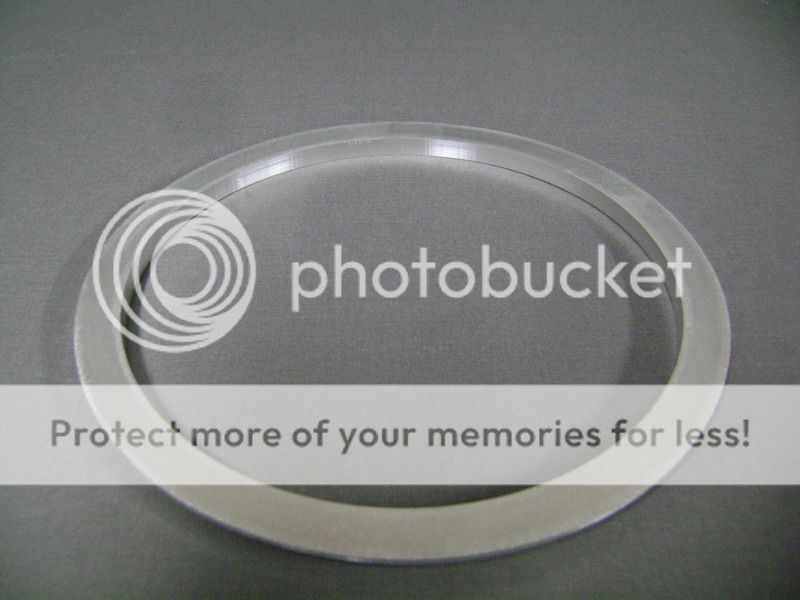

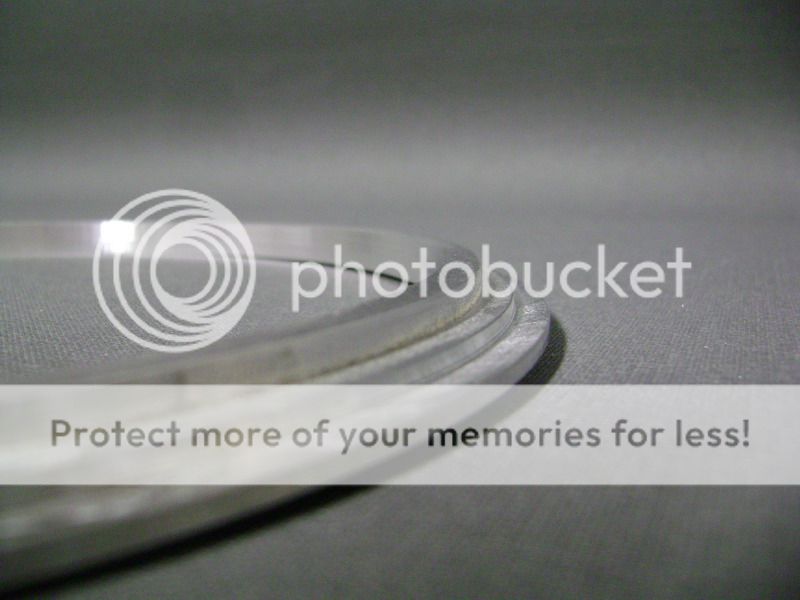

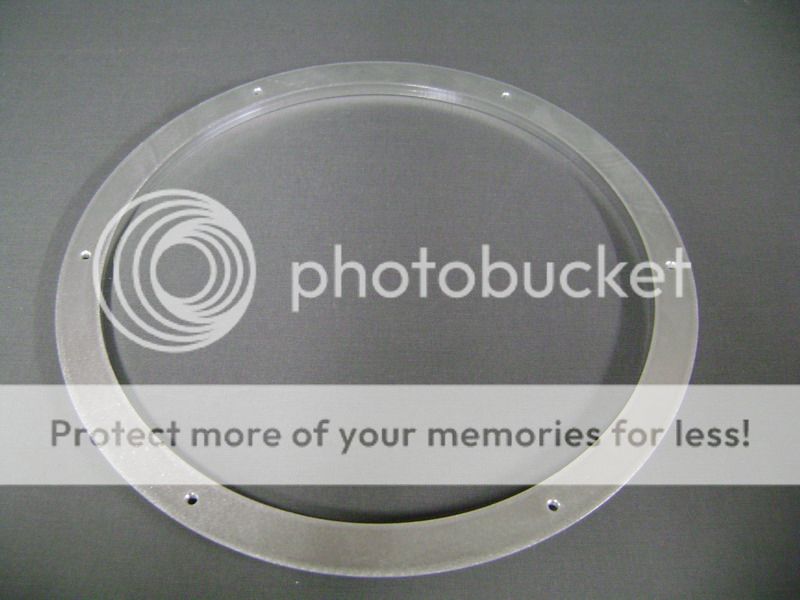

The inner ring stayed the same.

The inner ring stayed the same.