Oh Man, you're going to kick yourself after the next few lines... (of text, not recreational powders!)

But first I'd like to repeat "welcome to electronics" (and maybe stress my aforementioned

condolences {LOL}), AND add that I was impressed by your work above - including that "101" link.

In fact, no, maybe I won't tell you. You were tired, and then away. That's a rude interruption to your thinking processes yadda yadda... (That's right isn't it?)

Two ways I can tackle it...

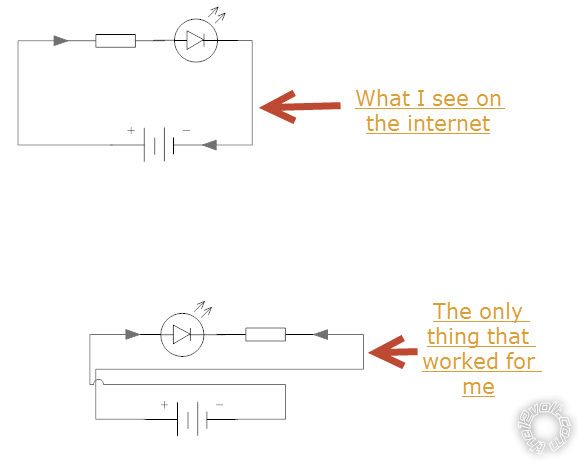

The first is coupled with a diode & LED circuit and wiring trick.

The diode symbol is a line and arrow like --->|---

So what?

Well, that symbol has it all...

The

arrow points in the direction of the current flow.

[ +ve to -ve, ie (+) +ve ---->|--- -ve (-) so current here flows left to right thru the diode. ]

The other main thing is that it's (vertical or perpendicular) line is the BAND on the diode body, hence the diode's "band" end points to the more -ve voltage if you want it to conduct. (They can be mounted "back to front" for voltage limiting or spike suppression. Forget that for now, but

later maybe look at the spike suppression diode placed across relay coils (86 & 85). I/we might discuss that

later.)

A trivial thing from the diode "arrow & band" symbol is that ruddy Anode (+ve) and Cathode (-ve) jargon. (I couldn't even remember which meant +ve (anode) or -ve until, perhaps(!?), recently.)

The lile end is a "K" - ie, ---|<--- = ---K--- to that's the Kathode = Cathode end.

Ergo, the other end is the anode, but that's confirmed by the arrow head > which is a sideways A.

Well that's how I remember it. And that's how I could tell people that the anode is the +ve end - ie, working backwards, I knew current traveled +ve to -ve thru the diode hence into the arrow and out of the line/band, +ve so into the arrow = A hence +ve is the anode.

A pause or digression here. Part way thru the above text I thought

here I go again - a long reply for a potential one line (7 word) simple answer. And that was before the last block about how I determine +ve = Anode!

But I'm in my typical "101"

ramble teaching mode - even though many could figure most out from a simple answer.

Okay, so applying the above to LEDs.

As you said, LED is merely a diode, but it emits light. Hence the LED symbol is a diode with a couple of squiggle-arrows off it to symbolise the emission of photons/light.

[ FYI - voltage-drop = "forward voltage drop" ramble:... IE - optional; skip this for later...

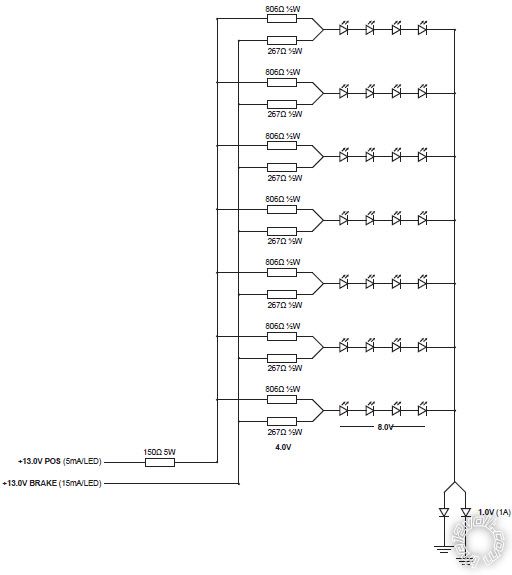

Of course diodes have a forward voltage drop and that drop depends on the type of diode or color of LED, as well as the amount of current thru it.

Common silicon diodes typically have a 0.6 - 0.7V forward voltage drop whilst older germanium types were ~0.2V. New "fast" Schottky diodes are ~0.3V. (As to the current effect, a high-current silicon diode's voltage drop may be 0.6V at low current, and over 1.0V at high current (eg, 100A).)

LEDs vary from typical reds with ~1.7V to whites with ~3.4V.

BTW - the reverse blocking voltage should be infinity - ie, NOT let "reverse" current thru no matter what the voltage is - but in practice there is a "reverse breakdown voltage" which does simple means the

reverse voltage at which the diode will break down (ie, conduct, or self-destruct, etc). LEDs may have low reverse breakdown voltages (hence they may need a normal diode in series for AC power etc), but silicon diodes are usually 50V upwards. For 12V automotive systems 50V diodes (eg, 1N4001) should be fine, but usually the more common 1N4004 with 400V PIV (Peak Inverse Voltage) is used. The 1N4 series has a 1A rating (max forward current) and the last digits designate their PIV (but with no direct numerical relationship other than increasing, eg, 1N4001, 1N4002, 1N4004, 1N4007 have 50V, 100V, 400V & 1,000V max reverse voltages (PIVs) respectively. The missing numbers are other voltages that are no longer produced, but essentially the 1N4004 (400V) & 1N4007 (1kV) are the only two still in common production and supply. The 400V 1N4004 rating is better suited to automotive 12V systems anyway since a vehicle can have high-voltage spikes of 200V etc.

/end vd ramble

]

Anyhow, back to your problem of LEDs in series.

Draw a few diode symbols in series.

Now think

how could you connect them so that they all pass current in the same direction? IE - which way do the arrows point? Then compare that to what you wrote in the first line of your last reply...

Kicking yourself yet?

You had the answer - a diode "the wrong way around" blocks the current. (Or as I say,

it hits a brick wall - ie, the line or band.)

[ More optional ramble

Incidentally (again!), you may know that the current thru all series components is the same (it has to be - where else can the current go?). And (therefore or hence...) the sum (total) of all the voltages across each component adds up to equal the supply voltage.

Hence your resistor should still carry (say) 20mA but at a lower voltage when there is more than one LED

in series (not parallel!!).

That means a lower resistor, but the

single LED's resistor should still work fine. (LED dimness is NOT proportional to the resistance. But that's another topic. Put is this way, LEDs are NOT amongst the first things to be taught in electronics though they may be covered early on because they are great to use in circuits, but few understand LED characteristics. In fact I still have colorful

discussions regarding LEDs - usually along the lines of how critical there AREN'T wrt to voltage, and to an extent, current.

/end ramble

]

Maybe I should have started with the second way I could tackle your problem, but it might be a spoiler if you haven't kicked yourself yet...

Think about how other "polar" devices are connected, eg:...

How do you align batteries in torches and remotes etc?

How do series magnets align themselves?

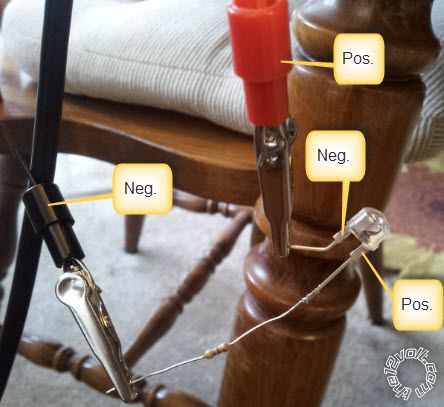

BTW - I haven't gotten further on your possible "faulty" LED. I've bee meaning to search for instances of backward constructed LEDs - like the car battery I mentioned with incorrectly molded + & - terminal labels.

Though

maybe the LED's flat side could be misaligned (IMO still doubtful though), I consider it almost impossible to invert the internal connections to the electrodes (terminals/wires) - ie, the Kathode/-ve should always be to the bigger "flag" electrode (as usually seen looking thru the LED from the side).

Isn't it nice starting off a Sunday with a nice relaxing read?

Till next.... (Sunday?)

Good luck.

Printable version

Printable version