Posted: September 05, 2012 at 1:15 PM / IP Logged

Posted: September 05, 2012 at 2:04 PM / IP Logged

Posted: September 14, 2012 at 4:18 PM / IP Logged

Posted: September 22, 2012 at 4:53 PM / IP Logged

Posted: October 04, 2012 at 1:08 PM / IP Logged

Posted: October 05, 2012 at 1:18 PM / IP Logged

Posted: October 05, 2012 at 1:23 PM / IP Logged

Posted: October 05, 2012 at 2:00 PM / IP Logged

Posted: October 09, 2012 at 12:23 PM / IP Logged

Posted: October 22, 2012 at 12:51 PM / IP Logged

Printable version

Printable version

| You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

| Search the12volt.com |

Follow the12volt.com

Tuesday, March 3, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Tuesday, March 3, 2026 • Copyright © 1999-2026 the12volt.com, All Rights Reserved • Privacy Policy & Use of Cookies

Disclaimer:

*All information on this site ( the12volt.com ) is provided "as is" without any warranty of any kind, either expressed or implied, including but not limited to fitness for a particular use. Any user assumes the entire risk as to the accuracy and use of this information. Please

verify all wire colors and diagrams before applying any information.

stated with a fiberglass base.

stated with a fiberglass base.

The speaker rings are router-ed from 2 pieces of 1/2" mdf glued together.

my goal was to mount the as deep as possible into the panel so the pods wouldn't block my view.

The speaker rings are router-ed from 2 pieces of 1/2" mdf glued together.

my goal was to mount the as deep as possible into the panel so the pods wouldn't block my view.

Mixed up some JB-Weld to put over the screw heads to secure them to the pod base plate.

Mixed up some JB-Weld to put over the screw heads to secure them to the pod base plate.

Used a old t-shirt and hot glue to wrap the pods. I was planing to use fleece but the curves and small size of pods made very difficult to rap around. I prefer hot glue over other methods because that way i can use a heat gun to undo any mistakes and later after the resin is harden to remove the cloth as close to the edge of the base plate. ( you will see what i mean in another pic.)

Used a old t-shirt and hot glue to wrap the pods. I was planing to use fleece but the curves and small size of pods made very difficult to rap around. I prefer hot glue over other methods because that way i can use a heat gun to undo any mistakes and later after the resin is harden to remove the cloth as close to the edge of the base plate. ( you will see what i mean in another pic.)

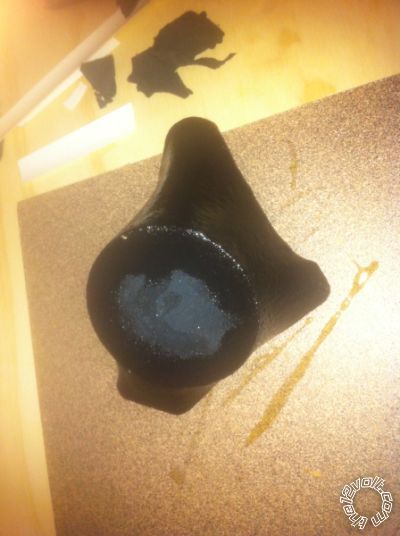

resin is brushed on and harden. downside to using a t-shirt is weakness, fleece will hold more Resin. Next step is to reinforce the pods from the inside with FG and poring resin into the pods.

resin is brushed on and harden. downside to using a t-shirt is weakness, fleece will hold more Resin. Next step is to reinforce the pods from the inside with FG and poring resin into the pods.

Quick test fit to the A-pillar

Quick test fit to the A-pillar

after bondo fully cured. Hand sand it with 120, 200, final 400 grit.

after bondo fully cured. Hand sand it with 120, 200, final 400 grit.

quick test fit

quick test fit

Cleaned up with alcohol and compress air. let it dry off for 10mins or so. Then put 4 light coats of primer 10 mins apart as per can. I used a fast dry primer that was wet sand-able after 20mins :) . Wet sanded with 800 then 1000 grit. Don't for get to soak the sand paper for 30mins at least. Will let them sit for a day or so then its time for the texture paint and clear coat. *note that you don't have to go pass 120 grit sandpaper if you use texture paint, I was undecided on the finish!!!!

Cleaned up with alcohol and compress air. let it dry off for 10mins or so. Then put 4 light coats of primer 10 mins apart as per can. I used a fast dry primer that was wet sand-able after 20mins :) . Wet sanded with 800 then 1000 grit. Don't for get to soak the sand paper for 30mins at least. Will let them sit for a day or so then its time for the texture paint and clear coat. *note that you don't have to go pass 120 grit sandpaper if you use texture paint, I was undecided on the finish!!!!

Sorry for the bad pic. (was taken at night)

Doors are next up.

Sorry for the bad pic. (was taken at night)

Doors are next up.